Hangzhou Jingjing Machinery Co., Ltd.

Basic Information

- Model No.: YT-32-153 & YR-25-158

- Min. Order: 1 Set/Sets

- Payment Type: L/C,T/T

- Delivery Time: 50 Days

- Place of Origin: Zhejiang, China (Mainland)

- Brand: Jingjing Machinery

- Supply Ability: 10 Set/Sets per Year

Specifications smaller space, fewer workers, lower freight, power saving, etc.

Packaging & Shipping 1.Important Components Wiped Anti Rust Oil, Rollers and Shafters covered by foam film. Hydraulic station, PLC control Box, Spare parts and some small parts packed in plywood box. All Components Fixed by steel wire with Container. 2. Delivery Detail: 50 days Product Description 1. Double metal roof panel roll forming machine can fabricate two different roofing sheet 2. 10 years experience 3. CE and ISO certificate passed Corrugated metal roof panel machine Product Feature: The metal roofing sheet produced by roll forming machine look beautiful, elegant and noble. They are widely used for garden, factory, hotel, exhibition center and villa, etc. Corrugated Metal roof panel roll forming machine Components: Roll forming machine consists of Uncoiler, Coil sheet guiding device, Main roll forming system, Post cutting device, Hydraulic station, PLC control system and Auto stacker (or Support table). Optional with Hydraulic Decoiler, Auto Stacker, Safe Cover, Pre-Cutting, Film Covering Device, and so on. Corrugated Metal roof panel roll forming machine Working Flow: Decoiling→Feeding & Guiding→Pre-Cutting(If needed)→Roll Forming→Post Cutting→Finished Products To Support Table

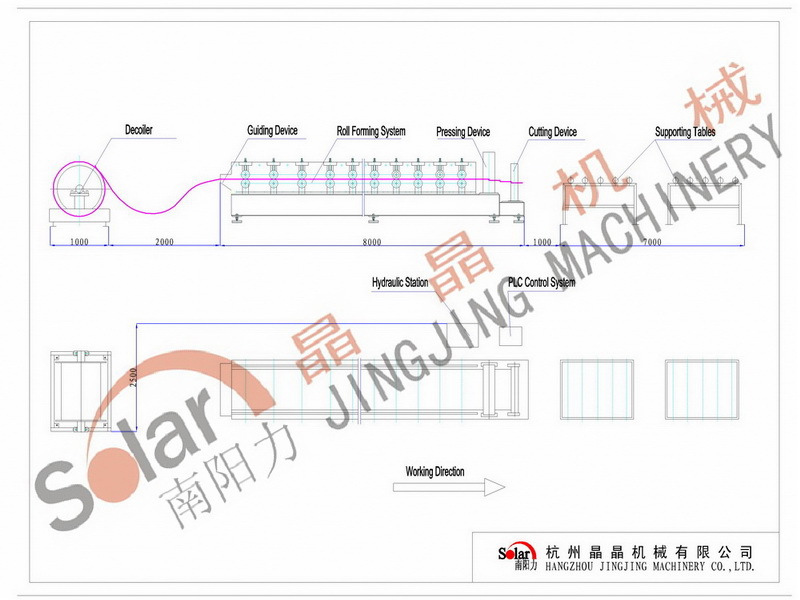

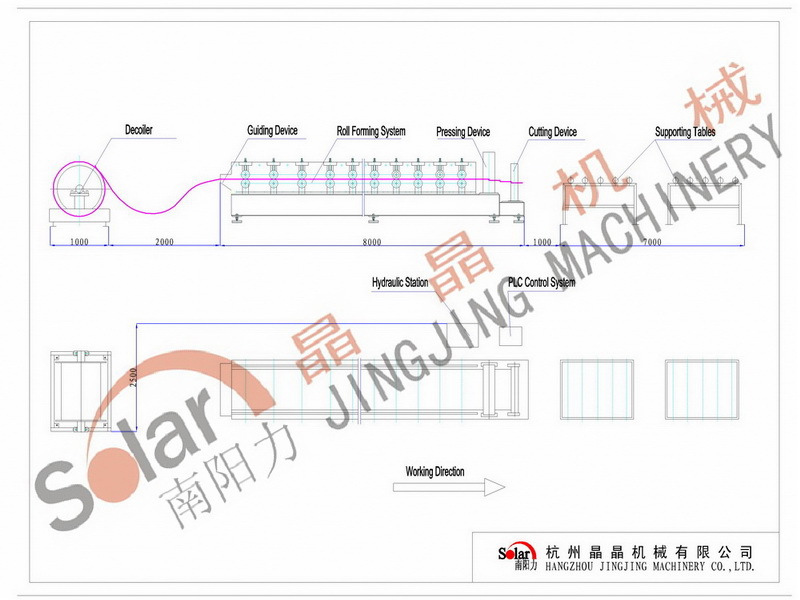

Product Description 1. Double metal roof panel roll forming machine can fabricate two different roofing sheet 2. 10 years experience 3. CE and ISO certificate passed Corrugated metal roof panel machine Product Feature: The metal roofing sheet produced by roll forming machine look beautiful, elegant and noble. They are widely used for garden, factory, hotel, exhibition center and villa, etc. Corrugated Metal roof panel roll forming machine Components: Roll forming machine consists of Uncoiler, Coil sheet guiding device, Main roll forming system, Post cutting device, Hydraulic station, PLC control system and Auto stacker (or Support table). Optional with Hydraulic Decoiler, Auto Stacker, Safe Cover, Pre-Cutting, Film Covering Device, and so on. Corrugated Metal roof panel roll forming machine Working Flow: Decoiling→Feeding & Guiding→Pre-Cutting(If needed)→Roll Forming→Post Cutting→Finished Products To Support Table  Corrugated metal roof panel roll forming machine General Technical Specs

Corrugated metal roof panel roll forming machine General Technical Specs

The photos of Double layers metal roof panel roll forming machine Front side  Backside

Backside  Righside

Righside  Overview

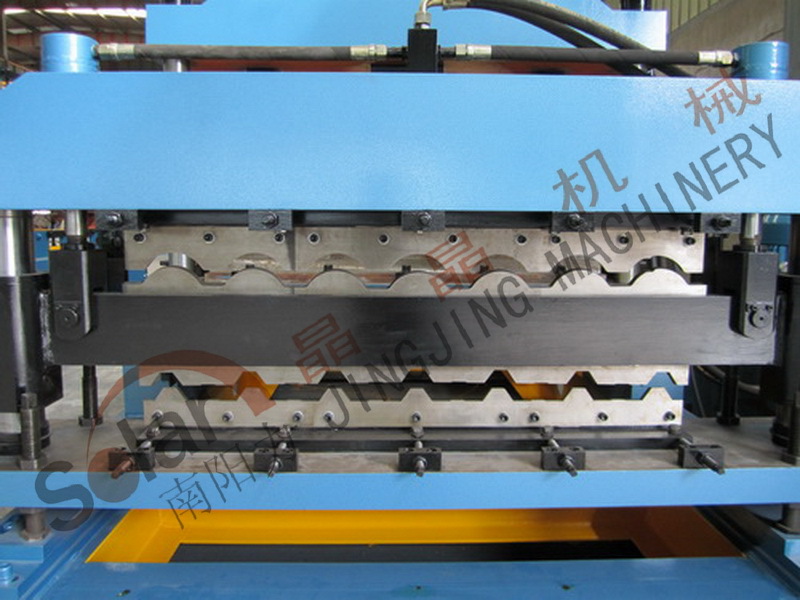

Overview  Detail picture of Double layers metal roof panel roll forming machine

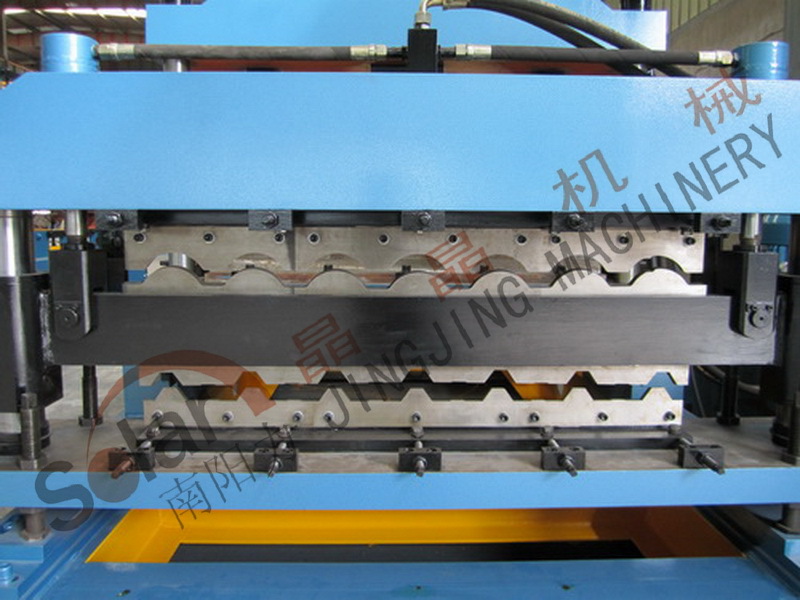

Detail picture of Double layers metal roof panel roll forming machine

Double layers metal roof panel roll forming machine maufacturering process

Double layers metal roof panel roll forming machine maufacturering process

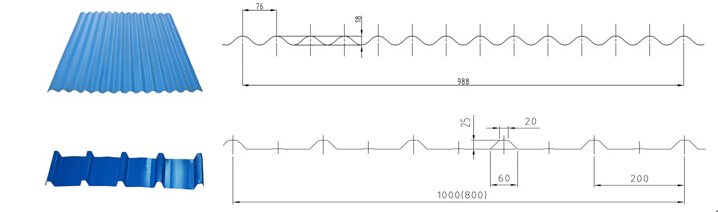

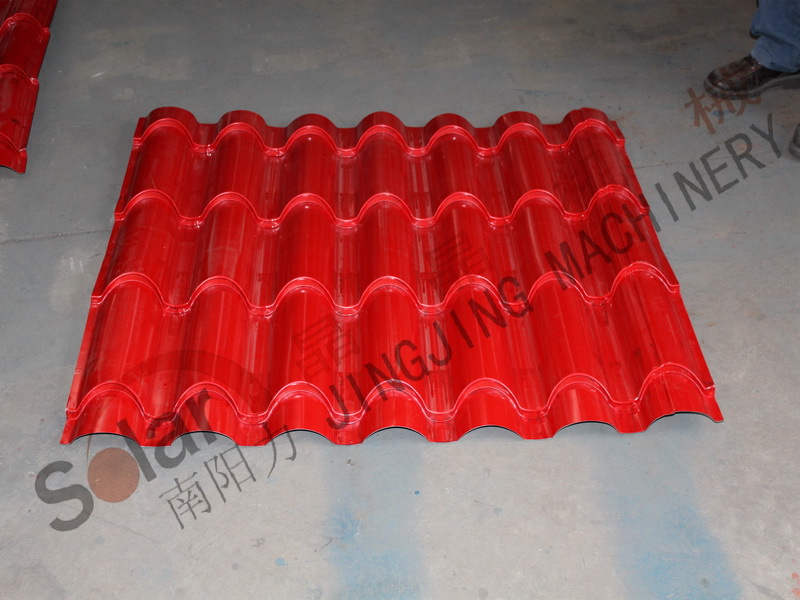

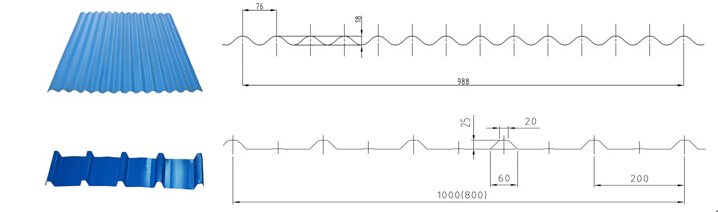

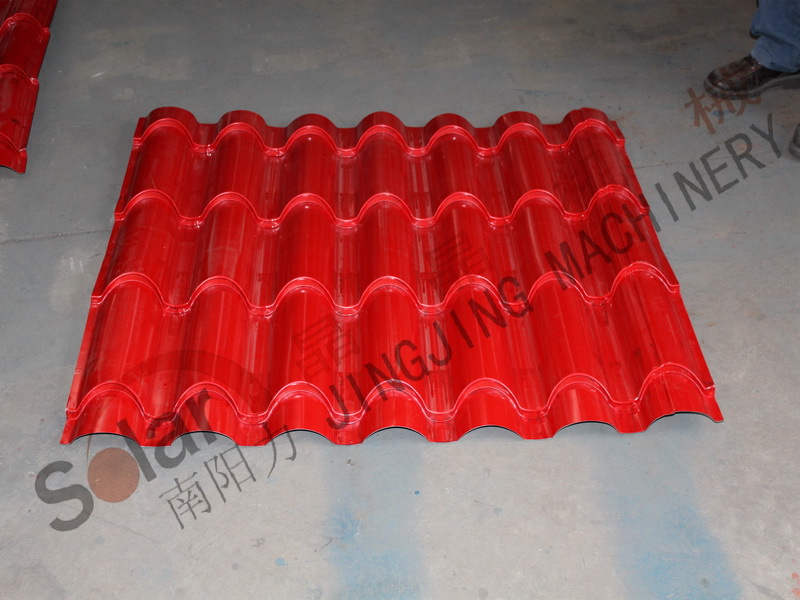

Finished roof tile sample & Popular profiles

Finished roof tile sample & Popular profiles

Overview of the company office

Overview of the company office  Overview of our factory

Overview of our factory  FAQ Question one: How to make a precise quotation ? Answer: In order to offer the sure price to you, firstly, we have to get more detailed imformaiton from you. If you had your own panel profile, we can design the machine according to your profile, and provide you the quotation precisely. If you did not, we can also provide some suggestion to you. In addititon, we need to know the width, thickness and yield strength of the metal material that you want to adopt to. Question two: Can you help us to install the machine in our country? Answer: Sure thing . If you needed, we are pleased to send our engineers and technicians to your company to help you install and test the machine, however you should afford thier fee for transport, hotel and food. If you have any other query about our machines,pls do not hesitate to contact us. If there are any cumtomized machines that you are interested in, Pls feel free to contact us for further discussion. We will provide you most suitable machine solution for your market.

FAQ Question one: How to make a precise quotation ? Answer: In order to offer the sure price to you, firstly, we have to get more detailed imformaiton from you. If you had your own panel profile, we can design the machine according to your profile, and provide you the quotation precisely. If you did not, we can also provide some suggestion to you. In addititon, we need to know the width, thickness and yield strength of the metal material that you want to adopt to. Question two: Can you help us to install the machine in our country? Answer: Sure thing . If you needed, we are pleased to send our engineers and technicians to your company to help you install and test the machine, however you should afford thier fee for transport, hotel and food. If you have any other query about our machines,pls do not hesitate to contact us. If there are any cumtomized machines that you are interested in, Pls feel free to contact us for further discussion. We will provide you most suitable machine solution for your market.

Packaging & Shipping 1.Important Components Wiped Anti Rust Oil, Rollers and Shafters covered by foam film. Hydraulic station, PLC control Box, Spare parts and some small parts packed in plywood box. All Components Fixed by steel wire with Container. 2. Delivery Detail: 50 days

Product Description 1. Double metal roof panel roll forming machine can fabricate two different roofing sheet 2. 10 years experience 3. CE and ISO certificate passed Corrugated metal roof panel machine Product Feature: The metal roofing sheet produced by roll forming machine look beautiful, elegant and noble. They are widely used for garden, factory, hotel, exhibition center and villa, etc. Corrugated Metal roof panel roll forming machine Components: Roll forming machine consists of Uncoiler, Coil sheet guiding device, Main roll forming system, Post cutting device, Hydraulic station, PLC control system and Auto stacker (or Support table). Optional with Hydraulic Decoiler, Auto Stacker, Safe Cover, Pre-Cutting, Film Covering Device, and so on. Corrugated Metal roof panel roll forming machine Working Flow: Decoiling→Feeding & Guiding→Pre-Cutting(If needed)→Roll Forming→Post Cutting→Finished Products To Support Table

Product Description 1. Double metal roof panel roll forming machine can fabricate two different roofing sheet 2. 10 years experience 3. CE and ISO certificate passed Corrugated metal roof panel machine Product Feature: The metal roofing sheet produced by roll forming machine look beautiful, elegant and noble. They are widely used for garden, factory, hotel, exhibition center and villa, etc. Corrugated Metal roof panel roll forming machine Components: Roll forming machine consists of Uncoiler, Coil sheet guiding device, Main roll forming system, Post cutting device, Hydraulic station, PLC control system and Auto stacker (or Support table). Optional with Hydraulic Decoiler, Auto Stacker, Safe Cover, Pre-Cutting, Film Covering Device, and so on. Corrugated Metal roof panel roll forming machine Working Flow: Decoiling→Feeding & Guiding→Pre-Cutting(If needed)→Roll Forming→Post Cutting→Finished Products To Support Table  Corrugated metal roof panel roll forming machine General Technical Specs

Corrugated metal roof panel roll forming machine General Technical Specs | No | Item | Parameter | Note | |

| 1 |

Suitable Material

| Type | Metal Sheet | Customized Specs Acceptable |

| Customized Profile | ||||

| Thickness | 0.3-0.7mm | |||

| Yield Strength | 235MPA | |||

| 2 | Product Specs | Cover width | Customized Profile | |

| Length | Any length | |||

|

3 | Power Specs | Type | 380V/3PH/50HZ | Up to Practical Profile |

| Main Motor | 3-48KW | |||

| Hydraulic | 2.2-11KW | |||

| 4 | Machine Specs | Transmission | Chain and Sprocket | Gearbox and Cardan Acceptable |

| Structure | Column Block Or Wall Plate | |||

| Shafter | No.45 steel tempered | |||

| Rollers | No.45 steel chrome coated | Cr12 or other acceptable | ||

| Cutting Blade | Cr12 quenched | |||

| 5 | Working Capacity | Forming Speed | 15-20m/min for standard solution | Higher Speed Solution Available |

| Working Speed | Up to Length-set Cutting | |||

| 6 | Hydraulic Cantilever Decoiler (Optional) | Type | Hydraulic | |

| Max. Capacity | 5 T/10T/15T | |||

| Suitable coil OD | 1200mm | |||

| Suitable coil ID | 508/610mm | |||

| Max Coil width | 1250mm | |||

| 7 | Forming Stand | 8-48 | Up to Practical Profile | |

| 8 | Forming Shaft Diameter | 55-120mm | Up to Practical Profile | |

| 9 | Type of Cutting | Length-set cutting after roll formed | Pre-cutting acceptable | |

| 10 | Control System | Mitsubishi PLC and Inverter | ||

| 11 | Output Supporter | 2 Pcs Simple Supporter | Auto Stacker Optional | |

Backside

Backside  Righside

Righside  Overview

Overview  Detail picture of Double layers metal roof panel roll forming machine

Detail picture of Double layers metal roof panel roll forming machine

Double layers metal roof panel roll forming machine maufacturering process

Double layers metal roof panel roll forming machine maufacturering process

Finished roof tile sample & Popular profiles

Finished roof tile sample & Popular profiles

Overview of the company office

Overview of the company office  Overview of our factory

Overview of our factory  FAQ Question one: How to make a precise quotation ? Answer: In order to offer the sure price to you, firstly, we have to get more detailed imformaiton from you. If you had your own panel profile, we can design the machine according to your profile, and provide you the quotation precisely. If you did not, we can also provide some suggestion to you. In addititon, we need to know the width, thickness and yield strength of the metal material that you want to adopt to. Question two: Can you help us to install the machine in our country? Answer: Sure thing . If you needed, we are pleased to send our engineers and technicians to your company to help you install and test the machine, however you should afford thier fee for transport, hotel and food. If you have any other query about our machines,pls do not hesitate to contact us. If there are any cumtomized machines that you are interested in, Pls feel free to contact us for further discussion. We will provide you most suitable machine solution for your market.

FAQ Question one: How to make a precise quotation ? Answer: In order to offer the sure price to you, firstly, we have to get more detailed imformaiton from you. If you had your own panel profile, we can design the machine according to your profile, and provide you the quotation precisely. If you did not, we can also provide some suggestion to you. In addititon, we need to know the width, thickness and yield strength of the metal material that you want to adopt to. Question two: Can you help us to install the machine in our country? Answer: Sure thing . If you needed, we are pleased to send our engineers and technicians to your company to help you install and test the machine, however you should afford thier fee for transport, hotel and food. If you have any other query about our machines,pls do not hesitate to contact us. If there are any cumtomized machines that you are interested in, Pls feel free to contact us for further discussion. We will provide you most suitable machine solution for your market.

Supplier Information

Hangzhou Jingjing Machinery Co., Ltd.

[ Zhejiang China ]

- Business Type : Manufacturer , Trade Company

- Product/Service : Roof panel roll forming machines , Purlin roll forming machines , Double layer roll forming machines

- Tel : 18668002716

More > Other products from this company