Hangzhou Jingjing Machinery Co., Ltd.

Basic Information

- Model No.: YR-LC-36-195

- Min. Order: 1 Set/Sets

- Payment Type: L/C,T/T

- Packaging: Container packing of the line suitable for overseas shipping, Package style: Naked and covered by plastic film, spare parts and some small parts packed in wooden box.

- Delivery Time: 50 Days

- Place of Origin: Yunnan, China (Mainland)

- Brand: Solar

- Supply Ability: 40 Set/Sets per Month

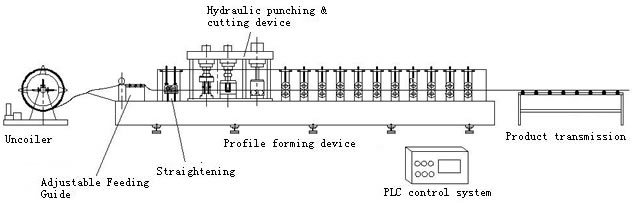

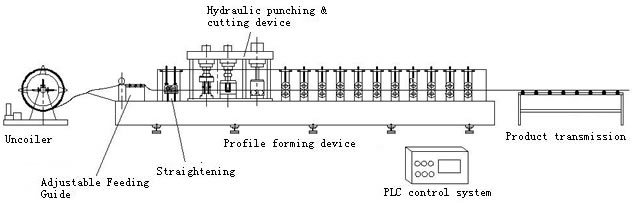

Wall &Roofing Roll Forming Machine components: decoiler, sheet guiding equipment, roll forming section, cutter,supporter, hydraulic system, control system. Technical parameters: Decoiler: umbrella type, passivity decoil, manual expansion Main motor power: 5.5kW Hydraulic motor power: 3kW Hydraulic pump: gear pump CB-E314 Forming stand: 16 stations Working speed: 15M/min Main shaft diameter: Ø76mm Material thicknesses: 0.3-0.8mm Roller materials: high-grade no. 45 forged steel with coated hard 0.05mm chromium Main shaft materials: high-grade no.45 steel by thermal refining Hydraulic station pressure range: 10-12Mpa Blade material: Cr12 by quenching treatment Control system: the production line adopts industry computer PLC frequency converting controller, the length tolerance is ≤2mm Transducer: Mitsubishi PLC: Mitsubishi FX-IS series Equipment: It includes 5T manual decoiler, driver device, main roll former (includes guide device), hydraulic cutter device, hydraulic system, control system (PLC), output table and more Working Flow for Trapezoidal Steel Roof Sheet Roller Machine decoiling the sheet-sheet guiding-roll forming-measure length-cutting the panel-panels to the supporter process of the roll forming machine

the detail of the machine

the detail of the machine

Service Thanks for your visit to Roll Forming Machinery Company.As the professional roof tile forming machines manufacturer based in China ,we mainly produce and market roof tile roll forming machines,double level forming machines ,window frame roll forming machines,floor deck forming machines,guardrail forming machines,steel pipe welding lines,H beam welding line,slitting lines,stacker and filming machines,and so on .

Service Thanks for your visit to Roll Forming Machinery Company.As the professional roof tile forming machines manufacturer based in China ,we mainly produce and market roof tile roll forming machines,double level forming machines ,window frame roll forming machines,floor deck forming machines,guardrail forming machines,steel pipe welding lines,H beam welding line,slitting lines,stacker and filming machines,and so on .

the detail of the machine

the detail of the machine

Service Thanks for your visit to Roll Forming Machinery Company.As the professional roof tile forming machines manufacturer based in China ,we mainly produce and market roof tile roll forming machines,double level forming machines ,window frame roll forming machines,floor deck forming machines,guardrail forming machines,steel pipe welding lines,H beam welding line,slitting lines,stacker and filming machines,and so on .

Service Thanks for your visit to Roll Forming Machinery Company.As the professional roof tile forming machines manufacturer based in China ,we mainly produce and market roof tile roll forming machines,double level forming machines ,window frame roll forming machines,floor deck forming machines,guardrail forming machines,steel pipe welding lines,H beam welding line,slitting lines,stacker and filming machines,and so on .

Supplier Information

Hangzhou Jingjing Machinery Co., Ltd.

[ Zhejiang China ]

- Business Type : Manufacturer , Trade Company

- Product/Service : Roof panel roll forming machines , Purlin roll forming machines , Double layer roll forming machines

- Tel : 18668002716

More > Other products from this company