Ningbo Rilson Sealing Material Co., Ltd.

Basic Information

- Model No.: RS1-5001

- Packaging: wooden case, plastic strip, carton box

- Delivery Time: 15 Days

- Place of Origin: Zhejiang, China (Mainland)

- Brand: Rilson

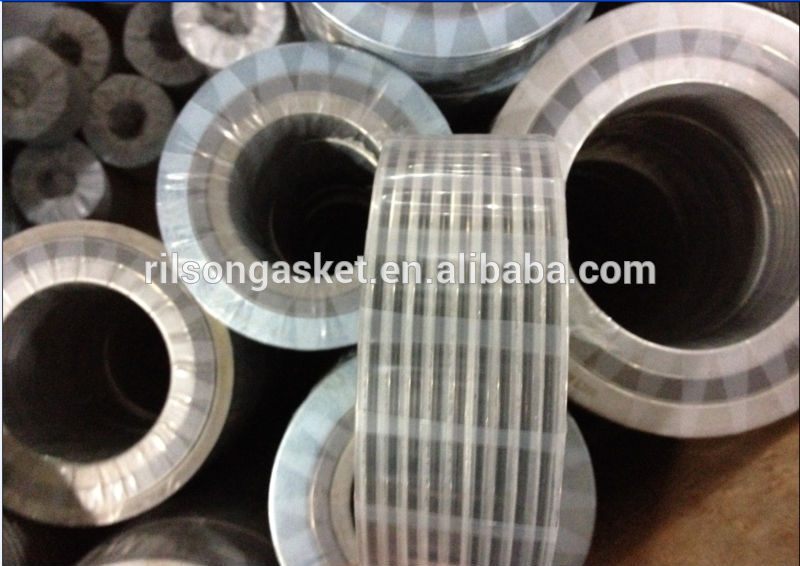

Specifications sealing under heavy operating conditions

strong stress compensation, stable and reliable sealing performance

easy installation

Available in a full range of styles and materials, our spiral wound gaskets are manufactured in accordance with ASME B16.20 for use in all industry flanges, including ASME/ANSI B16.5, ASME B 16.47, Series A & B. American Seal & Packing assures strict adherence to these specifications as routine inspection procedures are applied throughout the manufacturing process. In addition, we maintain trace ability of all materials used in our gasket construction to provide material certifications as required.

Normal Pressure: from 150# to 2500#

Normal Diameter: from 1/2'' to 60''

Usage: Flat and raised faced diameter flanges up to and inclusive of Class 2500. Technical Benefits: >Metallic winding suited for cyclic loading

Technical Benefits: >Metallic winding suited for cyclic loading

>Outer ring center gasket

>Inner/outer ring provides additional blow-out strength

>Inner/outer ring provides a compression stop

>Prevents flange erosion

>Prevents inward buckling

>Reduces turbulent flow

>Recommended for high pressure/temperature applications

Applicable Standards: >ASME B16.20

>BS, JIS,DIN

>Suited for ASME B16.47 series A/B flanges

Construction

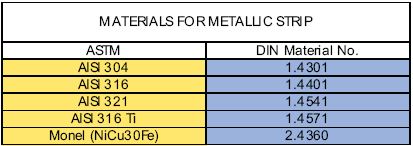

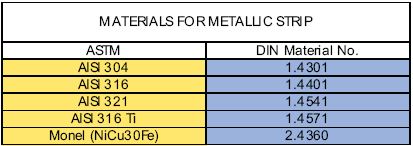

Metallic Strip

The standard thickness of the metallic strip is 0.2 mm.

Filler

Filler is normally used for thickness from 0.5 mm to 0.6 mm.

- Flexible graphite

- PTFE

- Ceramic

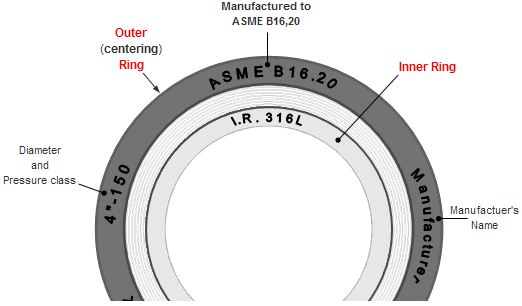

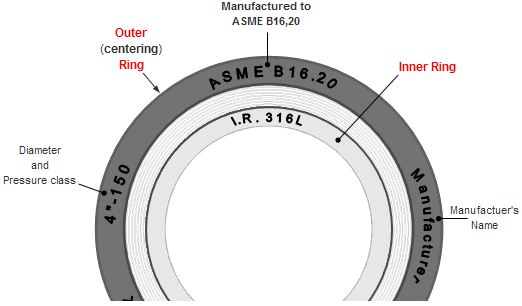

Centering ring

The centering ring does not come into direct contact with contained fluid. It is normally made of carbon steel and electro plated or painted to avoid corrosion. Other materials are available on request.

Inner ring

Inner ring is used to avoid excessive compression due to high seating stress in high-pressure service and it is also used to reduce turbulence in the flange area. It is normally made of the same material as the gasket metallic srtip.

Dimensions

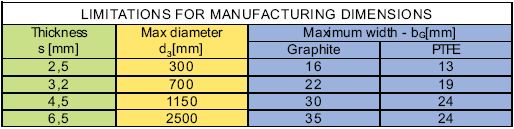

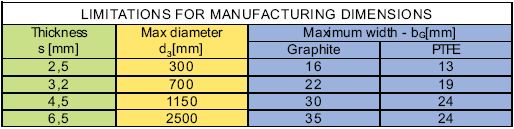

Manufaturing sizes

This limitations are general and can vary according to the special customer.

Thickness

Thickness

The standard manufacturing thickness for spiral wound gaskets are: 3.2 mm; 4.5 mm; 6.5 mm (measured across metallic strip not including the filler, which protrudes slightly beyond the metal).

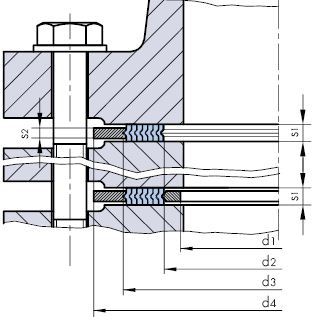

Manufacturing tolerances

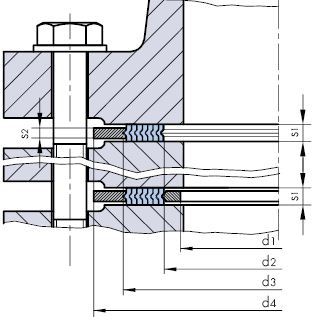

The tolerance of the gasket diameters (d1, d2, d3, d4, s, s1) are stipulated by ASME B 16.20 and DIN 2632-2638 standards. The gaskets designed for non-standard flanges meet the recommendations by the ASME B 16.20.

Dimensions

The dimensions of the standard SWG meet the ASME, BS and EN (DIN) standards. Production Flow Shearing==>Punching==>Lathing==>Drilling==>Assembling==>Packaging Work Shop Packing Details

Packing Details

If you are interested in our products, please contact me! I will reply to you as soon as possible. My target of service is to satisfy your requirements My Email: sales02 at rilson.com.cn

If you are interested in our products, please contact me! I will reply to you as soon as possible. My target of service is to satisfy your requirements My Email: sales02 at rilson.com.cn

strong stress compensation, stable and reliable sealing performance

easy installation

Available in a full range of styles and materials, our spiral wound gaskets are manufactured in accordance with ASME B16.20 for use in all industry flanges, including ASME/ANSI B16.5, ASME B 16.47, Series A & B. American Seal & Packing assures strict adherence to these specifications as routine inspection procedures are applied throughout the manufacturing process. In addition, we maintain trace ability of all materials used in our gasket construction to provide material certifications as required.

Normal Pressure: from 150# to 2500#

Normal Diameter: from 1/2'' to 60''

Usage: Flat and raised faced diameter flanges up to and inclusive of Class 2500.

Technical Benefits: >Metallic winding suited for cyclic loading

Technical Benefits: >Metallic winding suited for cyclic loading>Outer ring center gasket

>Inner/outer ring provides additional blow-out strength

>Inner/outer ring provides a compression stop

>Prevents flange erosion

>Prevents inward buckling

>Reduces turbulent flow

>Recommended for high pressure/temperature applications

Applicable Standards: >ASME B16.20

>BS, JIS,DIN

>Suited for ASME B16.47 series A/B flanges

Construction

| Style | Structure | Hoop material | Filler | Inner & outer ring material |

| SWG | With inner & outer rings | 304(L),316(L),321,317(L), 31803,Monel,Ti,Ni,INC, Hast. C/B Zr702,Etc. | Graphite,PTFE, Asbestos,Non-asbestos, Mics,Monel,etc. | CS,304(L),316(L),321,317(L), 31803,Monel,Ti,Ni,INC, Hast.C/B Zr702,Etc. |

The standard thickness of the metallic strip is 0.2 mm.

Filler

Filler is normally used for thickness from 0.5 mm to 0.6 mm.

- Flexible graphite

- PTFE

- Ceramic

Centering ring

The centering ring does not come into direct contact with contained fluid. It is normally made of carbon steel and electro plated or painted to avoid corrosion. Other materials are available on request.

Inner ring

Inner ring is used to avoid excessive compression due to high seating stress in high-pressure service and it is also used to reduce turbulence in the flange area. It is normally made of the same material as the gasket metallic srtip.

Dimensions

Manufaturing sizes

This limitations are general and can vary according to the special customer.

Thickness

ThicknessThe standard manufacturing thickness for spiral wound gaskets are: 3.2 mm; 4.5 mm; 6.5 mm (measured across metallic strip not including the filler, which protrudes slightly beyond the metal).

Manufacturing tolerances

The tolerance of the gasket diameters (d1, d2, d3, d4, s, s1) are stipulated by ASME B 16.20 and DIN 2632-2638 standards. The gaskets designed for non-standard flanges meet the recommendations by the ASME B 16.20.

Dimensions

The dimensions of the standard SWG meet the ASME, BS and EN (DIN) standards. Production Flow Shearing==>Punching==>Lathing==>Drilling==>Assembling==>Packaging Work Shop

Packing Details

Packing Details

If you are interested in our products, please contact me! I will reply to you as soon as possible. My target of service is to satisfy your requirements My Email: sales02 at rilson.com.cn

If you are interested in our products, please contact me! I will reply to you as soon as possible. My target of service is to satisfy your requirements My Email: sales02 at rilson.com.cn

Supplier Information

Ningbo Rilson Sealing Material Co., Ltd.

[ Zhejiang China ]

- Business Type : Manufacturer , Trade Company

- Product/Service : Spiral Wound Gasket , Ring Joint Gasket , Kammprofile Gasket

- Tel : 86-574-63119187

More > Other products from this company