Hebei Ruifuxiang Machinery Manufacturing Co., Ltd.

- Model No.: MJ318

- Packaging: vertical sawmill planks cutting machine Nude packing or as your request

- Delivery Time: 30 Days

- Place of Origin: Hebei, China (Mainland)

- Brand: RFX

III. Main structure of the MJ318 vertical sawmill planks cutting machine

III. Main structure of the MJ318 vertical sawmill planks cutting machine  Note :this band saw should work together with the carriage vehicle . IV.Specification of MJ318 vertical sawmill planks cutting machine

Note :this band saw should work together with the carriage vehicle . IV.Specification of MJ318 vertical sawmill planks cutting machine Model | MJ318wood working vertical band saw machine | |

| Main body | Saw wheel diameter | 800mm |

Overall size | 1040*800*1900mm | |

Rotary speed of saw wheel | 750r/min | |

Motor power/Voltage frequency | 7.5kw / 380V 50Hz | |

Weight of machine | 780 kgs | |

| Saw blade | Thickness | 0.9mm |

Width | 100mm | |

Length | 5700mm | |

| Wood suited | Max. saw blade length | 6400mm |

vertical sawmill planks cutting machine Main body

vertical sawmill planks cutting machine Main body  vertical sawmill planks cutting machine Assembling

vertical sawmill planks cutting machine Assembling  vertical sawmill planks cutting machine in stock for your reference

vertical sawmill planks cutting machine in stock for your reference | Packing |

| Nude packing or with the plastic film outside |

| Shipping |

| Usually the band saw together with the log carriage |

| 1 full set for 1*20ft container |

| Also can have room for the sharpening and grinding machine etc. |

vertical sawmill planks cutting machine shipping

vertical sawmill planks cutting machine shipping  vertical sawmill planks cutting machine labels for your reference

vertical sawmill planks cutting machine labels for your reference  Accessories Woodworking band saw machinery auxiliary usually related with the saw blades. Mainly the following auxiliaries: 1.Saw blade grinding machinery: grinding to a certain radian,for a better cooperation of the saw wheel and saw blades. 2.Saw blade sharpening machine: sharpen the saw blade tooth shape . 3.Saw blade welding machine: welding the blades together after breakage. For the carbided saw blades,there are another specialized machine for it : 1.Carbided saw blade tooth welding machine 2.Carbided saw blade tooth sharpening after welding These two machine is mainly developped of the carbided saw blades,esp for cutting hardwood.save labor and time while working. New pattened products: the automatic swagging and sharpening all in one machine!

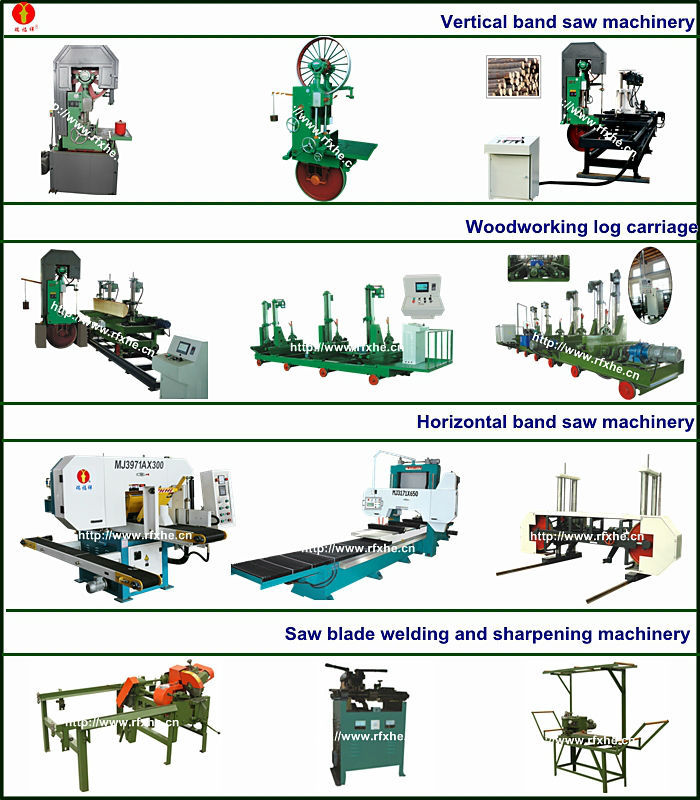

Accessories Woodworking band saw machinery auxiliary usually related with the saw blades. Mainly the following auxiliaries: 1.Saw blade grinding machinery: grinding to a certain radian,for a better cooperation of the saw wheel and saw blades. 2.Saw blade sharpening machine: sharpen the saw blade tooth shape . 3.Saw blade welding machine: welding the blades together after breakage. For the carbided saw blades,there are another specialized machine for it : 1.Carbided saw blade tooth welding machine 2.Carbided saw blade tooth sharpening after welding These two machine is mainly developped of the carbided saw blades,esp for cutting hardwood.save labor and time while working. New pattened products: the automatic swagging and sharpening all in one machine!  Related Products

Related Products  Company Information Hebei Ruifuxiang Machinery Manfacturing Co.,ltd is specialized in the woodworking bandsaw manufacturing.Strong in technology and excellent in equipment. Uninterrupted research and development of new products is our permanent pursuit.

Company Information Hebei Ruifuxiang Machinery Manfacturing Co.,ltd is specialized in the woodworking bandsaw manufacturing.Strong in technology and excellent in equipment. Uninterrupted research and development of new products is our permanent pursuit. | Company information |

| 1. Over 100 workers in factory |

| 2.ISO9001-2008 quality control |

| 3.Over 10 enginer for R&D |

| 4.Member of China Forestry Machinery Association |

| 5.Multinomial product patent |

| 6.10th Year Golden supplier on Alibaba (China) |

| 7.20 years professional quality guarantee |

| 8.Leading sales in woodworking band saw national wide |

| 9.Well known brand enterprise in Hebei,China. |

Our vertical sawmill planks cutting machine workshop

Our vertical sawmill planks cutting machine workshop  Our Services

Our Services | SERVICES |

| We not only sell but we care |

| Customer Service |

| If you need any services of your bandsaw machine, please contact our Services Center. Our experienced Technician will provide fast and efficient services. |

| Tele-Service |

| Our tele-service will help you to quickly solve the machine problem by minimal repair times and lower service costs. |

| Tel: +86 319 7585460 86 311 67266073 |

| On-Site Services |

| Site service attend by qualified Technicians. |

| Spare Parts Service |

| We provide reliable spare parts and fast availability of spare parts. |

| FAQ |

| 1.How to choose a suitale band saw ? |

| 0.1 wood hardness-----band saw main body material 0.2 wood max diameter------band saw model 0.3 wood max length --------band saw log carriage length |

| 2.how many typs of band saw do you have |

| 0.1 vertical table band saw for planks 0.2 vertical band saw with log carriage for raw logs 0.3 Horizontal band saw for raw logs |

| 3.How to choose a log carriage |

| 0.1 wood max diameter-----band saw and log carriage model 0.2 wood max length --------log carriage length 0.3 automatic degree-----manual,semi-auto or fully auto 0.4 output request -------automatic degre |

| 4.How many types of the log carriage do you have? |

| 0.1 manual one ----walking and feeding all manual 0.2 semi-auto one----walking or feeding auto 0.3 fully auto one------walking ,feeding and wood clamping auto a. normal track-----portable auto log carriage b.linear guide track ----------portable auto log cariage |

| 5.How about the working range for the band saw machine? |

| For vertical band saw,max wood diameter sawed to 1500mm, and min cutting thickness to 2.0mm. For horizontal band saw,max wood diameter sawed to 2500mm, min cutting thickness to 1.5mm. |

| 6.How about the band saw feeding speed ? |

| The feeding speed is related with the raw logs diameter,wood types etc. For the usual wood,vertical band saw feeding speed can reach to 30-60m/min while horizontal band saw feeding speed to 15m/min. |

| 7.What’s the kerf? How about the min kerf the band saw can reach ? |

| The kerf mains the slit or notch made by a saw or cutting torch. The kerf size is related with the wood type,saw blade thickness and the swagging etc. Usually for alloy saw blade,the kerf is 1.7mm while the normal is 3mm. |

- Business Type : Manufacturer , Trade Company

- Product/Service : Woodworking Band Saw , Woodworking Log Carriage , Auxiliary Machinery

- Tel : 86-311-67266073