Liaoyang Hongji Machinery Co., Ltd.

Basic Information

- Model No.: LW 250

- Packaging: standard exported wooden case for jucice clarified decanter centrifuge

- Delivery Time: 40 Days

- Place of Origin: Liaoning, China (Mainland)

- Brand: HJ dewatering decanter centrifuge

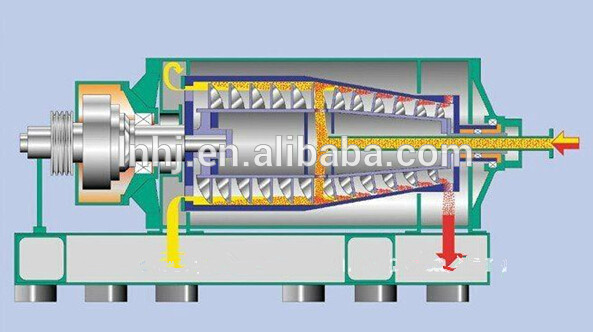

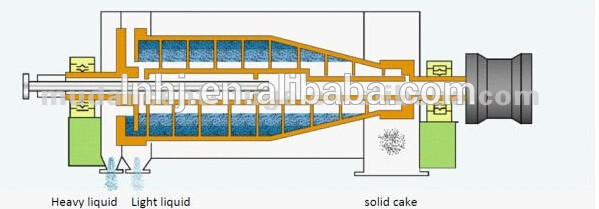

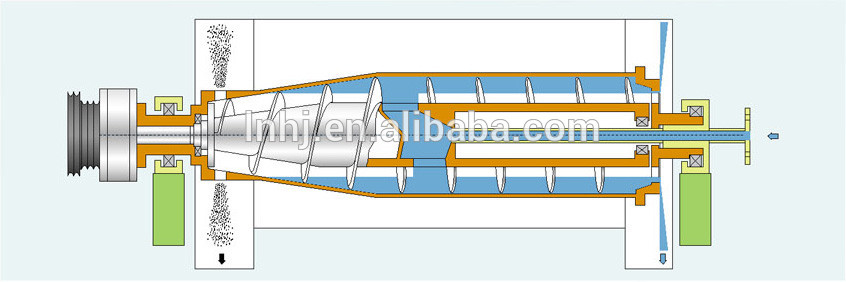

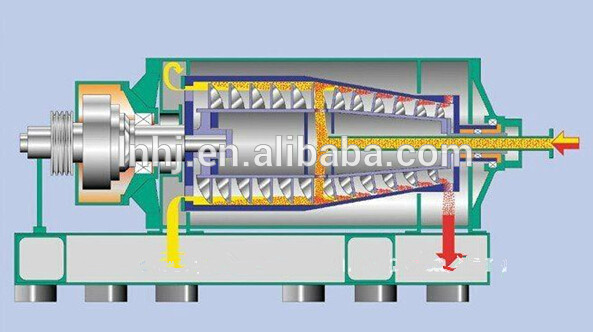

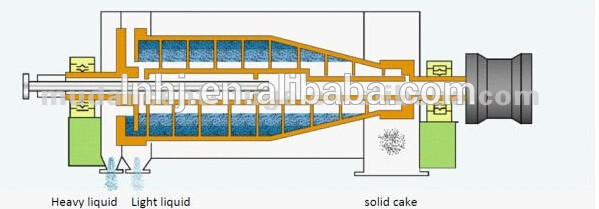

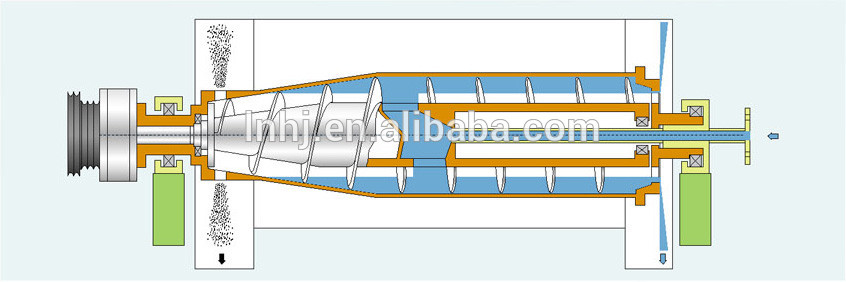

Horizontal fruit juice centrifuge separator Product Description Working Principle : horizontal fruit juice centrifuge separator separates solids from one or two liquid phases in one single continuous process. This is done using centrifugal forces that can be well beyond 3000 times greater than gravity. It consists of a solid cylindirical bowl rotating at high speed, a scroll rotating at the same axis with a slightly different speed, a drive group adjusting the speed difference and the body which carries all the rotating elements. Liquid and suspended solids are fed along the centre line to a distribution room within the bowl and then accelerated into the bowl by centrifugal force through the feeding point. This centrifugal force then causes the suspended solids to settle and accumulate at the bowl wall. Sludge cake is discharged by scroll from the conical part meanwhile clarified liquid flows back along the bowl and is discharged through the cylindirical end of the bowl by plates which can adjust the level of clarified liquid. A decanter centrifuge is a device, which employs a high rotational speed to separate components of different densities. This becomes relevant in the majority of industrial jobs where solids, liquids and gases are merged into a single mixture and the separation of these different phases is necessary. A decanter centrifuge separates solid materials from liquids in slurry and therefore plays an important role in wastewater treatment, chemical, oil and food processing industries. There are several factors that affect the performance of a decanter centrifuge and some design heuristics to be followed which are dependent upon given applications. The operating principle of a decanter centrifuge is based on gravitational separation. Naturally, a component with a higher density would fall to the bottom of a mixture, while the less dense component would be suspended above it. A decanter centrifuge increases the rate of settling through the use of continuous rotation, producing a gravitational force between 1000 to 4000 times that of normal gravitational force. This reduces the settling time of the components by a large magnitude, whereby mixtures previously having to take hours to settle can be settled in a matter of seconds using a decanter centrifuge. This form of separation enables more rapid and controllable results The main application of .vinasse dewatering decanter centrifuge is to separate large amounts of solids from liquids on a continuous basis. They are also used to wash and dry various solids in industry, such as polystyrene beads, clarify liquids and concentrate solids. Table 1.0 displays various examples of the utilisation of decanter centrifuges in various industries. Generally the decanter centrifuge has more advantages than disadvantages; however there are some limitations when compared to other processes. Advantages: 1 leather sludge Decanter Centrifugeave a clean appearance and have little to no odour problems. 2.Not only is the device easy to install and fast at starting up and shutting down, but also only requires a small area for operation compared to other competitive processes. 3.The decanter centrifuge is versatile as different lengths of the cylindrical bowl section and the cone angle can be selected for different applications. Also the system can be pre-programmed with various design curves to predict the sludge type, while some competitive processes, such as a belt filter press, cannot change the belt type to operate for different sludge types.Its versatility allows the machine to have various functions such as operating for thickening or dewatering. The machine can operate with a higher throughput capacity than smaller machines.This also reduces the number of units required. 4.The device is simple to optimise and operate as it has few major variables and reliable feedback information. 5.The decanter centrifuge has reduced labour costs compared to other processes, as it requires low continuous maintenance and operator attention. 6.Compared to some competitive process such as the belt filter process, the decanter centrifuge has more process flexibility and higher levels of performance. Limitation for horizontal fruit juice centrifuge separator : 1.The decanter centrifuge cannot separate biological solids with very small density differences, such as cells and viruses.A competitive process that is capable of separating these difficult-to-separate solids is the tubular-bowl centrifuge. 2.The machine can be very noisy and can cause vibration. 3.The device has a high-energy consumption due to high G-forces. 4.The decanter centrifuge has high equipment capital costs. Hard surfacing and abrasion protection materials are required for the scroll to reduce wear and therefore reduce the maintenance of the scroll wear. The main types of .vinasse dewatering decanter centrifuges are the vertical orientation, horizontal orientation and Conveyor or Scroll. In leather sludge Decanter Centrifuge the rotating assembly is mounted vertically with its weight supported by a single bearing at the bottom or suspended from the top.The gearbox and bowl are suspended from the drive head, which is connected to the frame.The vertical decanter allows for high temperature or high-pressure operation due to the orientation and the rotational seals provided at one end. However, this makes the device more expensive than the horizontal decanter centrifuge, which is non-pressurised and open. The advantage of the vertical machine over the horizontal machine is that the noise emitted during production is much lower due to less vibration. In horizontal decanter centrifuges, as shown in figure 1, the rotating assembly is mounted horizontally with bearings on each end to a rigid frame, which provides a good sealing surface for high-pressure applications.The feed enters through one end of the bearings, while the gearbox is attached to the other end and is operated below critical speed.Capacities range up to 40,000 pounds (18,000 kg) of solids per hour with liquid feed rates of up to 300 US gallons (1.1 m3) per minute. The horizontal machine is arranged in a way that slurry can be introduced at the centre of a rotating horizontal cylindrical bowl. The scroll discharge screw forces the solids to one end of the bowl as it is collected on the walls. This orientation is the most common design implemented in industry. Working principle drawing for horizontal fruit juice centrifuge separator:  LW series decanter centrifuge is a horizontal centrifuge with continuous feeding and continuous discharging. The settling speed is determined by particle size, particle shape, difference in density between solids and liquids as well as their viscosity.

LW series decanter centrifuge is a horizontal centrifuge with continuous feeding and continuous discharging. The settling speed is determined by particle size, particle shape, difference in density between solids and liquids as well as their viscosity.

Screw Conveyor Drum Feature ♦ Main parts such as the bowl and conveyor are made of corrosion-resistant stainless steel or duplex steel, offering high maximum bowl speed and high centrifugal force. Tungsten Carbide Tiles ♦ Optional planetary gearbox and hydraulic gearbox, offering wide range of differential speed adjustment

Screw Conveyor Drum Feature ♦ Main parts such as the bowl and conveyor are made of corrosion-resistant stainless steel or duplex steel, offering high maximum bowl speed and high centrifugal force. Tungsten Carbide Tiles ♦ Optional planetary gearbox and hydraulic gearbox, offering wide range of differential speed adjustment  Multiple safety protection: bowl speed and differential speed detection, over-vibration protection, motor overload and overheat protection, bearing temperature monitoring, conveyor torque protection and gas-tight explosion-proof protection. Technical Parameters

Multiple safety protection: bowl speed and differential speed detection, over-vibration protection, motor overload and overheat protection, bearing temperature monitoring, conveyor torque protection and gas-tight explosion-proof protection. Technical Parameters  Structure drawing:

Structure drawing:

Packaging & Shipping Packaging: Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion. Fumigation-free package helps the smooth customs clearance. The big size machine will be fixed in container without package. Shipping: For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely. For FCL, we get the container and do container loading by our skillful workers carefully. For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

Packaging & Shipping Packaging: Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion. Fumigation-free package helps the smooth customs clearance. The big size machine will be fixed in container without package. Shipping: For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely. For FCL, we get the container and do container loading by our skillful workers carefully. For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

LW series decanter centrifuge is a horizontal centrifuge with continuous feeding and continuous discharging. The settling speed is determined by particle size, particle shape, difference in density between solids and liquids as well as their viscosity.

LW series decanter centrifuge is a horizontal centrifuge with continuous feeding and continuous discharging. The settling speed is determined by particle size, particle shape, difference in density between solids and liquids as well as their viscosity.

Screw Conveyor Drum Feature ♦ Main parts such as the bowl and conveyor are made of corrosion-resistant stainless steel or duplex steel, offering high maximum bowl speed and high centrifugal force. Tungsten Carbide Tiles ♦ Optional planetary gearbox and hydraulic gearbox, offering wide range of differential speed adjustment

Screw Conveyor Drum Feature ♦ Main parts such as the bowl and conveyor are made of corrosion-resistant stainless steel or duplex steel, offering high maximum bowl speed and high centrifugal force. Tungsten Carbide Tiles ♦ Optional planetary gearbox and hydraulic gearbox, offering wide range of differential speed adjustment  Multiple safety protection: bowl speed and differential speed detection, over-vibration protection, motor overload and overheat protection, bearing temperature monitoring, conveyor torque protection and gas-tight explosion-proof protection. Technical Parameters

Multiple safety protection: bowl speed and differential speed detection, over-vibration protection, motor overload and overheat protection, bearing temperature monitoring, conveyor torque protection and gas-tight explosion-proof protection. Technical Parameters  Structure drawing:

Structure drawing:

Packaging & Shipping Packaging: Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion. Fumigation-free package helps the smooth customs clearance. The big size machine will be fixed in container without package. Shipping: For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely. For FCL, we get the container and do container loading by our skillful workers carefully. For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

Packaging & Shipping Packaging: Stable wooden package protects machine from strike and damage. Wound plastic film keeps machine out of damp and corrosion. Fumigation-free package helps the smooth customs clearance. The big size machine will be fixed in container without package. Shipping: For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely. For FCL, we get the container and do container loading by our skillful workers carefully. For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

Supplier Information

Liaoyang Hongji Machinery Co., Ltd.

[ Liaoning China ]

- Business Type : Manufacturer , Trade Company

- Product/Service : Centrifuge , Separator , Disk Centrifuge

- Tel : 13841990225

More > Other products from this company