Ningbo Rilson Sealing Material Co., Ltd.

Basic Information

- Model No.: RS1-CG

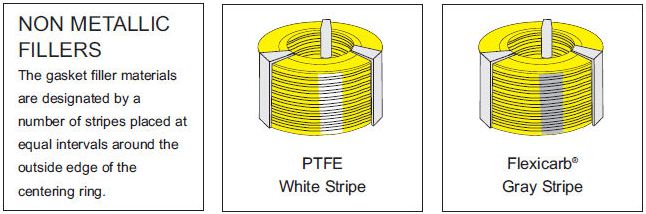

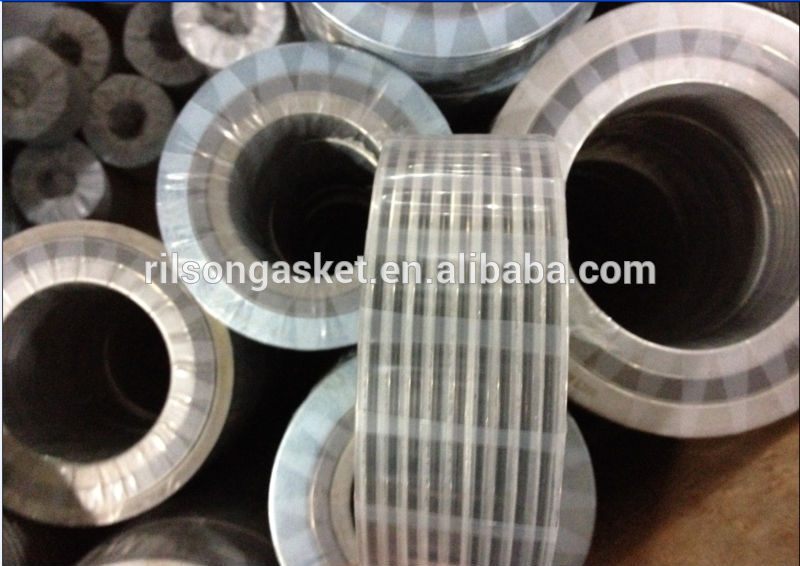

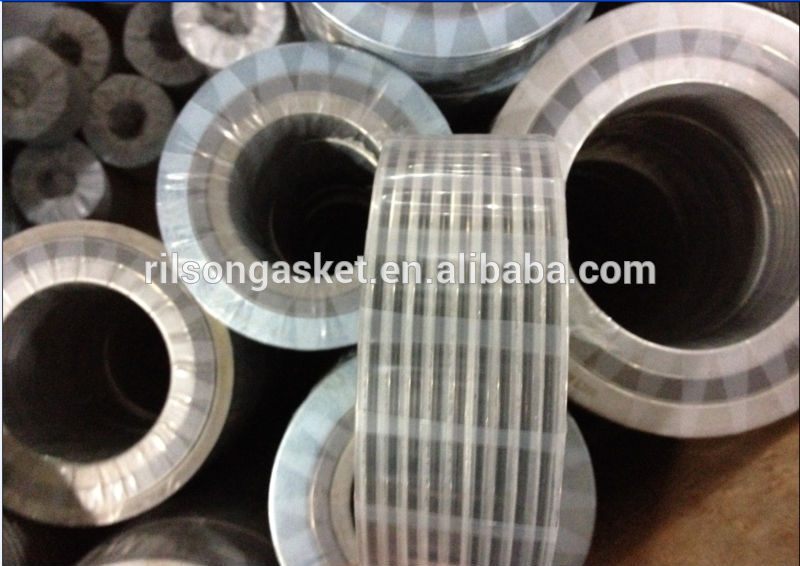

- Packaging: wooden cases, plastic strips as the picture shown

- Delivery Time: 15 Days

- Place of Origin: Zhejiang, China (Mainland)

- Brand: Rilson

Specifications 1-Reduces inventory requirements

2-Easy to installaa Less than half the studs

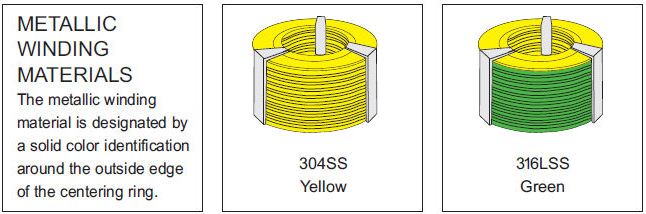

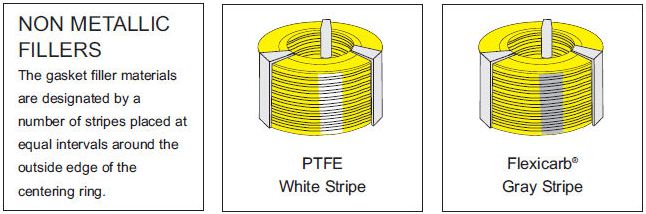

3-Multiple metal windings & fillers available

The spiral wound gasket depends upon the mechanical characteristics of a formed metal spiral strip, rather than the compressive virtues of more traditional gasket materials. This makes it particularly suitable for low or fluctuating bolt loads. The sealing strips, or fillers, are usually graphite, although other materials such as PTFE may be used, the windings are always s/steal. For this type or gasket to work the spiral must not be over compressed, hence one of two types of compression control used. The completed gaskets is fitted into a steel ring of specific thickness. When the gasket is fitted into a flange and the bolt load is applied, flange closure is governed by the outer steel ring of the gasket. To further improve the pressure rating of the spiral wound gasket, s steel ring may be added to the inside. This also protects the windings (particularly the filler), from contamination, or attack by, the product.

Application

Application

Gasket Manufacturer & Material Supplier We are an international manufacturer of gaskets and seals, supplying into many industries and countries all over the world. We have a wide experience of working with many different companies, and of making gaskets and seals for a wide variety of conditions and environments. Why do companies buy from us? Specialist: We have expert knowledge of gaskets and seals. Technology: We use the latest gasket materials and manufacturing technology. Design: We offer part-prototyping and samples. Quality: We hold ISO quality certification (ISO 9001). Accountability: We offer full gasket and material traceability. Strong Customer Relationships: We have a reputation for strong customer relationships. International Strengths Order Quantities: No minimum order quantities. Flexibility: All parts are made to order. We can react to changes in demand. Lead Times: Competitive lead times on international orders. Shipping: International shipping by air or sea. Services We work with our customers to make sure that they design and receive the most economical part, which meets their requirements and specifications. We can manufacture from sample, technical drawing, or straight from electronic drawing file (such as a PDF and DOC files). We also provide our customers with on-going technical advice and support. Company History Rilson has been manufacturing custom gaskets and seals since 2007. Our gaskets have been used in well known buildings, famous works of art, and prototype space vehicles.

Gasket Manufacturer & Material Supplier We are an international manufacturer of gaskets and seals, supplying into many industries and countries all over the world. We have a wide experience of working with many different companies, and of making gaskets and seals for a wide variety of conditions and environments. Why do companies buy from us? Specialist: We have expert knowledge of gaskets and seals. Technology: We use the latest gasket materials and manufacturing technology. Design: We offer part-prototyping and samples. Quality: We hold ISO quality certification (ISO 9001). Accountability: We offer full gasket and material traceability. Strong Customer Relationships: We have a reputation for strong customer relationships. International Strengths Order Quantities: No minimum order quantities. Flexibility: All parts are made to order. We can react to changes in demand. Lead Times: Competitive lead times on international orders. Shipping: International shipping by air or sea. Services We work with our customers to make sure that they design and receive the most economical part, which meets their requirements and specifications. We can manufacture from sample, technical drawing, or straight from electronic drawing file (such as a PDF and DOC files). We also provide our customers with on-going technical advice and support. Company History Rilson has been manufacturing custom gaskets and seals since 2007. Our gaskets have been used in well known buildings, famous works of art, and prototype space vehicles.  Packing Detail

Packing Detail

More interests please kindly send me an email or directly contact my Trademanager and I will reply as soon as possible. My email: sales02 at rilson.com.cn Your success is my business.

More interests please kindly send me an email or directly contact my Trademanager and I will reply as soon as possible. My email: sales02 at rilson.com.cn Your success is my business.

2-Easy to installaa Less than half the studs

3-Multiple metal windings & fillers available

The spiral wound gasket depends upon the mechanical characteristics of a formed metal spiral strip, rather than the compressive virtues of more traditional gasket materials. This makes it particularly suitable for low or fluctuating bolt loads. The sealing strips, or fillers, are usually graphite, although other materials such as PTFE may be used, the windings are always s/steal. For this type or gasket to work the spiral must not be over compressed, hence one of two types of compression control used. The completed gaskets is fitted into a steel ring of specific thickness. When the gasket is fitted into a flange and the bolt load is applied, flange closure is governed by the outer steel ring of the gasket. To further improve the pressure rating of the spiral wound gasket, s steel ring may be added to the inside. This also protects the windings (particularly the filler), from contamination, or attack by, the product.

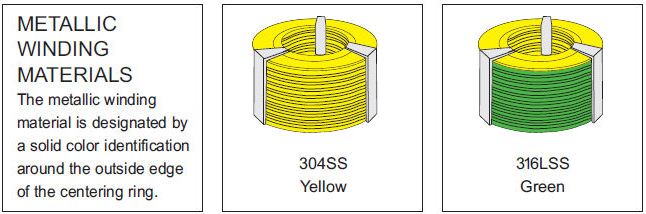

METAL WINDING STRIP | FILLER MATERIALS | CENTRAL RING MATERIALS |

Application

Application

Gasket Manufacturer & Material Supplier We are an international manufacturer of gaskets and seals, supplying into many industries and countries all over the world. We have a wide experience of working with many different companies, and of making gaskets and seals for a wide variety of conditions and environments. Why do companies buy from us? Specialist: We have expert knowledge of gaskets and seals. Technology: We use the latest gasket materials and manufacturing technology. Design: We offer part-prototyping and samples. Quality: We hold ISO quality certification (ISO 9001). Accountability: We offer full gasket and material traceability. Strong Customer Relationships: We have a reputation for strong customer relationships. International Strengths Order Quantities: No minimum order quantities. Flexibility: All parts are made to order. We can react to changes in demand. Lead Times: Competitive lead times on international orders. Shipping: International shipping by air or sea. Services We work with our customers to make sure that they design and receive the most economical part, which meets their requirements and specifications. We can manufacture from sample, technical drawing, or straight from electronic drawing file (such as a PDF and DOC files). We also provide our customers with on-going technical advice and support. Company History Rilson has been manufacturing custom gaskets and seals since 2007. Our gaskets have been used in well known buildings, famous works of art, and prototype space vehicles.

Gasket Manufacturer & Material Supplier We are an international manufacturer of gaskets and seals, supplying into many industries and countries all over the world. We have a wide experience of working with many different companies, and of making gaskets and seals for a wide variety of conditions and environments. Why do companies buy from us? Specialist: We have expert knowledge of gaskets and seals. Technology: We use the latest gasket materials and manufacturing technology. Design: We offer part-prototyping and samples. Quality: We hold ISO quality certification (ISO 9001). Accountability: We offer full gasket and material traceability. Strong Customer Relationships: We have a reputation for strong customer relationships. International Strengths Order Quantities: No minimum order quantities. Flexibility: All parts are made to order. We can react to changes in demand. Lead Times: Competitive lead times on international orders. Shipping: International shipping by air or sea. Services We work with our customers to make sure that they design and receive the most economical part, which meets their requirements and specifications. We can manufacture from sample, technical drawing, or straight from electronic drawing file (such as a PDF and DOC files). We also provide our customers with on-going technical advice and support. Company History Rilson has been manufacturing custom gaskets and seals since 2007. Our gaskets have been used in well known buildings, famous works of art, and prototype space vehicles.  Packing Detail

Packing Detail

More interests please kindly send me an email or directly contact my Trademanager and I will reply as soon as possible. My email: sales02 at rilson.com.cn Your success is my business.

More interests please kindly send me an email or directly contact my Trademanager and I will reply as soon as possible. My email: sales02 at rilson.com.cn Your success is my business.

Supplier Information

Ningbo Rilson Sealing Material Co., Ltd.

[ Zhejiang China ]

- Business Type : Manufacturer , Trade Company

- Product/Service : Spiral Wound Gasket , Ring Joint Gasket , Kammprofile Gasket

- Tel : 86-574-63119187

More > Other products from this company