Hebei Ruifuxiang Machinery Manufacturing Co., Ltd.

- Model No.: UN100-150

- Packaging: automatic bandsaw blade welding machine wooden case or as your request

- Delivery Time: 15 Days

- Place of Origin: Hebei, China (Mainland)

- Brand: RFX

Product Description I. UN100-150 automatic bandsaw blade welding machine

1. saw blade welding width: 20-200mm 2. Voltage transformer 3.Thickness of saw blade: <1.0mm 4.Overall size:150*90-43mm 5. Package: wooden case or as your request

Item | UN100 |

Primary voltage | 380V |

Rated Capacity | 100 KVA |

Rated input current security | 100A |

Elementary load current | <20A |

Secondary Load Current | 307-7.04V |

Secondary adjustment grade | 8 |

Duty cycle | 30 % |

Blade width | 20-150 mm |

Blade thickness | 0.6-1.65 mm |

Maximum power stroke | 60mm |

Weight | 300kgs |

automatic bandsaw blade welding machine details

automatic bandsaw blade welding machine details  automatic bandsaw blade welding machine welding details

automatic bandsaw blade welding machine welding details

automatic bandsaw blade welding machine in stock

automatic bandsaw blade welding machine in stock  Packaging & Shipping automatic bandsaw blade welding machine package

Packaging & Shipping automatic bandsaw blade welding machine package  Auxiliary machinery

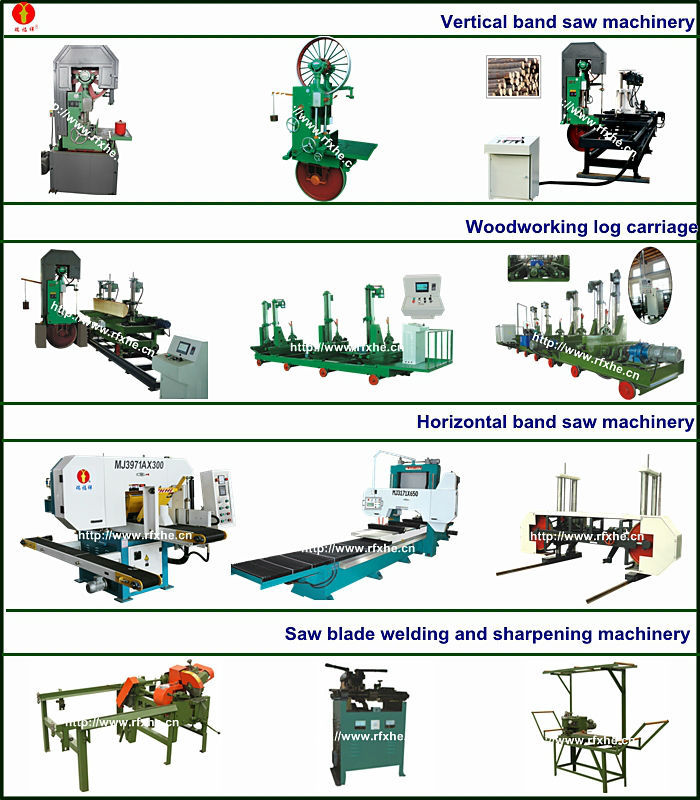

Auxiliary machinery | Woodworking band saw machinery auxiliary usually related with the saw blades. |

| Mainly the following auxiliaries: |

| 1.Saw blade grinding machinery: grinding to a certain radian,for a better cooperation of the saw wheel and saw blades. |

| 2.Saw blade sharpening machine: sharpen the saw blade tooth shape . |

| 3.Saw blade welding machine: welding the blades together after breakage. |

| For the carbided saw blades,there are another specialized machine for it : |

| 1.Carbided saw blade tooth welding machine |

| 2.Carbided saw blade tooth sharpening after welding |

| These two machine is mainly developped of the carbided saw blades,esp for cutting hardwood. save labor and time while working. |

| New pattened products: the automatic swagging and sharpening all in one machine! |

Warranty Warranty 1.1 year of guarantee for the band saw machine machinery 2. The man-made damage is beyond the guarantee 3.The small spare pars in exclusive from the guarantee

Warranty Warranty 1.1 year of guarantee for the band saw machine machinery 2. The man-made damage is beyond the guarantee 3.The small spare pars in exclusive from the guarantee Company Information

| Company information |

| 1. Over 100 workers in factory |

| 2.ISO9001-2008 quality control |

| 3.Over 10 enginer for R&D |

| 4.Member of China Forestry Machinery Association |

| 5.Multinomial product patent |

| 6.10th Year Golden supplier on Alibaba (China) |

| 7.20 years professional quality guarantee |

| 8.Leading sales in woodworking band saw national wide |

| 9.Well known brand enterprise in Hebei,China. |

saw blade welding machine company hornor

saw blade welding machine company hornor  saw blade welding machine workers

saw blade welding machine workers  saw blade welding machine workshop

saw blade welding machine workshop  Our Services

Our Services | SERVICES |

| We not only sell but we care |

| Customer Service |

| If you need any services of your bandsaw machine, please contact our Services Center. Our experienced Technician will provide fast and efficient services. |

| Tele-Service |

| Our tele-service will help you to quickly solve the machine problem by minimal repair times and lower service costs. |

| Tel: +86 319 7585460 86 311 67266073 |

| On-Site Services |

| Site service attend by qualified Technicians. |

| Spare Parts Service |

| We provide reliable spare parts and fast availability of spare parts. |

1.Why the blade always broke ?How to solve this problem ? |

| 0.1 Bad quality of the saw blades. 0.2Saw blade thickness is not matched with the machine,too thick. 0.3Breakage of the bearings.Shows like the big noise of the band saw, the vibrating of the blades while cutting or blades running off. 0.4Long time of blades using.Blades tiresomeness and blunting, with the beating of the wood and broke. 0.5 Too much rolling of the blades,lost the blades stretch . 0.6Back part of the blade uneven.while working,the blades will comes front and back, then the stressed parts broke. 0.7 Loss of the cold water while cutting.Without the cold water, the higher temperature brings the tiresomeness of the blades,then broke. |

2.How to solve this breakage of the saw blades? |

| 0.1 Loss the tightness of the blades 0.2 Choose a thinner saw blades 0.3 Professional workers grinding the blades 0.4 Professional workers rounding the wheel or change the bearings. |

3.How to weld the broken saw blades? |

| 0.1 The breakage with 2cm,use the small tool pound on the blade from both sides, and then use the small hummer make it flat. 0.2 The breakage above 2mm,use the welding machinery welds them together. And then fixed the surface smooth for working. |

- Business Type : Manufacturer , Trade Company

- Product/Service : Woodworking Band Saw , Woodworking Log Carriage , Auxiliary Machinery

- Tel : 86-311-67266073