Beijing Dingtek Technology Corp.,Ltd

Basic Information

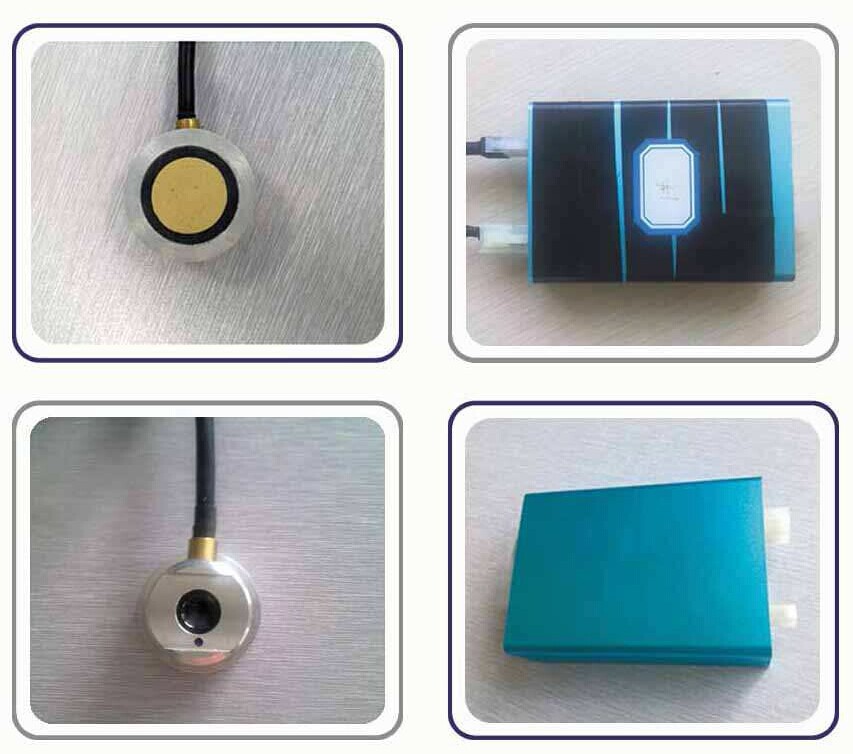

- Model No.: F500 Ultrasonic packing sensor

- Packaging: Ultrasonic packing sensor standard package

- Delivery Time: 1 Days

- Place of Origin: Beijing, China (Mainland)

- Brand: Ultrasonic packing sensor

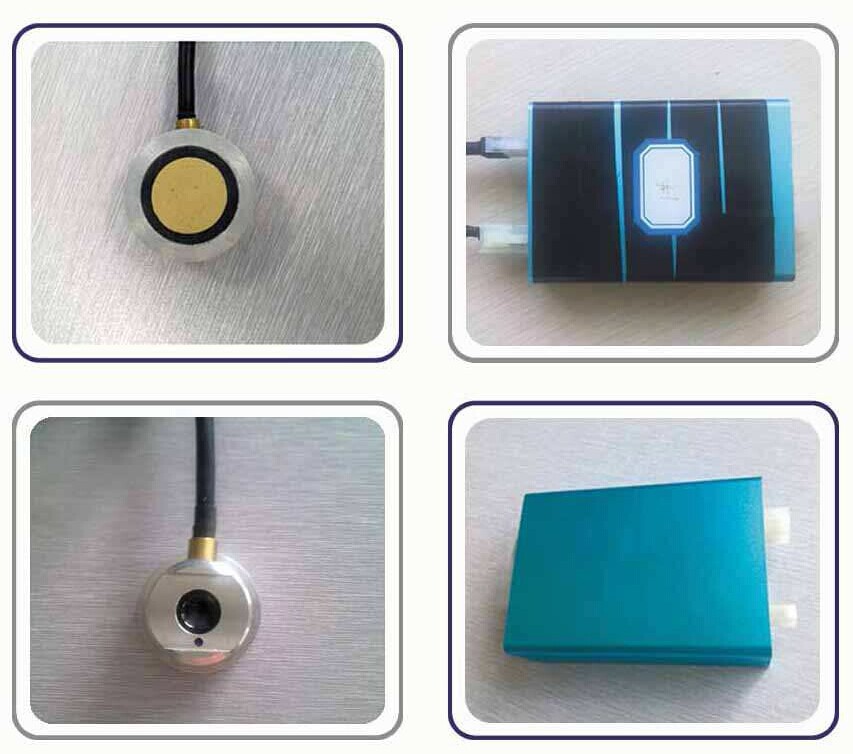

F500 New 2015 one of most popular Easily install Ultrasonic packing sensor Product Description Overview F500 is ultrasonic fuel level sensor which do not need to drill on tank and just fix it on the tank to get fuel level of the tank. No need to drill on fuel tank. Easily install. The following parts are included in package: 1* sensor head with wire to convertor box 1* convertor box

1* 2 pin power wire for convert box (Red and Black)

1* 4 pin wire for output signal (Yellow, Green, Blue,Black)

1* glue (cyanoacrylate adhesive)

Notes: As the ship rules by express, maybe glue is not accepted, So if there is no glue in package, user need to find the similar product on local market.

Specification 1.Measurement length:30~ 800mm 2.Resolution:1mm 3.Power Supply:10-33V DC 4.Output Signal:0-6V DC, RS232 5.Explosion Proof:Exia Ⅱ CT6 6.Working Temperature:-40 ~ 85℃ 7.Media:diesel, biodiesel, gasoline and etc 8.Protection Rank:IP66 9.Mounting:Glue fixing Features

Specification 1.Measurement length:30~ 800mm 2.Resolution:1mm 3.Power Supply:10-33V DC 4.Output Signal:0-6V DC, RS232 5.Explosion Proof:Exia Ⅱ CT6 6.Working Temperature:-40 ~ 85℃ 7.Media:diesel, biodiesel, gasoline and etc 8.Protection Rank:IP66 9.Mounting:Glue fixing Features

1.Non-touch measurement;

2.Easily install, no need to drill on tank;

3.Measurement length can be adjusted to 3 meters;

4.Interface for gps or gprs modem using. Application This Ultrasonic fuel level sensor Ultrasonic fuel level sensor has a wide range of application,it can be used for all kinds of liquid,such as water,oil,car using gasoline,diesel,biodiesel,and also can be used for solid,such as cement level sensor, it can be applied to many different places,such as small tanks,atmospheric tanks,process tanks,small container,pump station,wastewater tanks,etc. Installation Preparation before Installation Please prepare items below:

Installation Preparation before Installation Please prepare items below:

1. ultrasonic sensor standard package,

2.ultrasonic couplant (the thing to be media of sensor head and target object, if no such thing,

water is also ok),

3. Glue (maybe in the standard package, if not, please get from local market)

4. fix band,

5. voltage meter,

6. screw tool,

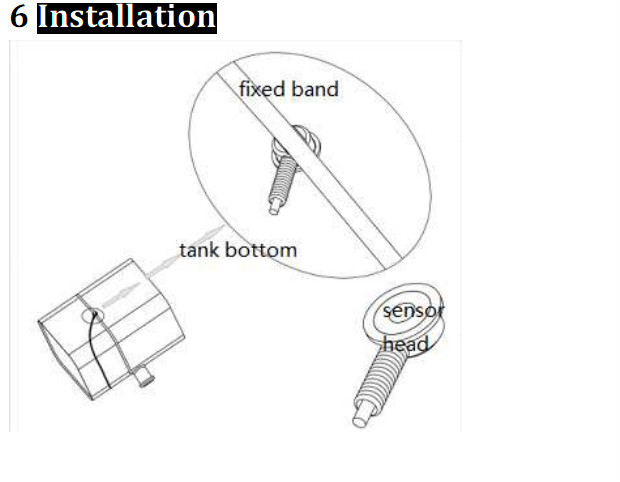

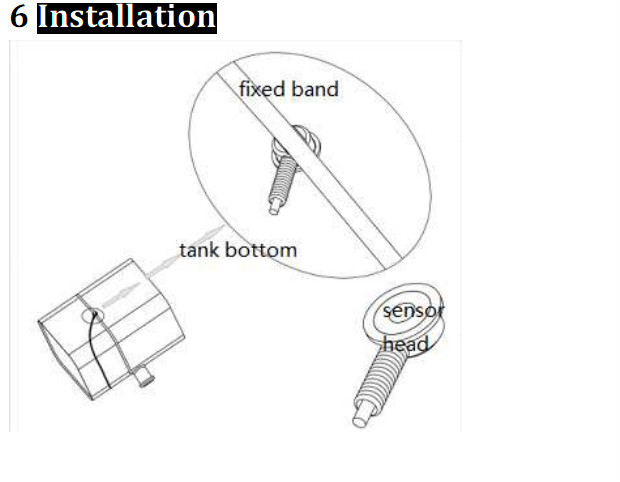

7. abrasive paper. Installation of Sensor Head and Box 1.Vehicle, tank and fluid. Before installation, the vehicle need stop and on flat ground. The fuel tank or container need to be vertical to the ground. Furthermore, there is should flat area on the bottom of the tank(container) in order to fix the sensor head. The fluid in the tank should no less than 1/4 total volume. 2.Cleaning. Select one flat area on bottom of the tank (container),clean the dirt on the flat area to make it smooth. If paint cover on the steel tank, please us the abrasive paper to remove the paint cover. After cleaning, there is no any part between the sensor head and the bottom shell of the tank(container). 3.Measure output. Put couplant (or water, if air temperature is less than zero, please use lubricant) on the sensor head (the detecting slide), and make the sensor head detecting slide contact the cleaning area without air between them. Power on the convertor box, measure the output value of the sensor. If it is stable and value is 0.1~6.0v, then this position is good selection. Otherwise,change another position to repeat the cleaning and measurement. 4.Fix sensor head. Cleaning the couplant or water or lubricate on the sensor head, and the tank flat area. Put glue on the sensor head and fix the sensor head on the flat area (not too big pressure,just make them contact without air), wait for several minutes to wait for the glue freeze. During the waiting time, measure the output of value, if not stable, split the sensor head with the tank (container), and repeat this step. But make sure not break the

1.Vehicle, tank and fluid. Before installation, the vehicle need stop and on flat ground. The fuel tank or container need to be vertical to the ground. Furthermore, there is should flat area on the bottom of the tank(container) in order to fix the sensor head. The fluid in the tank should no less than 1/4 total volume. 2.Cleaning. Select one flat area on bottom of the tank (container),clean the dirt on the flat area to make it smooth. If paint cover on the steel tank, please us the abrasive paper to remove the paint cover. After cleaning, there is no any part between the sensor head and the bottom shell of the tank(container). 3.Measure output. Put couplant (or water, if air temperature is less than zero, please use lubricant) on the sensor head (the detecting slide), and make the sensor head detecting slide contact the cleaning area without air between them. Power on the convertor box, measure the output value of the sensor. If it is stable and value is 0.1~6.0v, then this position is good selection. Otherwise,change another position to repeat the cleaning and measurement. 4.Fix sensor head. Cleaning the couplant or water or lubricate on the sensor head, and the tank flat area. Put glue on the sensor head and fix the sensor head on the flat area (not too big pressure,just make them contact without air), wait for several minutes to wait for the glue freeze. During the waiting time, measure the output of value, if not stable, split the sensor head with the tank (container), and repeat this step. But make sure not break the

sensor head. 5.Use fine sandpaper, wet cloth to clean up the dirt sensor is installed probes, sand. 6.Serial or voltage analog cable, connect the GND cable out of Terminal, such as the GSM/GPS module. 7.Sensor probes and effectively apply a layer of glue, and when you put it on the bottom of the fuel tank sensor probe, requires a layer of water between the fuel tank and sensor probe. If temperatures below 0 degrees, lubricant can be used instead of water, tested after the degreasing method of clean lubricant. 8.Convertor box mounted in the cab-friendly location. The line for sensor head can be extend by user. But no more than 15 meters. 9.Connect the wire and fix the wire on vehicle. For the output signal,just connect to the device of user. Our Ultrasonic fuel level sensor can accurately measure for you the volume of the liquid.Please refer to the following diagram.

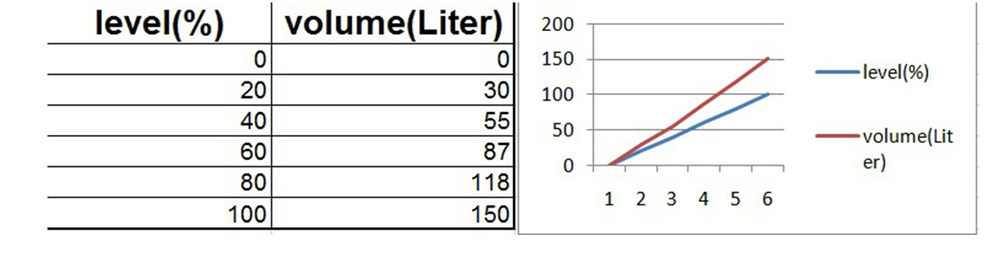

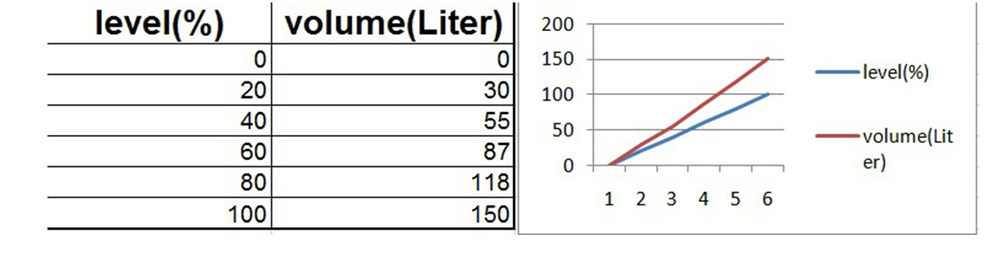

Our Ultrasonic fuel level sensor can accurately measure for you the volume of the liquid.Please refer to the following diagram.

The following diagram shows the comsumption of fuel with its speed,for fuel level monitoring.This Ultrasonic fuel level sensor can be used together with vehicle gps tracker.

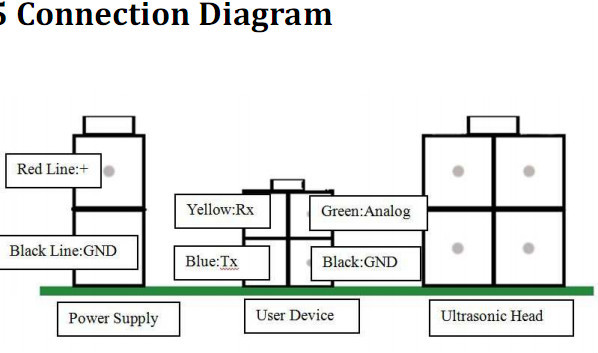

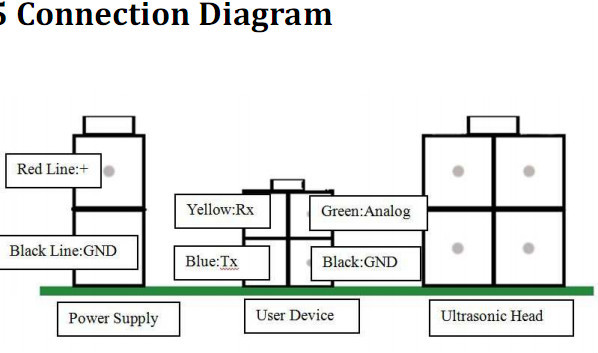

The following diagram shows the comsumption of fuel with its speed,for fuel level monitoring.This Ultrasonic fuel level sensor can be used together with vehicle gps tracker.  After installation,I believe the most important step you want to know is how to monitor the fuel level change? as this is an ultrasonic level sensor with analog output,the output voltage is 0-5v,so you can monitor the change of oil level through the change of voltage by a meter,and there is RS232 com,so you can also use it with vehicle gps tracker. The following is a wire connection diagram,you can connect the wire of the sensor with the wire of your meter or gps device as the picture shows below.

After installation,I believe the most important step you want to know is how to monitor the fuel level change? as this is an ultrasonic level sensor with analog output,the output voltage is 0-5v,so you can monitor the change of oil level through the change of voltage by a meter,and there is RS232 com,so you can also use it with vehicle gps tracker. The following is a wire connection diagram,you can connect the wire of the sensor with the wire of your meter or gps device as the picture shows below.  If you have any other questions of our gps fuel level sensor,please feel free to contact me,I'm glad to help you:) Our Services Packaging & Shipping For this Ultrasonic fuel level sensor ,we provide standard,strong,protective shipping package to prevent it from outer damage,we also accept package required.

If you have any other questions of our gps fuel level sensor,please feel free to contact me,I'm glad to help you:) Our Services Packaging & Shipping For this Ultrasonic fuel level sensor ,we provide standard,strong,protective shipping package to prevent it from outer damage,we also accept package required.  We provide many kinds of economic and express shipping method for your selection.

We provide many kinds of economic and express shipping method for your selection.  Company Information We are Beijing Dingtek Technical Co.,Ltd.We especially engaged in personal gps tracker,vehicle/automotive gps tracker,liquid level sensors,industrial all in one pc.We have been in this line for many years.We provide competitive quality products and powerful customer service,and has receive high reputation from customers all over the world. Welcome to contact us for cooperation. Ultrasonic fuel level sensor Warranty Ultrasonic fuel level sensor We warrants this quality product to be free of defects in material and workmanship for a period of one year from the date of purchase. During the period, we will repair or replace the product at no charge for parts or labor. But the shipment fee will be shared by the buyer (one party 50%). TIME PERIOD OF THIS WARRANTY The time period of this warranty starts from the date of the original purchase and expires on the first anniversary date of purchase. WHAT IS NOT COVERED BY THIS WARRANTY No express or implied warranty is made for any defects in this product which result from accident, abuse, misuse, failure to operate the product in accordance with relevant instructions, neglect, immersion in or exposure to chemicals or liquids, extremes of climate, fungus, excessive wear and tear/cosmetic damage and defects resulting from other extraneous causes such as unauthorised disassembly, repair or modification. This warranty shall not extend to any incidental or consequential damages arising from the purchase, use or inability to use this product even if Vivitar has been advised of such damages. The laws of some countries and some States thereof do not allow the limitation of incidental or consequential damages, so the above limitation or exclusion may apply to you. FAQ 1.the most appropriate thick of tank wall ? ≤1cm 2.where is the best place for installation ? The bottom of tank . 3.how to test ? When you testing , notice no air between the tank and the probe .and sure the tank is smooth . 4.how to connect RS232/458 output ? Put the blue & yellow & black line together . 5.how to connect analog 0-5V output ? Put the green & black line together . F500 New 2015 one of most popular Easily install Ultrasonic packing sensor

Company Information We are Beijing Dingtek Technical Co.,Ltd.We especially engaged in personal gps tracker,vehicle/automotive gps tracker,liquid level sensors,industrial all in one pc.We have been in this line for many years.We provide competitive quality products and powerful customer service,and has receive high reputation from customers all over the world. Welcome to contact us for cooperation. Ultrasonic fuel level sensor Warranty Ultrasonic fuel level sensor We warrants this quality product to be free of defects in material and workmanship for a period of one year from the date of purchase. During the period, we will repair or replace the product at no charge for parts or labor. But the shipment fee will be shared by the buyer (one party 50%). TIME PERIOD OF THIS WARRANTY The time period of this warranty starts from the date of the original purchase and expires on the first anniversary date of purchase. WHAT IS NOT COVERED BY THIS WARRANTY No express or implied warranty is made for any defects in this product which result from accident, abuse, misuse, failure to operate the product in accordance with relevant instructions, neglect, immersion in or exposure to chemicals or liquids, extremes of climate, fungus, excessive wear and tear/cosmetic damage and defects resulting from other extraneous causes such as unauthorised disassembly, repair or modification. This warranty shall not extend to any incidental or consequential damages arising from the purchase, use or inability to use this product even if Vivitar has been advised of such damages. The laws of some countries and some States thereof do not allow the limitation of incidental or consequential damages, so the above limitation or exclusion may apply to you. FAQ 1.the most appropriate thick of tank wall ? ≤1cm 2.where is the best place for installation ? The bottom of tank . 3.how to test ? When you testing , notice no air between the tank and the probe .and sure the tank is smooth . 4.how to connect RS232/458 output ? Put the blue & yellow & black line together . 5.how to connect analog 0-5V output ? Put the green & black line together . F500 New 2015 one of most popular Easily install Ultrasonic packing sensor

1* 2 pin power wire for convert box (Red and Black)

1* 4 pin wire for output signal (Yellow, Green, Blue,Black)

1* glue (cyanoacrylate adhesive)

Notes: As the ship rules by express, maybe glue is not accepted, So if there is no glue in package, user need to find the similar product on local market.

Specification 1.Measurement length:30~ 800mm 2.Resolution:1mm 3.Power Supply:10-33V DC 4.Output Signal:0-6V DC, RS232 5.Explosion Proof:Exia Ⅱ CT6 6.Working Temperature:-40 ~ 85℃ 7.Media:diesel, biodiesel, gasoline and etc 8.Protection Rank:IP66 9.Mounting:Glue fixing Features

Specification 1.Measurement length:30~ 800mm 2.Resolution:1mm 3.Power Supply:10-33V DC 4.Output Signal:0-6V DC, RS232 5.Explosion Proof:Exia Ⅱ CT6 6.Working Temperature:-40 ~ 85℃ 7.Media:diesel, biodiesel, gasoline and etc 8.Protection Rank:IP66 9.Mounting:Glue fixing Features1.Non-touch measurement;

2.Easily install, no need to drill on tank;

3.Measurement length can be adjusted to 3 meters;

4.Interface for gps or gprs modem using. Application This Ultrasonic fuel level sensor Ultrasonic fuel level sensor has a wide range of application,it can be used for all kinds of liquid,such as water,oil,car using gasoline,diesel,biodiesel,and also can be used for solid,such as cement level sensor, it can be applied to many different places,such as small tanks,atmospheric tanks,process tanks,small container,pump station,wastewater tanks,etc.

Installation Preparation before Installation Please prepare items below:

Installation Preparation before Installation Please prepare items below:1. ultrasonic sensor standard package,

2.ultrasonic couplant (the thing to be media of sensor head and target object, if no such thing,

water is also ok),

3. Glue (maybe in the standard package, if not, please get from local market)

4. fix band,

5. voltage meter,

6. screw tool,

7. abrasive paper. Installation of Sensor Head and Box

1.Vehicle, tank and fluid. Before installation, the vehicle need stop and on flat ground. The fuel tank or container need to be vertical to the ground. Furthermore, there is should flat area on the bottom of the tank(container) in order to fix the sensor head. The fluid in the tank should no less than 1/4 total volume. 2.Cleaning. Select one flat area on bottom of the tank (container),clean the dirt on the flat area to make it smooth. If paint cover on the steel tank, please us the abrasive paper to remove the paint cover. After cleaning, there is no any part between the sensor head and the bottom shell of the tank(container). 3.Measure output. Put couplant (or water, if air temperature is less than zero, please use lubricant) on the sensor head (the detecting slide), and make the sensor head detecting slide contact the cleaning area without air between them. Power on the convertor box, measure the output value of the sensor. If it is stable and value is 0.1~6.0v, then this position is good selection. Otherwise,change another position to repeat the cleaning and measurement. 4.Fix sensor head. Cleaning the couplant or water or lubricate on the sensor head, and the tank flat area. Put glue on the sensor head and fix the sensor head on the flat area (not too big pressure,just make them contact without air), wait for several minutes to wait for the glue freeze. During the waiting time, measure the output of value, if not stable, split the sensor head with the tank (container), and repeat this step. But make sure not break the

1.Vehicle, tank and fluid. Before installation, the vehicle need stop and on flat ground. The fuel tank or container need to be vertical to the ground. Furthermore, there is should flat area on the bottom of the tank(container) in order to fix the sensor head. The fluid in the tank should no less than 1/4 total volume. 2.Cleaning. Select one flat area on bottom of the tank (container),clean the dirt on the flat area to make it smooth. If paint cover on the steel tank, please us the abrasive paper to remove the paint cover. After cleaning, there is no any part between the sensor head and the bottom shell of the tank(container). 3.Measure output. Put couplant (or water, if air temperature is less than zero, please use lubricant) on the sensor head (the detecting slide), and make the sensor head detecting slide contact the cleaning area without air between them. Power on the convertor box, measure the output value of the sensor. If it is stable and value is 0.1~6.0v, then this position is good selection. Otherwise,change another position to repeat the cleaning and measurement. 4.Fix sensor head. Cleaning the couplant or water or lubricate on the sensor head, and the tank flat area. Put glue on the sensor head and fix the sensor head on the flat area (not too big pressure,just make them contact without air), wait for several minutes to wait for the glue freeze. During the waiting time, measure the output of value, if not stable, split the sensor head with the tank (container), and repeat this step. But make sure not break thesensor head. 5.Use fine sandpaper, wet cloth to clean up the dirt sensor is installed probes, sand. 6.Serial or voltage analog cable, connect the GND cable out of Terminal, such as the GSM/GPS module. 7.Sensor probes and effectively apply a layer of glue, and when you put it on the bottom of the fuel tank sensor probe, requires a layer of water between the fuel tank and sensor probe. If temperatures below 0 degrees, lubricant can be used instead of water, tested after the degreasing method of clean lubricant. 8.Convertor box mounted in the cab-friendly location. The line for sensor head can be extend by user. But no more than 15 meters. 9.Connect the wire and fix the wire on vehicle. For the output signal,just connect to the device of user.

Our Ultrasonic fuel level sensor can accurately measure for you the volume of the liquid.Please refer to the following diagram.

Our Ultrasonic fuel level sensor can accurately measure for you the volume of the liquid.Please refer to the following diagram.

The following diagram shows the comsumption of fuel with its speed,for fuel level monitoring.This Ultrasonic fuel level sensor can be used together with vehicle gps tracker.

The following diagram shows the comsumption of fuel with its speed,for fuel level monitoring.This Ultrasonic fuel level sensor can be used together with vehicle gps tracker.  After installation,I believe the most important step you want to know is how to monitor the fuel level change? as this is an ultrasonic level sensor with analog output,the output voltage is 0-5v,so you can monitor the change of oil level through the change of voltage by a meter,and there is RS232 com,so you can also use it with vehicle gps tracker. The following is a wire connection diagram,you can connect the wire of the sensor with the wire of your meter or gps device as the picture shows below.

After installation,I believe the most important step you want to know is how to monitor the fuel level change? as this is an ultrasonic level sensor with analog output,the output voltage is 0-5v,so you can monitor the change of oil level through the change of voltage by a meter,and there is RS232 com,so you can also use it with vehicle gps tracker. The following is a wire connection diagram,you can connect the wire of the sensor with the wire of your meter or gps device as the picture shows below.  If you have any other questions of our gps fuel level sensor,please feel free to contact me,I'm glad to help you:) Our Services Packaging & Shipping For this Ultrasonic fuel level sensor ,we provide standard,strong,protective shipping package to prevent it from outer damage,we also accept package required.

If you have any other questions of our gps fuel level sensor,please feel free to contact me,I'm glad to help you:) Our Services Packaging & Shipping For this Ultrasonic fuel level sensor ,we provide standard,strong,protective shipping package to prevent it from outer damage,we also accept package required.  We provide many kinds of economic and express shipping method for your selection.

We provide many kinds of economic and express shipping method for your selection.  Company Information We are Beijing Dingtek Technical Co.,Ltd.We especially engaged in personal gps tracker,vehicle/automotive gps tracker,liquid level sensors,industrial all in one pc.We have been in this line for many years.We provide competitive quality products and powerful customer service,and has receive high reputation from customers all over the world. Welcome to contact us for cooperation. Ultrasonic fuel level sensor Warranty Ultrasonic fuel level sensor We warrants this quality product to be free of defects in material and workmanship for a period of one year from the date of purchase. During the period, we will repair or replace the product at no charge for parts or labor. But the shipment fee will be shared by the buyer (one party 50%). TIME PERIOD OF THIS WARRANTY The time period of this warranty starts from the date of the original purchase and expires on the first anniversary date of purchase. WHAT IS NOT COVERED BY THIS WARRANTY No express or implied warranty is made for any defects in this product which result from accident, abuse, misuse, failure to operate the product in accordance with relevant instructions, neglect, immersion in or exposure to chemicals or liquids, extremes of climate, fungus, excessive wear and tear/cosmetic damage and defects resulting from other extraneous causes such as unauthorised disassembly, repair or modification. This warranty shall not extend to any incidental or consequential damages arising from the purchase, use or inability to use this product even if Vivitar has been advised of such damages. The laws of some countries and some States thereof do not allow the limitation of incidental or consequential damages, so the above limitation or exclusion may apply to you. FAQ 1.the most appropriate thick of tank wall ? ≤1cm 2.where is the best place for installation ? The bottom of tank . 3.how to test ? When you testing , notice no air between the tank and the probe .and sure the tank is smooth . 4.how to connect RS232/458 output ? Put the blue & yellow & black line together . 5.how to connect analog 0-5V output ? Put the green & black line together . F500 New 2015 one of most popular Easily install Ultrasonic packing sensor

Company Information We are Beijing Dingtek Technical Co.,Ltd.We especially engaged in personal gps tracker,vehicle/automotive gps tracker,liquid level sensors,industrial all in one pc.We have been in this line for many years.We provide competitive quality products and powerful customer service,and has receive high reputation from customers all over the world. Welcome to contact us for cooperation. Ultrasonic fuel level sensor Warranty Ultrasonic fuel level sensor We warrants this quality product to be free of defects in material and workmanship for a period of one year from the date of purchase. During the period, we will repair or replace the product at no charge for parts or labor. But the shipment fee will be shared by the buyer (one party 50%). TIME PERIOD OF THIS WARRANTY The time period of this warranty starts from the date of the original purchase and expires on the first anniversary date of purchase. WHAT IS NOT COVERED BY THIS WARRANTY No express or implied warranty is made for any defects in this product which result from accident, abuse, misuse, failure to operate the product in accordance with relevant instructions, neglect, immersion in or exposure to chemicals or liquids, extremes of climate, fungus, excessive wear and tear/cosmetic damage and defects resulting from other extraneous causes such as unauthorised disassembly, repair or modification. This warranty shall not extend to any incidental or consequential damages arising from the purchase, use or inability to use this product even if Vivitar has been advised of such damages. The laws of some countries and some States thereof do not allow the limitation of incidental or consequential damages, so the above limitation or exclusion may apply to you. FAQ 1.the most appropriate thick of tank wall ? ≤1cm 2.where is the best place for installation ? The bottom of tank . 3.how to test ? When you testing , notice no air between the tank and the probe .and sure the tank is smooth . 4.how to connect RS232/458 output ? Put the blue & yellow & black line together . 5.how to connect analog 0-5V output ? Put the green & black line together . F500 New 2015 one of most popular Easily install Ultrasonic packing sensor

Supplier Information

Beijing Dingtek Technology Corp.,Ltd

[ Beijing China ]

- Business Type : Trade Company

- Product/Service : liquid level sensor , GPS tracker , Temperature sensor

- Tel : 13910707690

More > Other products from this company