Ningbo Rilson Sealing Material Co., Ltd.

- Model No.: RS1

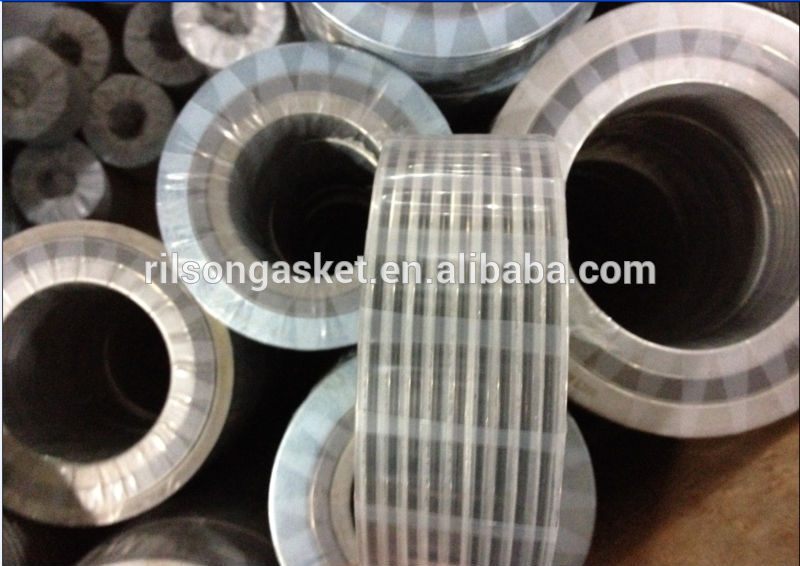

- Packaging: SWG with outer ringpackage plastic clips to keep the space every gaskets packaged by plastic outside

- Delivery Time: 15 Days

- Place of Origin: Zhejiang, China (Mainland)

- Brand: Rilson

2-Easy to install... Less than half the studs

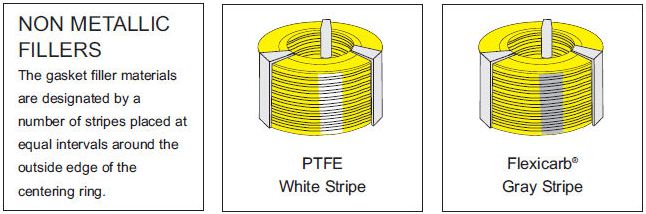

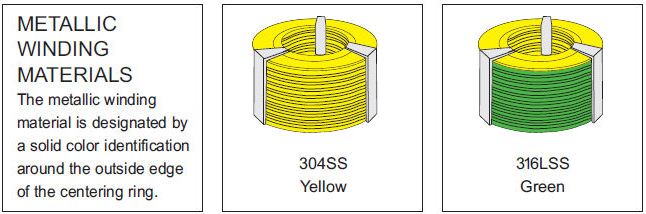

3-Multiple metal windings & fillers available

The concept of spiral wound gasket construction was originated by Flexitallic in 1912, inaugurating the beginning of a new era in safe, effective sealing. And we are the main supplier of spiral wound gasket in China and also the supplier of Flexitallic Group. The primary purpose for this development was the increasingly severe temperatures and pressures used by U.S. refinery operators in the first half of the century. The necessity for a gasket to have the ability to recover cannot be over emphasized. The effects of pressure and temperature fluctuations, the temperature differential across the flange face, together with bolt stress relaxation and creep, demand a gasket with adequate flexibility and recovery to maintain a seal even under these varying service conditions. The Rilson Spiral Wound Gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and pressure in flanged joints and similar assemblies and against virtually every known corrosive and toxic media. Gasket Identification

| Style | Structure | Hoop material | Filler | Inner & outer ring material |

| SWG | With inner & outer rings-RS1-CGI | 304(L),316(L),321,317(L), 31803,Monel,Ti,Ni,INC, Hast. C/B Zr702,Etc. | Graphite,PTFE, Asbestos,Non-asbestos, Mics,Monel,etc. | CS,304(L),316(L),321,317(L), 31803,Monel,Ti,Ni,INC, Hast.C/B Zr702,Etc. |

|  |  |  |

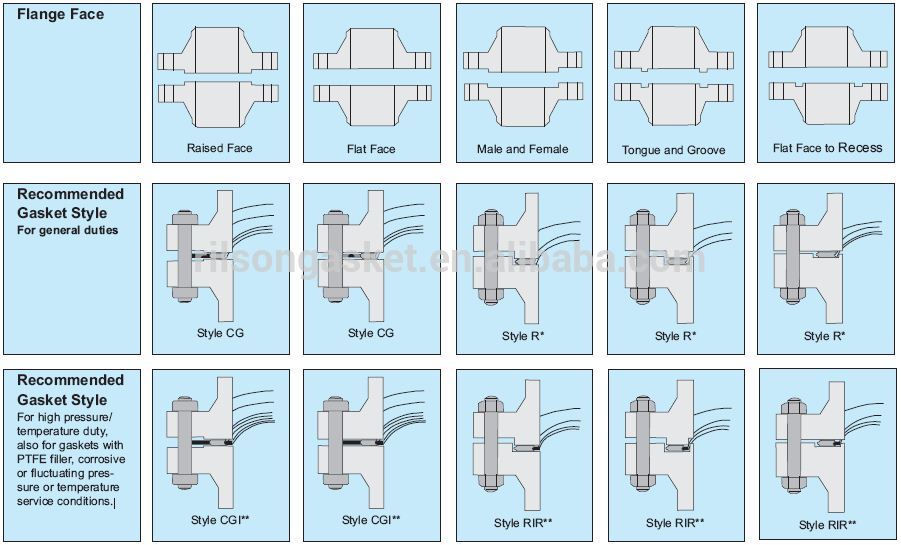

Style CG - Utilizes an external ring which accurately centers gasket on flange face, provides additional radial strength to prevent gasket blow-out and acts as a compression stop. A general purpose gasket suitable for use with flat face and raised face flanges up to and inclusive of class 2500. See note at bottom of page 8 for inner ring requirements. | Style CGI - A Style CG gasket fitted with internal ring which gives an additional compression limiting stop and provides heat and corrosion barrier protecting gasket windings and preventing flange erosion. Suitable for use with flat face and raised face flanges. See note at bottom of page 8 for inner ring requirements. | Style R - Basic construction type. Inner and outer diameters are reinforced with several plies of metal without filler to give greater stability and better compression and sealing characteristics. Suitable for tongue and groove or male and female or grooved to flat face flange assemblies. | Style RIR - Solid inner metal ring acts as a compression stop and fills the annular space between flange bore and the inside diameter of the gasket. Designed to prevent accumulation of solids, reduce turbulent flow of process fluids and minimize erosion at flange faces. Suitable for male and female pipe flanges. |

Working Shop:

Working Shop:  Packing Detail:

Packing Detail:

If you are interested in our products, please contact me in Ali and in Email and I will reply to you as soon as possible. My target of service is to satisfy your requirements. My Email: sales02 at rilson.com.cn

If you are interested in our products, please contact me in Ali and in Email and I will reply to you as soon as possible. My target of service is to satisfy your requirements. My Email: sales02 at rilson.com.cn - Business Type : Manufacturer , Trade Company

- Product/Service : Spiral Wound Gasket , Ring Joint Gasket , Kammprofile Gasket

- Tel : 86-574-63119187