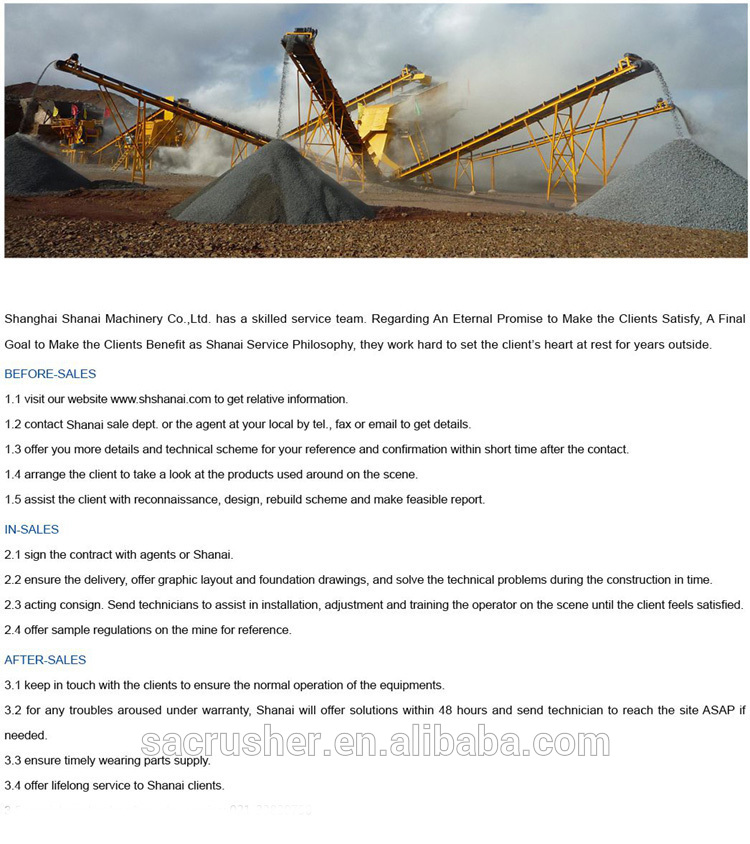

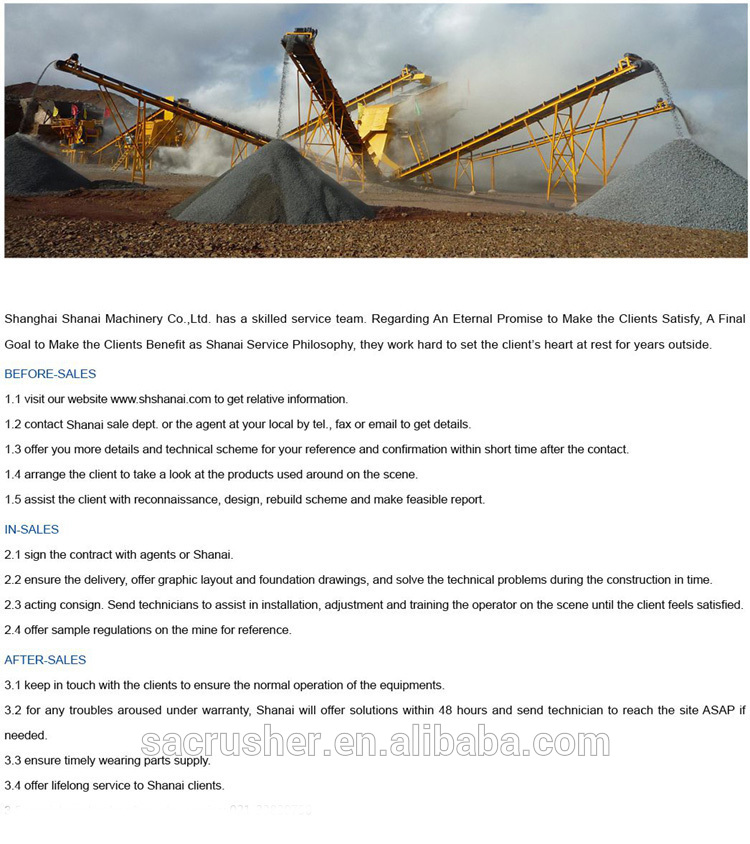

Shanghai Shanai Machinery Co., Ltd.

Basic Information

- Model No.: ore

- Min. Order: 1 Set/Sets

- Payment Type: L/C,T/T

- Packaging: Wooden box

- Delivery Time: 30 Days

- Place of Origin: Shanghai, China (Mainland)

- Brand: SHANAI

- Supply Ability: 30 Set/Sets per Month

High Quality Ore Screen, Ore Screen, Mineral Screen, Stone Vibrating Screen

The vibrating screening machine is a kind of sieving equipment of international advanced level, developed by our company on the basis of carrying on the advantages of traditional screens and absorbing the outstanding technology from abroad. It is widely used for grading and screening materials in the following fields: minerals, quarry, building materials, water conservancy and hydropower, transportation, chemical industry, smelting and so on. Main Features

1.High capacity and reliable

2.Long bearing lifetime 3.Easy to maintenance 4.Multi-layer, and the hole size adjustable Features and Benefits:

The vibrating screen features long flowing line, many screening specifications, strong violent vibration force, high screening efficiency, small vibrating noises, firm and durable construction, convenient maintenance and safe operation. Specification:

APPLICATION APPLICABLE MATERIALS:

Chemicals, Mine, Coal, Granite, Rock, Stone, Marble, Griotte, Calcium Carbonate, Domolite, Limestone, Limerock, Calcareous Stone, Conquina, Siliceous Limestone, Chromite Ore, Mineral, Cement, Concrete, Compound, Cobblestone, Iron Ore, Ironstone, Iron-mineral soils, Copper Ore, Azurite, Copper Sulphide Ore, Quartz Stone, Quartzite, Keli Stone, Silestone, Coal, Gold Ore, Basalt, Whinstone, Shaly, Shale, Mudstone, Nonferrous Metals Ore, etc.

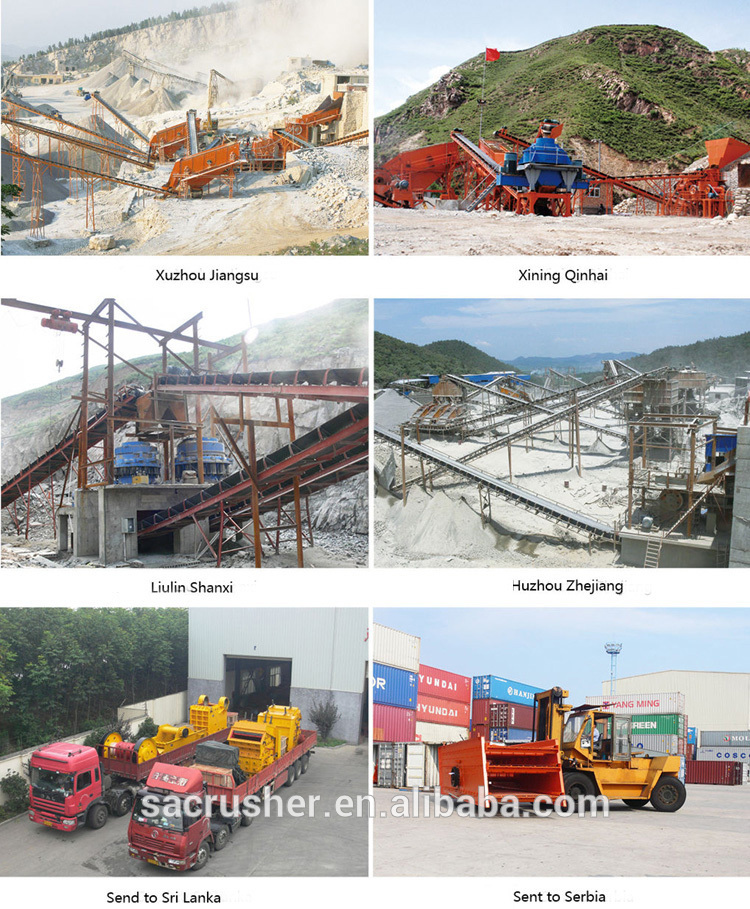

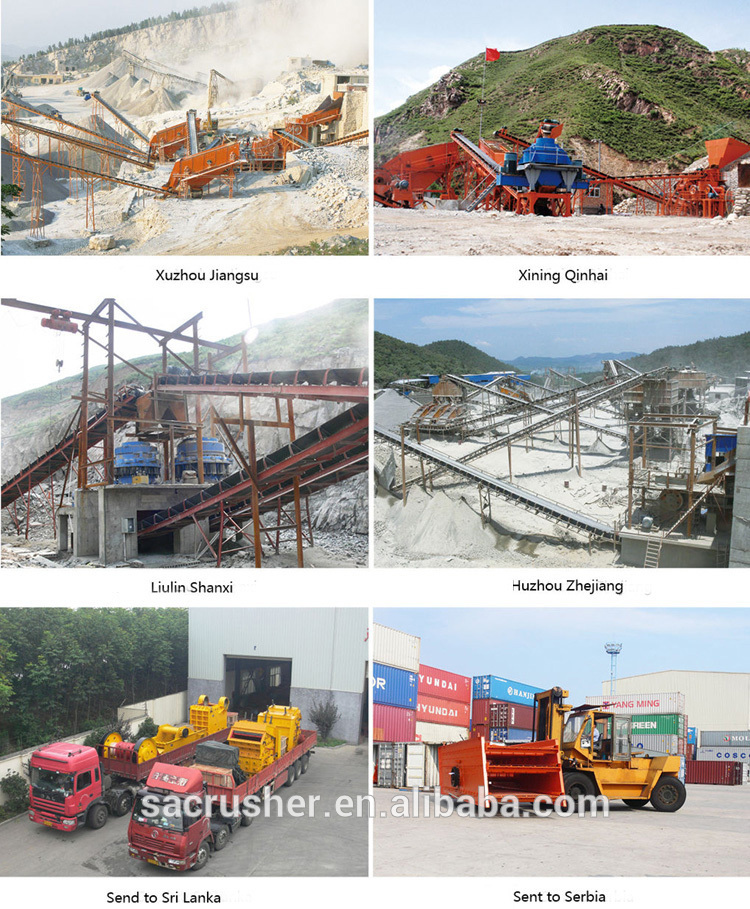

RANGE OF APPLICATIONS: Sand Making Plant, Construction Waste Recycling, Household Waste Processing, Labratory, Quarry, Road, Building, Cement Plant, Building, Highway, Chemical, Metallurge, Coal Mine, Gold Mine, Benification, Mineral Separation, Stone Production, Brick Making, Ore Dressing, etc. ------------------------------------------------------------------------------------------------------------------------------------------- Spareparts Show

OUR MAIN PRODUCTS

OUR MAIN PRODUCTS

ABOUT US

ABOUT US

Why Choose Us?

Why Choose Us?

1. We are Manufacturer (Our Spare Parts Factory is one of the biggest in China): We have complete production line for both spare parts and equipment. All products are made by ourselves, with competitive price, good quality and 7*24 after service plus technical support. 2. Training & Service: 1.We provide you with the pre-installtion scheme plan, process flow design and manufacturing as per your request. 2.Send technicians to the jobsite for installation guidance and adjustment, training operators if you need. 3.Have stock for regular spare parts and machineries, which means the delivety takes shorter time. 3. If you are new in this business: We can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments. 4. We’d be glad to recommend suitable machine for you with best price. So please try to give us more information about your requirement, such as: ♦ What is the type and size of raw material? ♦ What is required size of final product(mm)? ♦ What is production capacity you want?

The vibrating screening machine is a kind of sieving equipment of international advanced level, developed by our company on the basis of carrying on the advantages of traditional screens and absorbing the outstanding technology from abroad. It is widely used for grading and screening materials in the following fields: minerals, quarry, building materials, water conservancy and hydropower, transportation, chemical industry, smelting and so on. Main Features

1.High capacity and reliable

2.Long bearing lifetime 3.Easy to maintenance 4.Multi-layer, and the hole size adjustable Features and Benefits:

The vibrating screen features long flowing line, many screening specifications, strong violent vibration force, high screening efficiency, small vibrating noises, firm and durable construction, convenient maintenance and safe operation. Specification:

| Model | Screen Deck | Screen Area | Screen Size (mm) | Screen Specifications (mm) | Max. Feed Edge (mm) | Processing Capacity (t/h) | Vibration Frequency (r/min) | Double Amplitude (mm) | Motor Power (kw) | Weight (t) | Overall Dimension (L×W×H) (mm) |

| 2YA1230 | 2 | 3.70 | 3-50 | 1220×3050 | 200 | 10-90 | 800-970 | 8 | 5.5 | 2.34 | 3502×2127×1868 |

| 3YA1230 | 3 | 3.70 | 3-80 | 1220×3050 | 200 | 30-90 | 800-970 | 8 | 7.5 | 3.05 | 3538×2168×2245 |

| 2YA1542 | 2 | 6.10 | 5-50 | 1500×4200 | 200 | 50-180 | 970 | 8 | 15 | 5.33 | 5081×2573×2660 |

| 2YA1548 | 2 | 7.10 | 5-50 | 1500×4800 | 200 | 50-190 | 970 | 8 | 15 | 5.50 | 5745×2573×3367 |

| 3YA1548 | 3 | 7.10 | 5-50 | 1500×4800 | 200 | 50-200 | 970 | 8 | 15 | 6.08 | 5909×2573×3367 |

| 4YA1548 | 4 | 7.10 | 5-50 | 1500×4800 | 200 | 50-200 | 970 | 8 | 18.5 | 6.75 | 5909×2573×3845 |

| 3YA1848 | 3 | 8.70 | 5-80 | 1800×4800 | 200 | 50-250 | 970 | 8 | 18.5 | 6.93 | 6072×2970×3366 |

| 4YA1848 | 4 | 8.70 | 5-80 | 1800×4800 | 200 | 50-260 | 970 | 8 | 22 | 7.10 | 6072×2970×3845 |

| 2YA1860 | 2 | 10.8 | 5-80 | 1800×6000 | 200 | 50-280 | 970 | 8 | 18.5 | 7.20 | 6965×2971×3276 |

| 3YA1860 | 3 | 10.8 | 5-80 | 1800×6000 | 200 | 50-300 | 970 | 8 | 18.5 | 7.70 | 7129×2971×3744 |

| 4YK1860 | 4 | 10.8 | 5-100 | 1800×6000 | 400 | 80-320 | 850 | 8 | 22 | 8.2 | 6417×3439×4276 |

| 2YK2160 | 2 | 12.8 | 5-80 | 2100×6000 | 400 | 100-330 | 850 | 8 | 30 | 7.5 | 7005×3470×3654 |

| 3YK2160 | 3 | 12.8 | 5-100 | 2100×6000 | 400 | 100-380 | 850 | 8 | 45 | 8.2 | 7172×3528×4133 |

| 4YK2160 | 4 | 12.8 | 5-150 | 2100×6000 | 400 | 120-430 | 850 | 8 | 45 | 10.3 | 7326×3545×4523 |

| 2YK2460 | 2 | 14.4 | 5-150 | 2400×6000 | 400 | 100-380 | 850 | 8 | 37 | 8.5 | 7010×3796×3654 |

| 3YK2460 | 3 | 14.4 | 5-150 | 2400×6000 | 400 | 160-450 | 850 | 8 | 45 | 9.2 | 7176×3816×4133 |

| 4YK2460 | 4 | 14.4 | 5-150 | 2400×6000 | 400 | 160-450 | 850 | 8 | 55 | 12 | 7328×3896×4523 |

| 2YK3070 | 2 | 21 | 5-150 | 3000×7000 | 400 | 150-600 | 850 | 8 | 18.5×2 | 16 | 7970×4465×4764 |

| 3YK3070 | 3 | 21 | 5-150 | 3000×7200 | 400 | 150-650 | 850 | 8 | 22×2 | 17 | 8225×4582×4822 |

Chemicals, Mine, Coal, Granite, Rock, Stone, Marble, Griotte, Calcium Carbonate, Domolite, Limestone, Limerock, Calcareous Stone, Conquina, Siliceous Limestone, Chromite Ore, Mineral, Cement, Concrete, Compound, Cobblestone, Iron Ore, Ironstone, Iron-mineral soils, Copper Ore, Azurite, Copper Sulphide Ore, Quartz Stone, Quartzite, Keli Stone, Silestone, Coal, Gold Ore, Basalt, Whinstone, Shaly, Shale, Mudstone, Nonferrous Metals Ore, etc.

RANGE OF APPLICATIONS: Sand Making Plant, Construction Waste Recycling, Household Waste Processing, Labratory, Quarry, Road, Building, Cement Plant, Building, Highway, Chemical, Metallurge, Coal Mine, Gold Mine, Benification, Mineral Separation, Stone Production, Brick Making, Ore Dressing, etc. ------------------------------------------------------------------------------------------------------------------------------------------- Spareparts Show

OUR MAIN PRODUCTS

OUR MAIN PRODUCTS

ABOUT US

ABOUT US

Why Choose Us?

Why Choose Us? 1. We are Manufacturer (Our Spare Parts Factory is one of the biggest in China): We have complete production line for both spare parts and equipment. All products are made by ourselves, with competitive price, good quality and 7*24 after service plus technical support. 2. Training & Service: 1.We provide you with the pre-installtion scheme plan, process flow design and manufacturing as per your request. 2.Send technicians to the jobsite for installation guidance and adjustment, training operators if you need. 3.Have stock for regular spare parts and machineries, which means the delivety takes shorter time. 3. If you are new in this business: We can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments. 4. We’d be glad to recommend suitable machine for you with best price. So please try to give us more information about your requirement, such as: ♦ What is the type and size of raw material? ♦ What is required size of final product(mm)? ♦ What is production capacity you want?

Supplier Information

Shanghai Shanai Machinery Co., Ltd.

[ Shanghai China ]

- Business Type : Manufacturer , Trade Company

- Product/Service : Jaw Crusher , Cone Crusher , Vertical Shaft Impact Crusher

- Tel : 15902119271

More > Other products from this company