Shijiazhuang Nainate Screens Pump Co., Ltd.

Basic Information

- Model No.: NH

- Packaging: Plywood box or according to customers\' request for slurry pump

- Delivery Time: 20 Days

- Place of Origin: Hebei, China (Mainland)

- Brand: NNT

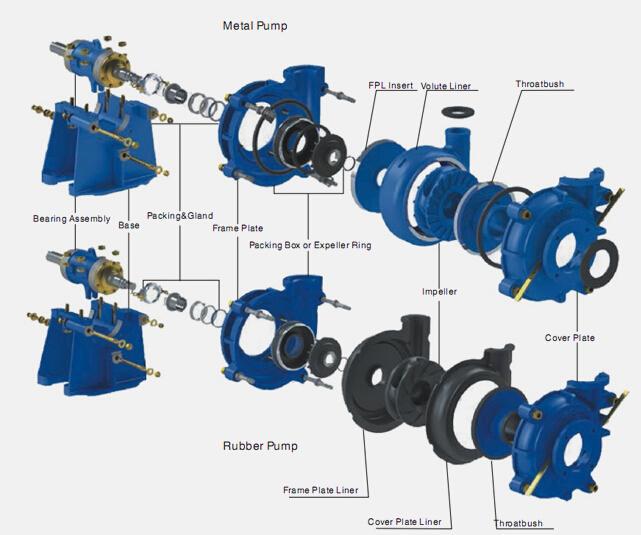

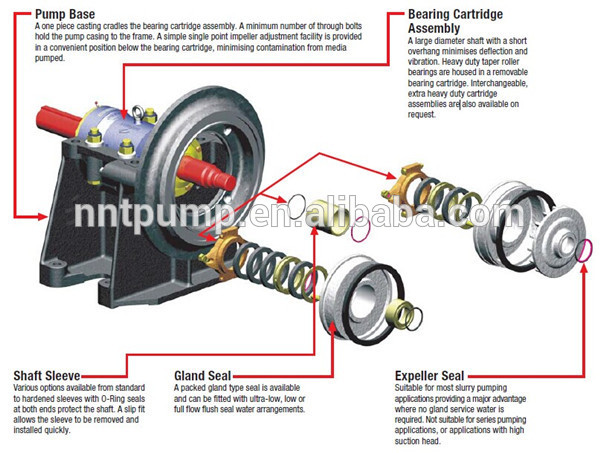

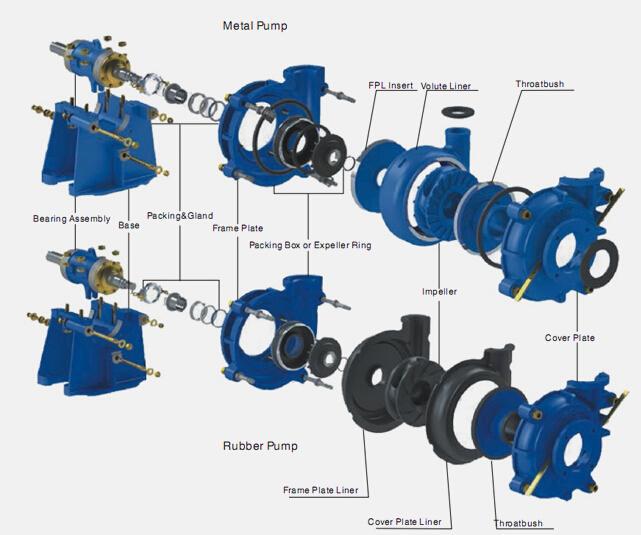

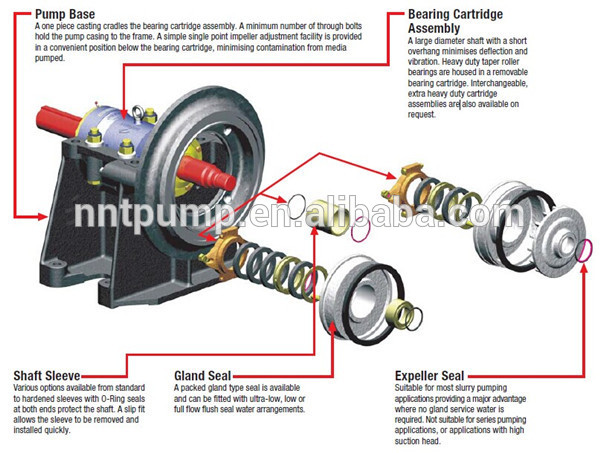

ISO standard horizontal slurry pump, solid slurry pump, ash slurry pump Design and Products Be adapt to covey heavy abrasion,high concentration dreg, NH slurry pump's body is used double-deck structure,in other words, being made of inside lining and outside shell.  1, Bearing assembly – a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. 2, Liners – easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal rings back all liner joints. 3, Casing – Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety. 4, Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. 5, Throatbush – wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. 6, One-piece frame – a very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance. There are three types of shaft seal for choose, expeller seal, packing seal and mechanical seal.

1, Bearing assembly – a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. 2, Liners – easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal rings back all liner joints. 3, Casing – Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety. 4, Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. 5, Throatbush – wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. 6, One-piece frame – a very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance. There are three types of shaft seal for choose, expeller seal, packing seal and mechanical seal.  A wide variety of impellers and shaft seals provide a perfect fit for a wide range of applications. The NH slurry pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost. The NH slurry pump provides a complete selection for most all duties in the mill. From cyclone feed to regrind, flotation and tailings, the NH slurry pump is the best choice.

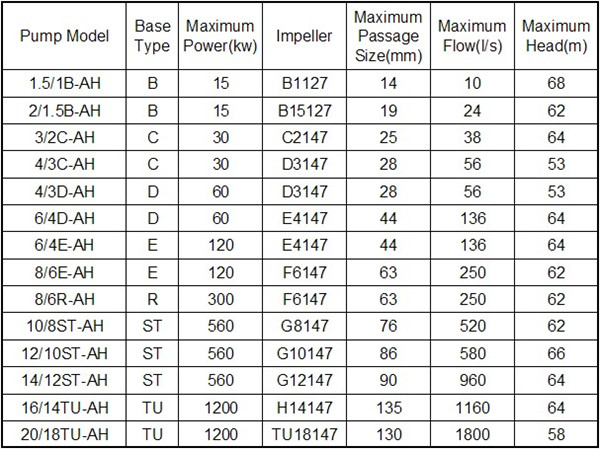

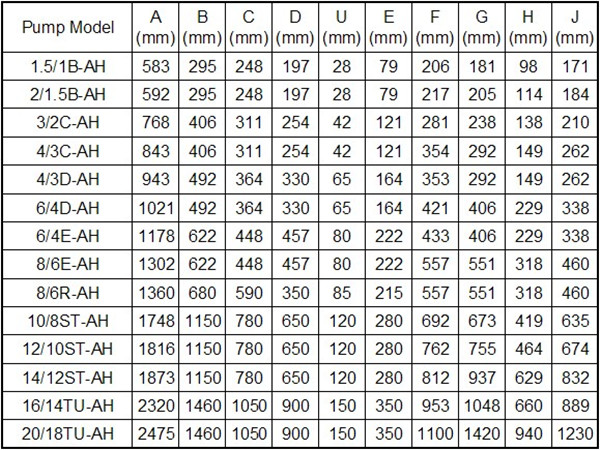

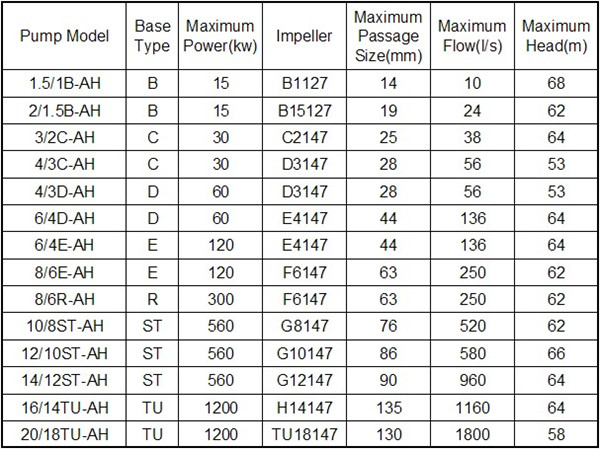

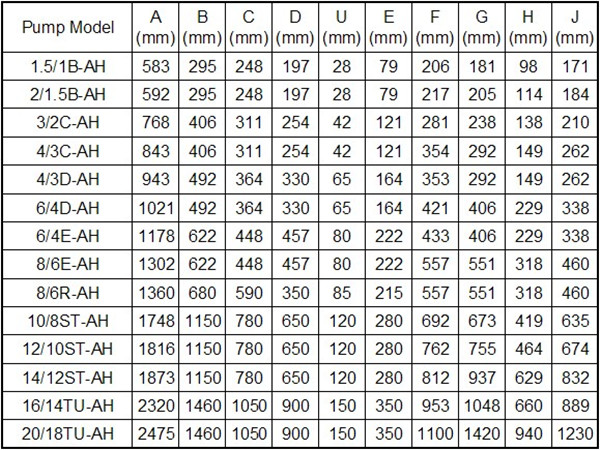

A wide variety of impellers and shaft seals provide a perfect fit for a wide range of applications. The NH slurry pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost. The NH slurry pump provides a complete selection for most all duties in the mill. From cyclone feed to regrind, flotation and tailings, the NH slurry pump is the best choice.  Notation & Explanation For example:6/4E-NH 6: Suction diameter (inch) 4: Discharge diameter (inch) E: Base type NH: Heavy abrasive slurry pump Performance & Dimensions

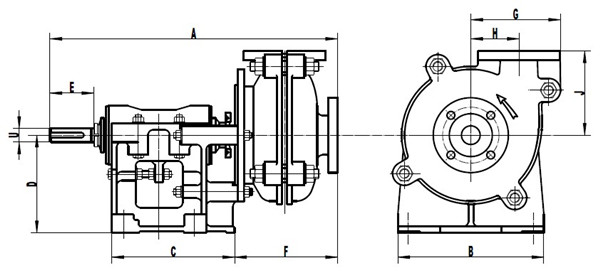

Notation & Explanation For example:6/4E-NH 6: Suction diameter (inch) 4: Discharge diameter (inch) E: Base type NH: Heavy abrasive slurry pump Performance & Dimensions

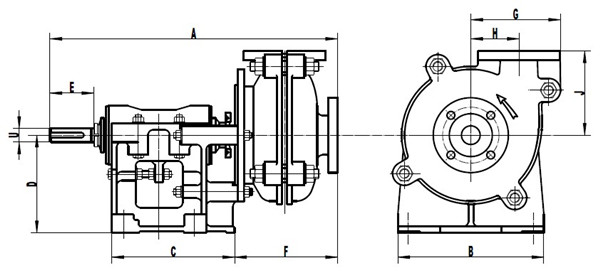

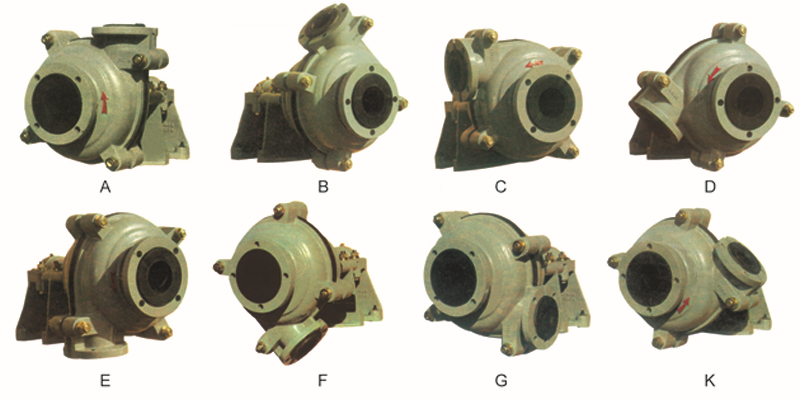

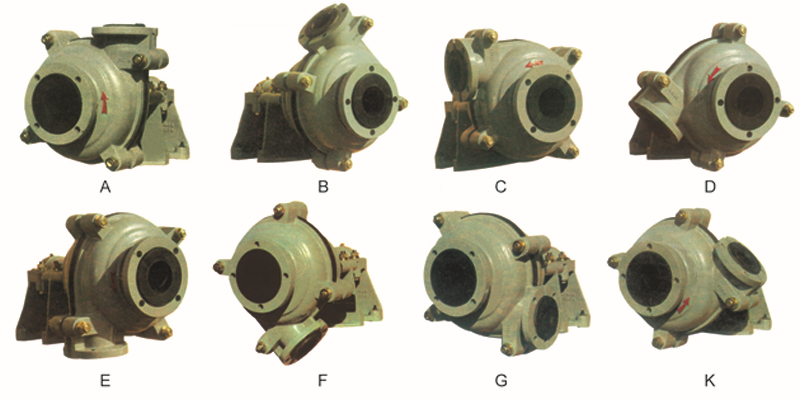

The discharge can be oriented to any eight positions by 45 degrees to suit installations and applications.

The discharge can be oriented to any eight positions by 45 degrees to suit installations and applications.  There are the drive types, including but not limited to the follows.

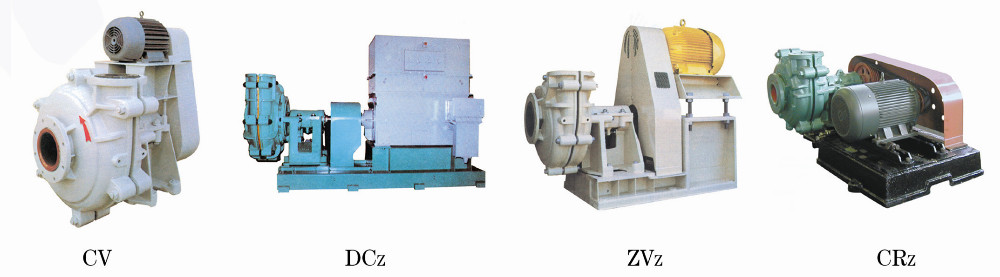

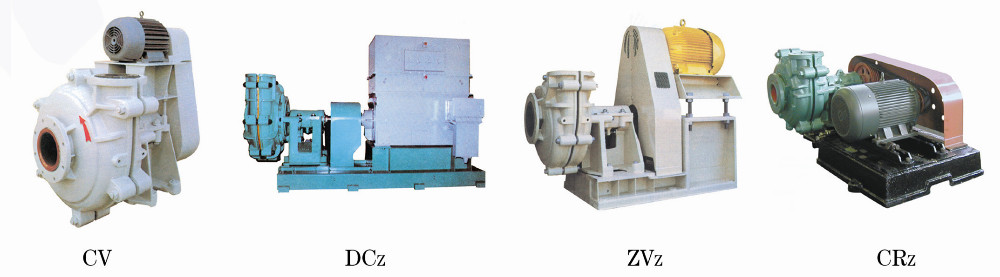

There are the drive types, including but not limited to the follows.  Manufacturing Process Because we are a slurry pump Original Equipment Manufacturer (OEM) with performance curves and original drawings, we know the exacting tolerances and engineering standards required to build and maintain these slurry pumps. We have advanced and complete production line, respectively the casting, heat treatment, machining, product assembly workshops.

Manufacturing Process Because we are a slurry pump Original Equipment Manufacturer (OEM) with performance curves and original drawings, we know the exacting tolerances and engineering standards required to build and maintain these slurry pumps. We have advanced and complete production line, respectively the casting, heat treatment, machining, product assembly workshops.  Quality Management The quality management systems of Nainater slurry pump are accredited to ISO 9001:2000 and our environmental management systems are accredited to ISO 14001:2004.

Quality Management The quality management systems of Nainater slurry pump are accredited to ISO 9001:2000 and our environmental management systems are accredited to ISO 14001:2004.  Related Products

Related Products

Contact

Contact

1, Bearing assembly – a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. 2, Liners – easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal rings back all liner joints. 3, Casing – Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety. 4, Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. 5, Throatbush – wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. 6, One-piece frame – a very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance. There are three types of shaft seal for choose, expeller seal, packing seal and mechanical seal.

1, Bearing assembly – a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. 2, Liners – easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal rings back all liner joints. 3, Casing – Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety. 4, Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. 5, Throatbush – wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. 6, One-piece frame – a very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance. There are three types of shaft seal for choose, expeller seal, packing seal and mechanical seal.  A wide variety of impellers and shaft seals provide a perfect fit for a wide range of applications. The NH slurry pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost. The NH slurry pump provides a complete selection for most all duties in the mill. From cyclone feed to regrind, flotation and tailings, the NH slurry pump is the best choice.

A wide variety of impellers and shaft seals provide a perfect fit for a wide range of applications. The NH slurry pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost. The NH slurry pump provides a complete selection for most all duties in the mill. From cyclone feed to regrind, flotation and tailings, the NH slurry pump is the best choice.  Notation & Explanation For example:6/4E-NH 6: Suction diameter (inch) 4: Discharge diameter (inch) E: Base type NH: Heavy abrasive slurry pump Performance & Dimensions

Notation & Explanation For example:6/4E-NH 6: Suction diameter (inch) 4: Discharge diameter (inch) E: Base type NH: Heavy abrasive slurry pump Performance & Dimensions

The discharge can be oriented to any eight positions by 45 degrees to suit installations and applications.

The discharge can be oriented to any eight positions by 45 degrees to suit installations and applications.  There are the drive types, including but not limited to the follows.

There are the drive types, including but not limited to the follows.  Manufacturing Process Because we are a slurry pump Original Equipment Manufacturer (OEM) with performance curves and original drawings, we know the exacting tolerances and engineering standards required to build and maintain these slurry pumps. We have advanced and complete production line, respectively the casting, heat treatment, machining, product assembly workshops.

Manufacturing Process Because we are a slurry pump Original Equipment Manufacturer (OEM) with performance curves and original drawings, we know the exacting tolerances and engineering standards required to build and maintain these slurry pumps. We have advanced and complete production line, respectively the casting, heat treatment, machining, product assembly workshops.  Quality Management The quality management systems of Nainater slurry pump are accredited to ISO 9001:2000 and our environmental management systems are accredited to ISO 14001:2004.

Quality Management The quality management systems of Nainater slurry pump are accredited to ISO 9001:2000 and our environmental management systems are accredited to ISO 14001:2004.  Related Products

Related Products

Contact

Contact

Supplier Information

Shijiazhuang Nainate Screens Pump Co., Ltd.

[ Hebei China ]

- Business Type : Manufacturer

- Product/Service : Slurry pump , Dredging pump , Desulfurization pump

- Tel : 13739734494

More > Other products from this company