Ningbo Rilson Sealing Material Co., Ltd.

Basic Information

- Model No.: RS1

- Packaging: Carton, Wooden case, Plastic Strip

- Delivery Time: 7 Days

- Place of Origin: China (Mainland)

- Brand: Rilson

Specifications 1-sealing under heavy operating conditions

2-strong stress compensation

3-stable and reliable sealing performance

Why choose us? 1)world class gasket

2)standard/no standard gasket

3)genuine products with excellent quality

4)after sales service and technical assistance:

Rilson provide after sales service as the customer's requirement and needs.

5)quick delivery:

Rilson provides just-in-time delivery with its steamlined supply chain.

6)less cost of purchase:

Rilson is a direct importer and agent of manufacturers around global, so there are no intermediary costs involved. If you are interested in our products, please feel free to contact me in Email and I will reply to you as soon as possible. My Email: sales02 at rilson.com.cn Your Success is my business.

2-strong stress compensation

3-stable and reliable sealing performance

| Description | |

| Normal Pressure | 150# to 2500# |

| Normal Diameter | 1/2'' to 60'' |

| Usage | Flat and raised faced diameter flanges up to and inclusive of Class 2500. |

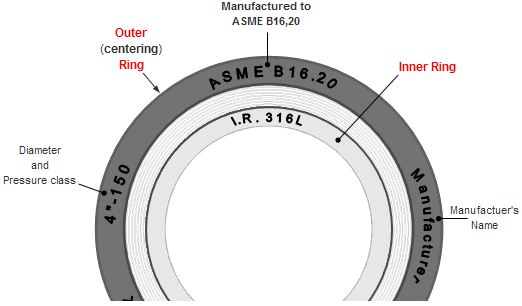

| Applicable Standards | ASME B16.20, BS, JIS, DIN, Suited for ASME B16.47 series A/B flanges |

| Hoop material | ss304, ss316L, 321, 317(L), Monel,Ti, Ni, INC, C/B Zr702, etc. |

| Filler | Graphite, PTFE, Non-asbestos, Mics, Monel, etc. |

| Inner & outer ring material | CS, ss304, ss316L, 321, 317(L), Monel,Ti, Ni, INC, Hast.C/B Zr702,etc. |

| Metallic strip | The standard thickness of the metallic strip is 0.2 mm. |

| Filler | Filler is normally used for thickness from 0.5 mm to 0.6 mm. |

| Centering ring | The centering ring does not come into direct contact with contained fluid. It is normally made of carbon steel and electro plated or painted to avoid corrosion. Other materials are available on request. |

| Inner ring | Inner ring is used to avoid excessive compression due to high seating stress in high-pressure service and it is also used to reduce turbulence in the flange area. It is normally made of the same material as the gasket metallic srtip. |

| Characteristics | A spiral wound gasket able to compress and seal under various loads and provide sealing capabilities. The gasket generally includes a spiral wound portion and an outer guide ring to limit the compression of the gasket. The spiral winding is formed of interdisposed windings of a metal and an elastomer sealant. The metal winding has a non-planar cross-section to inhibit buckling under compression. The gasket is dimensioned such that the elastomer sealant winding has a width greater than the width of the metal winding which has a width greater than the thickness of the guide ring. In this manner, the sealant is compressed before compression of the metal winding which can be compressed until the outer guide ring is encountered |

| Work Shop |

|

|

| Technical Benefits | Metallic winding suited for cyclic loading |

| Outer ring center gasket | |

| Inner/outer ring provides additional blow-out strength | |

| Inner/outer ring provides a compression stop | |

| Prevents flange erosion | |

| Prevents inward buckling | |

| Reduces turbulent flow | |

| Recommended for high pressure/temperature applications |

| Type Style Flange For example | |

| Basic type RS1-R Tongue/Groove 304+F. G | SWG with inner ring RS1-RIR Male&Female 304/304+F. G |

|  |

| SWG with outer ring RS1-CG Raised/Flat face 304+ABS/CS | SWG with inner&outer ring RS1-CGI as above 304/304+F. G/CS |

|  |

| Packaging |

| wooden case, plastic strip, carton box |

|

|

| Production Machinery: | ||||

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

| Cutting Machine | No Information | 3 | 5 | Acceptable |

| Laser Cutting Machine | MESSER | 1 | 2 | Acceptable |

| Shearing Machine | Q11Y-6*25 | 1 | 6 | Acceptable |

| Punching Machine | JH21-125, JD23-25 | 6 | 3 | Acceptable |

| Instrument Machine Tools | SHENHUO & C0650 | 13 | 7 | Acceptable |

| Slot Milling Machine | No Information | 6 | 4 | Acceptable |

| Bending Machine | No Information | 7 | 1 | Acceptable |

| Winding Machine | FEIXIANG & PX500B | 11 | 5 | Acceptable |

| Automatic Winding Machine | No Information | 4 | 1 | Acceptable |

| Laser Printing Machine | TIANHONG | 2 | 2 | Acceptable |

Testing Machinery: | ||||

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

| Universal Testing Machine | GRANDTRY & WA-E | 1 | 3 | Acceptable |

| Certification: | |||||

| Certified Picture | Certification Name | Certified By | Certificate No. | Product Name & Model No. | Available Date --- Expired Date |

| ISO 9001:2008 | CQM, CNAS | CN-00212Q13397R0S | Scope: Production of Metal Winding Gasket, Metal Ring Gasket, Tooth From Gasket, Coating Gasket, Non-Graphite and Graphite Enhanced Gasket | 2012/06/29 --- 2015/06/28 |

| Special Equipment Type Test Certificate | National Quality Supervision & Inspection Center of Sealing Product | TSX 71002520100040 | Flexible Graphite Spiral Wound Gasket (With Inside and Outside Ring) | 2010/03/31 --- 2049/12/31 |

| Special Equipment Type Test Certificate | Special Equipment Type Test Certificate | TSX 71002520100039 | Flexible Graphite Spiral Wound Gasket (Ordinary Type) | 2010/03/31 --- 2049/12/31 |

2)standard/no standard gasket

3)genuine products with excellent quality

4)after sales service and technical assistance:

Rilson provide after sales service as the customer's requirement and needs.

5)quick delivery:

Rilson provides just-in-time delivery with its steamlined supply chain.

6)less cost of purchase:

Rilson is a direct importer and agent of manufacturers around global, so there are no intermediary costs involved. If you are interested in our products, please feel free to contact me in Email and I will reply to you as soon as possible. My Email: sales02 at rilson.com.cn Your Success is my business.

Supplier Information

Ningbo Rilson Sealing Material Co., Ltd.

[ Zhejiang China ]

- Business Type : Manufacturer , Trade Company

- Product/Service : Spiral Wound Gasket , Ring Joint Gasket , Kammprofile Gasket

- Tel : 86-574-63119187

More > Other products from this company