Hebei Ruifuxiang Machinery Manufacturing Co., Ltd.

- Model No.: MJ3212

- Packaging: electrical timber band saw Nude packing or as your request

- Delivery Time: 30 Days

- Place of Origin: Hebei, China (Mainland)

- Brand: RFX

Note :this band saw should work together with the carriage vehicle. IV.Specification of MJ3212 electrical timber band saw

Note :this band saw should work together with the carriage vehicle. IV.Specification of MJ3212 electrical timber band saw Model | RFX MJ3212 vertical band saw machine for woodworking | |

Main body | Saw wheel diameter | 1250mm |

Overall size | 1400*1440*2600mm | |

Rotary speed of saw wheel | 650r/min | |

Motor power/Voltage frequency | 37 kw / 380V 50Hz | |

Weight of machine | 2800kg | |

Saw blade | Thickness | 1.25mm |

Width | 150mm | |

Length | 8300mm | |

Wood suited | Max cutting log diameter | 1000mm |

Hardness | medium-hard wood | |

Shield | We can supply shield if you need | |

Auxiliary machine------the log carriage vehicle

Auxiliary machine------the log carriage vehicle Carriage model | PCHZ5000 casting automatic | PCHZ5000 Weldment automatic |

Number of stakes clips | 4 sets | 4 sets |

Number of wheels | 2 sets | 2 sets |

Walking(forward, back) | Automatic | Automatic |

Card wood | Automatically card wood | Automatically card wood |

Max. Log diam | 800mm | 800mm |

Length of log | 6000mm | 6000mm |

Length of track | 5000mm | 5000mm |

2. electrical timber band saw in stock for your reference

2. electrical timber band saw in stock for your reference  Advantages

Advantages | Rugged construction to withstand rough loads and stand for longer life. |

| Designed all standardized parts. |

| Designed and produced to fulfill customers' entire satisfaction. |

| Main body | Rugged construction to withstand rough loads and stand for longer life. Designed all standardized parts. Designed and produced to fulfill customers' entire satisfaction. |

| Flywheel | Extra thickness steel rims made top wheel with supporting spokes Casting iron /casting steel buttom wheel longer life High qualified taper roller bearings with adjustablelock nuts. Fully balanced for smooth running |

Packaging & Shipping

Packaging & Shipping | Packing |

| Nude packing or with the plastic film outside |

| Shipping |

| Usually the band saw together with the log carriage |

| 1 full set for 1*20ft container |

| Also can have room for the sharpening and grinding machine etc. |

4. electrical timber band saw Loading pictures for your reference

4. electrical timber band saw Loading pictures for your reference  Accessories Woodworking band saw machinery auxiliary usually related with the saw blades. Mainly the following auxiliaries: 1.Saw blade grinding machinery: grinding to a certain radian,for a better cooperation of the saw wheel and saw blades. 2.Saw blade sharpening machine: sharpen the saw blade tooth shape . 3.Saw blade welding machine: welding the blades together after breakage. For the carbided saw blades,there are another specialized machine for it : 1.Carbided saw blade tooth welding machine 2.Carbided saw blade tooth sharpening after welding These two machine is mainly developped of the carbided saw blades,esp for cutting hardwood.save labor and time while working. New pattened products: the automatic swagging and sharpening all in one machine!

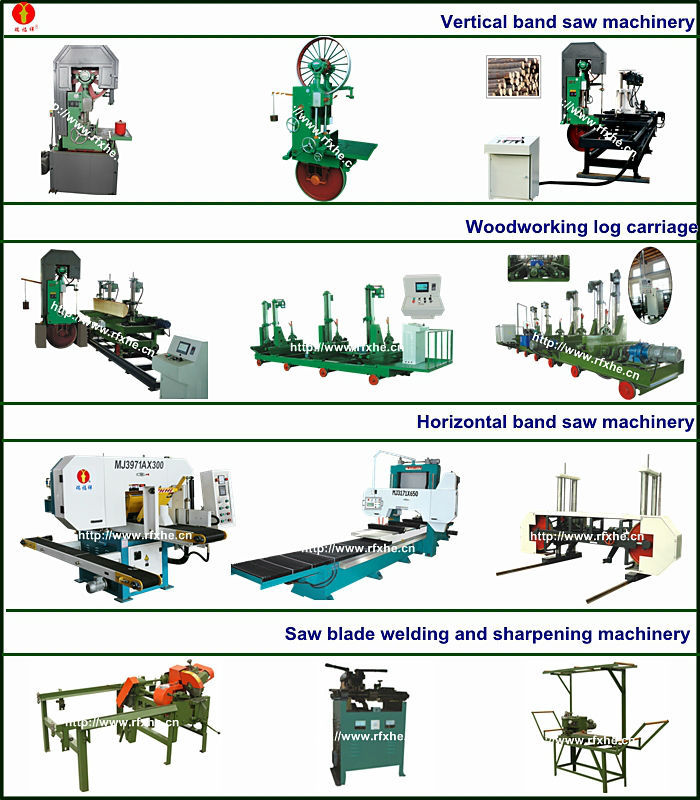

Accessories Woodworking band saw machinery auxiliary usually related with the saw blades. Mainly the following auxiliaries: 1.Saw blade grinding machinery: grinding to a certain radian,for a better cooperation of the saw wheel and saw blades. 2.Saw blade sharpening machine: sharpen the saw blade tooth shape . 3.Saw blade welding machine: welding the blades together after breakage. For the carbided saw blades,there are another specialized machine for it : 1.Carbided saw blade tooth welding machine 2.Carbided saw blade tooth sharpening after welding These two machine is mainly developped of the carbided saw blades,esp for cutting hardwood.save labor and time while working. New pattened products: the automatic swagging and sharpening all in one machine!  Related Products

Related Products  6. electrical timber band saw Factory for your reference

6. electrical timber band saw Factory for your reference  Our Services

Our Services | SERVICES |

| We not only sell but we care |

| Customer Service |

| If you need any services of your bandsaw machine, please contact our Services Center. Our experienced Technician will provide fast and efficient services. |

| Tele-Service |

| Our tele-service will help you to quickly solve the machine problem by minimal repair times and lower service costs. |

| Tel: +86 319 7585460 86 311 67266073 |

| On-Site Services |

| Site service attend by qualified Technicians. |

| Spare Parts Service |

| We provide reliable spare parts and fast availability of spare parts. |

- Business Type : Manufacturer , Trade Company

- Product/Service : Woodworking Band Saw , Woodworking Log Carriage , Auxiliary Machinery

- Tel : 86-311-67266073