Ma'anshan Longxin Industry Co.,Ltd.

Basic Information

- Model No.: 2.5 layer forming fabric

- Packaging: 1.standard export packing with plastic bag in plywood case.2.As your requirement.

- Delivery Time: 25 Days

- Place of Origin: Anhui, China (Mainland)

- Brand: Sinostar

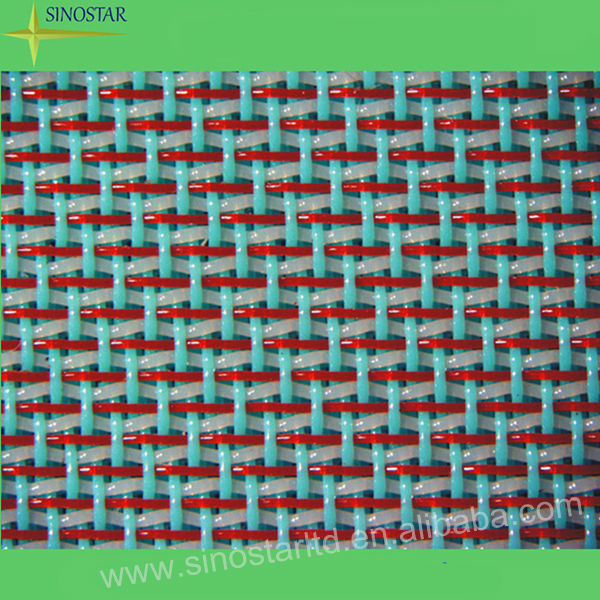

Specifications 2.5 layer forming fabric

1.100% PET material.

2.Smooth surface.

3.Good Air permeation.

4.Durable.

16 shed 2.5 layer forming fabric for paper machine

Product Description A sheet of paper begins in the forming section, where a mixture of 99% water and 1% cellulose fiber is introduced evenly across a forming screen/fabric, which acts as both a sheet conveyor and a dewatering device. It is here that the paper sheet is formed and the initial water removal occurs. As the fabric moves, water drains through it, while the fibers and fillers that form the sheet remain on top. Today, forming fabrics have an average operating life of 45 to 60 days. Multilayer technology offered by Maanshan Sinostar is the standard today on world-class high-speed machines. Paper machine forming screens/fabrics are designed to retain as much fiber and other furnish components as possible while allowing water to drain through them as quickly as possible. These fabrics are typically produced from monofilament strands or yarns that are woven together in a pattern that can be classified by their fabric style (or weave);mesh, count, and diameter; surface topography; and air permeability. This module discusses how each of these characteristics affect final sheet quality. Polyester Forming Screen Categories According to the weaving, paper making fabrics can be divided into 4-shed single layer fabrics, 5-shed single layer fabrics, 8-shed single layer fabrics, 7-shed double layer fabrics, 8-shed double layer fabrics, 8-shed double and a half layer fabrics, 16-shed double and a half layer fabrics. 4-shed single layer fabrics is used in making culture paper, printing paper and packing paper. 5-shed single layer fabrics is used in making printed toilet paper, culture paper and packing paper. 8-shed single layer fabrics is mainly used to making bag paper,kraft paper,sheet lined board , corrugated paper and cardboard paper etc.

7-shed double layer fabrics is suitable for making quality printing paper and tissue paper etc. 8-shed double layer fabrics is suitable for making quality printing paper, offset paper, tissue paper and the surface pulp and inner pulp of the board paper etc.

8-shed,16-shed double and a half layer fabrics is suitable for various papers of the high speed paper machine. Company introduction Maanshan Sinostar Industry Co.,Ltd is a supplier of polyester forming fabrics and dryer fabrics used in the paper industry. They are produced in factories in China, which has more than 10 years worth of experience with the production of paper machine clothing.We use only the best plastic yarns from reliable suppliers and guarantee the highest quality of our products. We aim at supply in our customers with a suitable fabric and achieving the best possible results according to their demands. In order to do that, we want to learn about their goals and to understand the technological processes for which our fabrics will be used. We also provide continuous technical support and service. We offer polyester forming fabrics dryer fabrics for all paper grades including special fabrics, which are resistant to hydrolysis and stickies for the range of air permeability from 80 to 1,000 CFM. Our products can be used in a wide variety of applications for the solid liquid separation, e.g. dewatering of municipal or industrial sludge in belt filter presses or gravity thickeners, filtration in horizontal vacuum filters, thickening in drum filters, conveyor belts, process belts in various industries,etc.We can also produce fabrics according to customers’ specifications. Product show

Packaging & Shipping

Packaging & Shipping  Our Services Highly inspecting equipments in every working procedure, quality comes first; Assisting our customers for foundation construction of equipments; Dispatching engineers to install and debug equipments; Regularly visit clients to solve production problems; Providing life-long maintenance service; Fast & Safe Delivery; Buying Guides How to choice the best-suitable and reliable Forming fabrics for your paper Machine? 1. PM-speed : 2. CFM : 3. watering drainage ability : 4. Paper grade : 5. Pulp type : We are professional paper machine clothings manufacturer, We sell products in good service and high quality with reasonable prices. Please feel free to contact with us if any trouble happened durning your PMC running. Any question,please feel free to contact us.

Our Services Highly inspecting equipments in every working procedure, quality comes first; Assisting our customers for foundation construction of equipments; Dispatching engineers to install and debug equipments; Regularly visit clients to solve production problems; Providing life-long maintenance service; Fast & Safe Delivery; Buying Guides How to choice the best-suitable and reliable Forming fabrics for your paper Machine? 1. PM-speed : 2. CFM : 3. watering drainage ability : 4. Paper grade : 5. Pulp type : We are professional paper machine clothings manufacturer, We sell products in good service and high quality with reasonable prices. Please feel free to contact with us if any trouble happened durning your PMC running. Any question,please feel free to contact us.

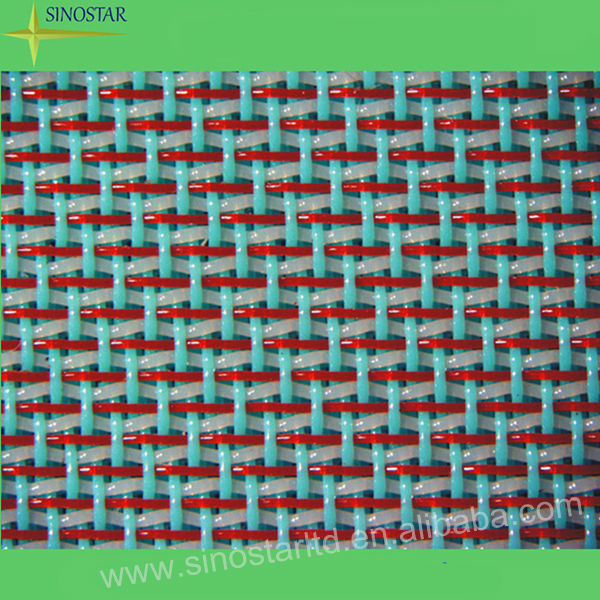

1.100% PET material.

2.Smooth surface.

3.Good Air permeation.

4.Durable.

16 shed 2.5 layer forming fabric for paper machine

| Model of fabric | CXW384516-2 |

| Structure | double and a half layer forming fabric |

| Warp diameter | 0.20mm |

| Weft diameter | 0.2mm, 0.25/0.45mm(PET), 0.45mm(PA66) |

| Warp density (thread/cm) | 49-50 |

| Weft dendity (thread/cm) | 34-35 |

| Air permeability(m3/m2h) | 6200 |

| Surface strength (N/cm) | >1150 |

| Jointing strength (N/cm) | >800 |

| Max elongation at 50N/cm | <0.7% |

| Thickness(mm) | 1.3 |

7-shed double layer fabrics is suitable for making quality printing paper and tissue paper etc. 8-shed double layer fabrics is suitable for making quality printing paper, offset paper, tissue paper and the surface pulp and inner pulp of the board paper etc.

8-shed,16-shed double and a half layer fabrics is suitable for various papers of the high speed paper machine. Company introduction Maanshan Sinostar Industry Co.,Ltd is a supplier of polyester forming fabrics and dryer fabrics used in the paper industry. They are produced in factories in China, which has more than 10 years worth of experience with the production of paper machine clothing.We use only the best plastic yarns from reliable suppliers and guarantee the highest quality of our products. We aim at supply in our customers with a suitable fabric and achieving the best possible results according to their demands. In order to do that, we want to learn about their goals and to understand the technological processes for which our fabrics will be used. We also provide continuous technical support and service. We offer polyester forming fabrics dryer fabrics for all paper grades including special fabrics, which are resistant to hydrolysis and stickies for the range of air permeability from 80 to 1,000 CFM. Our products can be used in a wide variety of applications for the solid liquid separation, e.g. dewatering of municipal or industrial sludge in belt filter presses or gravity thickeners, filtration in horizontal vacuum filters, thickening in drum filters, conveyor belts, process belts in various industries,etc.We can also produce fabrics according to customers’ specifications. Product show

Packaging & Shipping

Packaging & Shipping  Our Services Highly inspecting equipments in every working procedure, quality comes first; Assisting our customers for foundation construction of equipments; Dispatching engineers to install and debug equipments; Regularly visit clients to solve production problems; Providing life-long maintenance service; Fast & Safe Delivery; Buying Guides How to choice the best-suitable and reliable Forming fabrics for your paper Machine? 1. PM-speed : 2. CFM : 3. watering drainage ability : 4. Paper grade : 5. Pulp type : We are professional paper machine clothings manufacturer, We sell products in good service and high quality with reasonable prices. Please feel free to contact with us if any trouble happened durning your PMC running. Any question,please feel free to contact us.

Our Services Highly inspecting equipments in every working procedure, quality comes first; Assisting our customers for foundation construction of equipments; Dispatching engineers to install and debug equipments; Regularly visit clients to solve production problems; Providing life-long maintenance service; Fast & Safe Delivery; Buying Guides How to choice the best-suitable and reliable Forming fabrics for your paper Machine? 1. PM-speed : 2. CFM : 3. watering drainage ability : 4. Paper grade : 5. Pulp type : We are professional paper machine clothings manufacturer, We sell products in good service and high quality with reasonable prices. Please feel free to contact with us if any trouble happened durning your PMC running. Any question,please feel free to contact us.

Supplier Information

Ma'anshan Longxin Industry Co.,Ltd.

[ Anhui China ]

- Business Type : Trade Company

- Product/Service : paper machine clothing , refiner plate , screen basket

- Tel : 13965600752

More > Other products from this company