Jiangsu TX Plastic Optical Fibers Co., Ltd.

Basic Information

- Model No.: TX-1-001

- Packaging: Standard packing and customer \'s demand can be satisfied.

- Delivery Time: 3 Days

- Place of Origin: Jiangsu, China (Mainland)

- Brand: TXPOF

Specifications 1.Dream-like effect

2.ISO9001,UL

3.Simple installation, less maintenance

4.High performance, save power

5.Easy to insatll

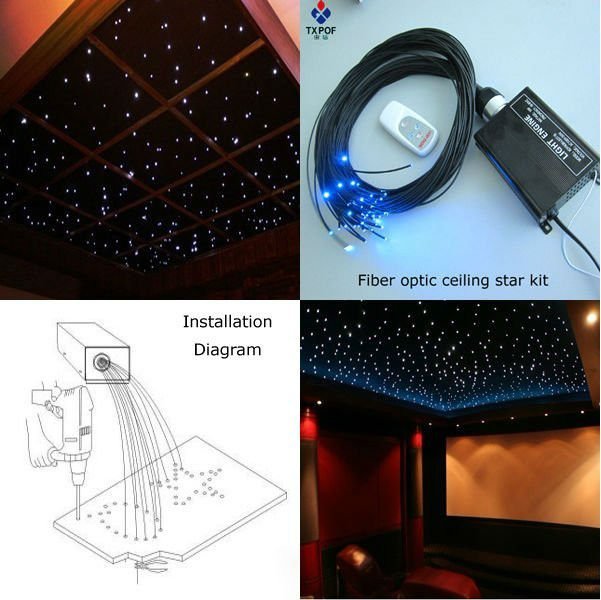

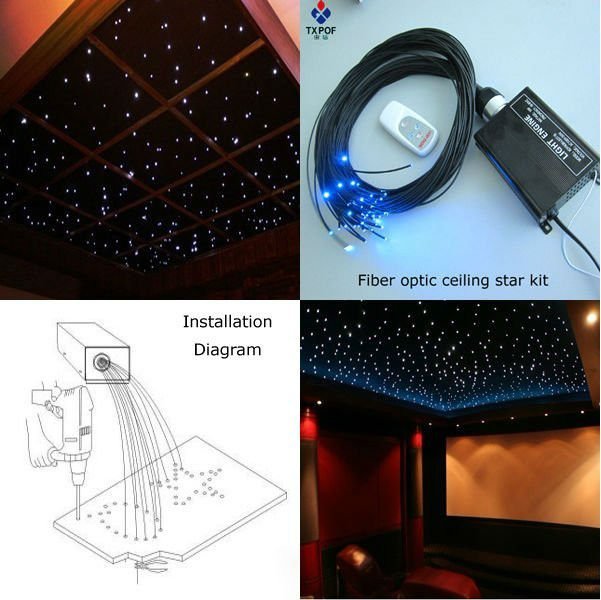

Description: - 1set 16w LED light engine - 150 pcs 0.75mm fiber - decortation area about 4 square meter - 38emitting points per square meter - color change by remote control Features: 1, cold light source, non-ultraviolet, without the acceleration of valuable, 2, separation of light and electricity, safe and reliable application in flammable and explosive occasion, 3, low power, energy saving and environmental friendly, 4, flexible transmission, apply in plastic optical fiber lights and projects of plastic optical fiber decoration, can produce colorful and dream-like effect, 5, cold light source, long life, non-ultraviolet ray, separation of light and electricity, 6, optical fiber display with lower attenuation and high brightness, full color render, clear vision, lower power, easy recycle and long life etc The Advantage & Unique Features of Fiber optic cables 1. Flexibility Fiber optic cable are flexible and can be shaped to conform to almost any curve design. 2. Durability PMMA Optical fibers are strong, durable and impact resistant compared with fragile light bulbs. 3. UV & IR Control Fiber optic cable transmits only cool light filtering out harmful levels of ultra violet ans infra red radiation. This allows safe illumination of perishable items, antiques, fine arts, sensitive textiles and finishes. 4. Color Changing Most power advantage is its color changing ability, creating pleasant ambient depending on individual perference can be preset to gradual changing sequence. 5. Sparking Animation Fiber optic lights can creat a more realistic sparking & twinkling effect, from subtle to animation plus feasibility to creat shooting star pattern. 6. Low Maintenance and energy saver A single light engine can beam up to 250-500 strands of 0.75mm fiber. The light engine can be in an easily accessible location. 7. Weatherproof Outdoor and underwater lighting such swimming pools, fountaions or even illumination in hazardous atmospheres can be done satety with optic lighting, sine the fiber is non-conductive and the power for the light engine can be placed in remote location. The production List of this item

Installation: Note: we do not suggest the use of the superglue as it can cause the fiber tails become brittle and prior to breakage, resulting in a loss of light. Please install each illuminator in an accessible location that allows each cable to reach the ceiling with 60cm of slack. Step1: Drill a small holes’ size same as the diameter of end fitting on the ceiling. Step 2: Insert the end piece through the hole from the below ceilling and screw it. Step 3: Insert the fiber cable into the end fitting and secure the fiber cable in place with silicone sealant. Allow the sealant to dry. Step 4: Insert the plug into the power socket. It is all completed. Application pictures of the product :

2.ISO9001,UL

3.Simple installation, less maintenance

4.High performance, save power

5.Easy to insatll

Description: - 1set 16w LED light engine - 150 pcs 0.75mm fiber - decortation area about 4 square meter - 38emitting points per square meter - color change by remote control Features: 1, cold light source, non-ultraviolet, without the acceleration of valuable, 2, separation of light and electricity, safe and reliable application in flammable and explosive occasion, 3, low power, energy saving and environmental friendly, 4, flexible transmission, apply in plastic optical fiber lights and projects of plastic optical fiber decoration, can produce colorful and dream-like effect, 5, cold light source, long life, non-ultraviolet ray, separation of light and electricity, 6, optical fiber display with lower attenuation and high brightness, full color render, clear vision, lower power, easy recycle and long life etc The Advantage & Unique Features of Fiber optic cables 1. Flexibility Fiber optic cable are flexible and can be shaped to conform to almost any curve design. 2. Durability PMMA Optical fibers are strong, durable and impact resistant compared with fragile light bulbs. 3. UV & IR Control Fiber optic cable transmits only cool light filtering out harmful levels of ultra violet ans infra red radiation. This allows safe illumination of perishable items, antiques, fine arts, sensitive textiles and finishes. 4. Color Changing Most power advantage is its color changing ability, creating pleasant ambient depending on individual perference can be preset to gradual changing sequence. 5. Sparking Animation Fiber optic lights can creat a more realistic sparking & twinkling effect, from subtle to animation plus feasibility to creat shooting star pattern. 6. Low Maintenance and energy saver A single light engine can beam up to 250-500 strands of 0.75mm fiber. The light engine can be in an easily accessible location. 7. Weatherproof Outdoor and underwater lighting such swimming pools, fountaions or even illumination in hazardous atmospheres can be done satety with optic lighting, sine the fiber is non-conductive and the power for the light engine can be placed in remote location. The production List of this item

| Model | Light Engine | Mixed fiber optic QTY and Dia | Fiber length | Cover square | Average star(points/M*M) | Color |

| TX-1-001 | 16W LED light engine | 150pcs:0.75mm | 2m | 2*2m | 38 | RGB(Seven color) or single color |

| TX-1-002 | 16W LED light engine | 200pcs:0.75mm | 2m | 2*2m | 50 | RGB(Seven color) or single color |

| TX-1-003 | 16W LED light engine | 150pcs:1.0mm | 2m | 2*2m | 38 | RGB(Seven color) or single color |

| TX-1-004 | 16W LED light engine | 200pcs:1.0mm | 2m | 2*2m | 50 | RGB(Seven color) or single color |

| Model | Light Engine | Mixed fiber optic QTY and Dia | Fiber length | Cover square | Average star(points/M*M) | Color |

| TX-2-001 | 16W LED light engine | 60pcs:0.75mm, 60pcs:1.0mm | 2m | 2*2m | 30 | RGB(Seven color) or single color |

| TX-2-002 | 16W LED light engine | 80pcs:0.75mm, 80pcs:1.0mm | 3m | 2*3m | 26 | RGB(Seven color) or single color |

| TX-2-003 | 16W LED light engine | 110pcs:0.75mm, 110pcs:1.0mm | 3m | 3*3m | 24 | RGB(Seven color) or single color |

| TX-2-004 | 16W LED light engine | 140pcs:0.75mm, 140pcs:1.0mm | 4m | 4*4m | 17 | RGB(Seven color) or single color |

| Model | Light Engine | Mixed fiber optic QTY and Dia | Fiber length | Cover square | Average star(points/M*M) | Color |

| TX-3-001 | 16W LED light engine | 100pcs:0.75mm, 80pcs:1.0mm, 8pcs:1.5mm | 2m | 2*2m | 47 | RGB(Seven color) or single color |

| TX-3-002 | 16W LED light engine | 150pcs:0.75mm, 80pcs:1.0mm, 8pcs:1.5mm | 3m | 2*3m | 40 | RGB(Seven color) or single color |

| TX-3-003 | 16W LED light engine | 200pcs:0.75mm, 100pcs:1.0mm, 8pcs:1.5mm | 3m | 3*3m | 34 | RGB(Seven color) or single color |

| TX-3-004 | 16W LED light engine | 240pcs:0.75mm, 100pcs:1.0mm, 8pcs:1.5mm | 4m | 3*4m | 28 | RGB(Seven color) or single color |

Supplier Information

Jiangsu TX Plastic Optical Fibers Co., Ltd.

[ Jiangsu China ]

- Business Type : Manufacturer , Trade Company

- Product/Service : Toslink Cable , Plastic Optical Fiber & Patch Cord , Sensing Fiber

- Tel : 18652599863,18652599881

More > Other products from this company