Hangzhou Huashengtong Machinery Equipment Co., Ltd.

Basic Information

- Model No.: HST-garnet

- Packaging: 25kg/bag

- Delivery Time: 10 Days

- Place of Origin: Zhejiang, China (Mainland)

- Brand: HST

Specifications Garnet abrasive for waterjet cutting

size:20/40 30/60 80 120 150mesh

package:25kg/bag

40bags/bulk bag

Garnet abrasive for waterjet cutting

Main applications of Garnet and Jadeblast are including as follows:

(1)Blast cleaning of steel structure, hull and bridge;

(2)Waterjet cutting of metal, stone and glass;

(3)Filter medium of chemical industry, petroleum, pharmacy and water treatment;

(4)Grinding of marble, optical lens, glassware, leather and other materials;

(5)Raw material of grinding wheel, oil stone, emery cloth and abrasive paper;

(6)Wear-resistant material of expressway pavement, runway, wear-resistant rubber and anti-skid paint.

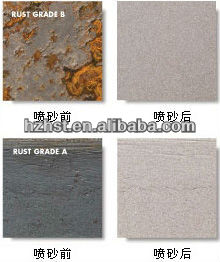

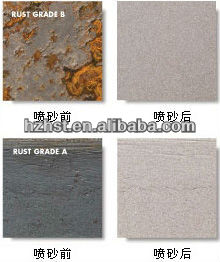

Garnet blasting before and after

Garnet blasting before and after

size:20/40 30/60 80 120 150mesh

package:25kg/bag

40bags/bulk bag

Garnet abrasive for waterjet cutting

| Garnet offers a choice of grades to match any focusing tube and orifice for any given cutting application. Garnet 80 Mesh: The most popular waterjet cutting abrasive grade used worldwide delivers the optimum balance of cutting speed and precision edge. Garnet 50 or 60 Mesh: Suitable for high speed waterjet cutting, it can in some cases deliver up to a 30% increase in cutting speed but at the expense of a reduced precision edge. Garnet 120 Mesh: For high precision and minimum tolerance edge waterjet cutting requirements. The table states the correct combinations of Garnet grades, focusing tube and orifice dimensions to suit your particular waterjet cutting requirements. |

| Garnet Grade | Focusing Tube | Orifice | |

| Industry Standard Configuration | 80 mesh 300-150 micron | .030 - .040" .762 - 1.02mm | .010 - .014" .330 - .356mm |

| High Speed Cutting | 60 mesh 400-200 micron 50 mesh 600-200 micron | .040" 1.02mm .050" 1.27mm | .014 - .015" .356 - .381mm .016 - .018" .407 - .457mm |

| Precision Edge | 80 mesh 300-150 micron | .030 - .040" .762 - 1.02mm | .010 - .014" .330 - .356mm |

| High Precision Edge | 120 mesh 200-100 micron | .020 - .030" .508 - .762mm | .007 - .010" .178 - .330mm |

| Fine Precision Edge | 200 mesh 50-150 micron | .020 - .030" .508 - .762mm | .007 - .010" .178 - .330mm |

(1)Blast cleaning of steel structure, hull and bridge;

(2)Waterjet cutting of metal, stone and glass;

(3)Filter medium of chemical industry, petroleum, pharmacy and water treatment;

(4)Grinding of marble, optical lens, glassware, leather and other materials;

(5)Raw material of grinding wheel, oil stone, emery cloth and abrasive paper;

(6)Wear-resistant material of expressway pavement, runway, wear-resistant rubber and anti-skid paint.

| Garnet model | Using | Sandblasting effect |

| 20/40mesh 30/60mesh | Carbon steel, manganese steel, stainless steel, alloy metal, glass, ceramic, stone, wood, | Serious corrosion, oxidation, skin, or dirty sand-blasting, surface roughness 50-75,60-95 micron |

| 80mesh 120mesh | Aluminum, stainless steel, alloy metal, glass, ceramic, stone, wood, | Surface roughness only matte effect or need to remove surface rust, mill scale, dirt, etc. |

| 150mesh | The restoration of ancient buildings, metal, glass and ceramic fine polishing, grinding | Do fine sandblasting, mainly used in the surface being sprayed does not destroy the case, to remove the surface dirt; polishing paste / wax can be used to produce |

Garnet blasting before and after

Garnet blasting before and after

Supplier Information

Hangzhou Huashengtong Machinery Equipment Co., Ltd.

[ Zhejiang China ]

- Business Type : Trade Company

- Product/Service : Sandblast Machine , sandblast nozzles , Sand blast nozzle

- Tel : 13868116223

More > Other products from this company