Jiangshan Yuanguang Lighting Co., Ltd.

Basic Information

- Model No.: S11-35kV

- Packaging: Main body in nude , the accessories packing in seaworthy standard wooden case

- Delivery Time: 28 Days

- Place of Origin: Zhejiang, China (Mainland)

- Brand: YUANGUANG

Three-phase Oil-immersed Power Transformer •Introduction To Products The performance of our S9 S10 S11 series 20kV and 35kV three-phase oil-immersed transformer conform to the standard of GB 1094-1996 “Power Transformer “ and GB/T6451-2008 “Technical Parameter and requirements of Three-phase Oil-immersed Power Transformer”. The iron core is made of quality cold –rolled silicon steel sheet , and the coil is made of quality oxygen-free copper, featuring good outlook and safe running . The products are widely used in power transmission and distribution of industrial and agricultural power networks. •Main Function And Features 01) Iron core is made of cold-rolled silicon-steel sheet with high conduction of magnetism and adopts pulling-plank structure, so that its magnetic route is short, losses and noise level is low; 02) Compress wire is adopted for winding so losses are low and have good ability withstand short-circuit; 03) Its active part adopts special pressing method which could ensure reliable axial pressure; 04) The oil tank is bell type with the structure of full folding plate type, having an excellent exterior and easy for maintenance; 05) Adopting capsule-type oil container, it can reduce oil aging to the lowest degree. 06) Amount of local discharged: The apparent discharge amount is less than 80pC under the 1.5 times of rated voltage; 07) Noise: Products of 63MVA and below is lower than 58dB(AN); 08) Power loss: no-load loss is 30% lower than that of IEC standard; 09) Reliability: All in-service product have no damages or oil leakage occurred; 10) Oil tank with various kinds of structure and good appearance. •Coil 1) The high-voltage(HV) coil adopts an interleaved-continuous structure to improve the voltage characteristics under impact voltage and make voltage evenly distributed. All stays and pads are chamfered to keep highly reliable insulation. 2) In the transformer winding there is a zigzag oil guide structure so as to fully cool all areas inside the winding, lower the temperature rise of the winding and the hot points of the winding and prolong the service life of insulation. 3) The HV and MV regulation system are independently provided with voltage-regulating winding to balance the ampere turn of each winding-up, effectively lower the axial electrodynamic force generated at short-circuit of transformer and improve abrupt short-circuit withstanding capacity. 4) The winding adopts radial “0” margin designed, between the core and the paper sleeve of LV winding,and between the LV, HV, voltage-regulating windings, as well as before insertion of stays and shroud plate they are fully dried and tightly matched to ensure extremely good compactness and concentricity of the entire winding. •Core 1) The core is made of high-permeable grain-orientated top quality cold-rolled silicon sheet and the material is cut with advanced Germany Geoge GmbH automatic shear line with the cut burrs controlled within 0.02mm. 2) The silicon sheet fabrication adopts “no-upper yoke-lapped’ technology and all lapped joints of the silicon sheet are 45 full- miters. The laminated core sheets are integrally pressed and adhered with epoxy resin to make the three –leg two-yoke core a strong and flat integral one with good verticality precision, this effectively improves no-load performance and reduces noises. 3) Bracing plates are used as support between coil leg and inner coil. The iron yoke is tied with epoxy resin-impregnated glass fiber band, and the lower section of oil tank is tightened with counter-pressure bolts. The upper iron and the upper section of oil bank are fixed at this locations. Hence the body inside the oil tank can withstand the vibration during transportation without any shifting. •Oil tank and accessories 1) The tank wall adopts wide steel sheet, which will be folded into corrugated structure without splicing , in this way welds are decreased and mechanical strength is enhanced ; meanwhile , the corrugated wall has diverging effect, and thus plays a role in decrease of noise. 2) The routing troughs and control cabinets of the secondary circuit are all made of stainless steel , so the entire transformer has a simple and good looking. 3) All sealing surface use quality sealing material and are precision-machined. 4) On the edge of the tank there are double sealing grooves, and the outer sealing material is used to shade the atmosphere and ultra-ray to protect the inner sealing being damaged, thus at utmost prolonging service life and enhancing reliability of the seal. •Subassembly 1) As we have good cooperation tie with many subassembly manufacturers of famous transformer brands, we are able to provide different subassemblies as per users’ requirements . 2) The whole procedure of manufacture , R&D and sales service are carried out strictly in accordance with international standards and ISO quality management system . Main Technical Parameters for 35kV Level S9, S10, S11 Series three-phase no-load-tap-changing oil-immersed power transformer:

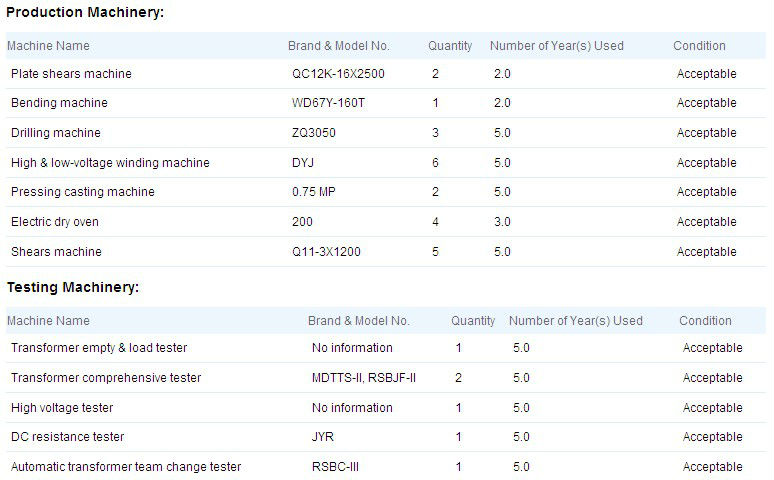

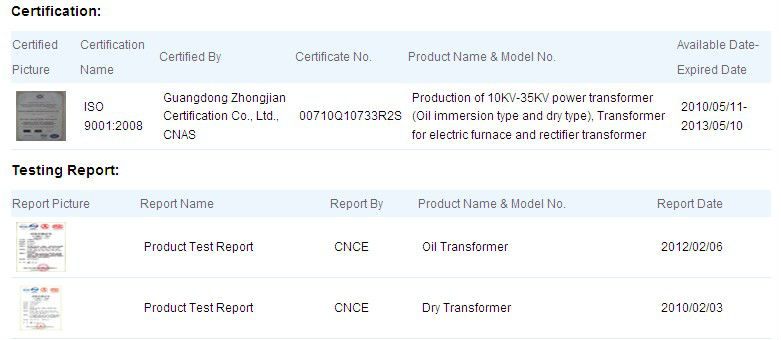

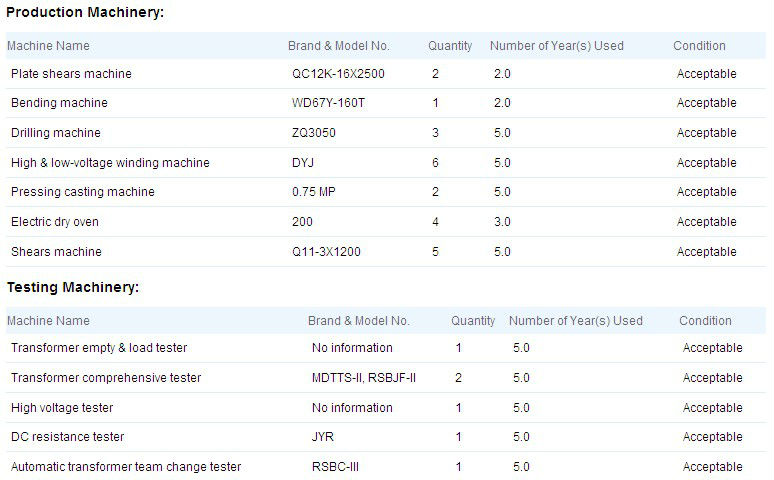

Verified Information

Verified Information

Production Flow

Production Flow

We look forward to cooperating with you , if any inquiries , please contact us freely !

We look forward to cooperating with you , if any inquiries , please contact us freely !  Thank you!

Thank you!

| Rated power (kVA) | High Voltage (kV) | H.V Tap range | Low Voltage (kV) | Connection Symbol | Short-Circuit Impedance (%) | No-load Loss (W) | On-Load Loss (W) | No-load Current (%) | ||||

| 9 Type | 10 Type | 11 Type | 9 Type | 10 Type | 11 Type | |||||||

| 800 | 35 38.5 | ±5% ±2×2.5% | 6.3, 6.6, 10, 10.5 | Yd11 | 12~14 | 1250 | 1110 | 980 | 9900 | 9350 | 9350 | 1.05 |

| 1000 | 1490 | 1320 | 1160 | 12200 | 11500 | 11500 | 1 | |||||

| 1250 | 1760 | 1570 | 1380 | 14650 | 13900 | 13900 | 0.9 | |||||

| 1600 | 2130 | 1900 | 1660 | 17650 | 16600 | 16600 | 0.85 | |||||

| 2000 | 2610 | 2320 | 2030 | 19350 | 18300 | 18300 | 0.75 | |||||

| 2500 | 3150 | 2800 | 2450 | 20700 | 19600 | 19600 | 0.75 | |||||

| 3150 | 7 | 3870 | 3440 | 3010 | 24300 | 23000 | 23000 | 0.7 | ||||

| 4000 | 4640 | 4120 | 3610 | 28800 | 27200 | 27200 | 0.7 | |||||

| 5000 | 5490 | 4880 | 4270 | 33000 | 31200 | 31200 | 0.6 | |||||

| 6300 | 7.5 | 6570 | 5840 | 5110 | 36900 | 34900 | 34900 | 0.6 | ||||

| 8000 | YNd11 | 9000 | 8000 | 7000 | 40500 | 38300 | 38300 | 0.55 | ||||

| 10000 | 10620 | 9440 | 8260 | 47700 | 45100 | 45100 | 0.55 | |||||

| 12500 | 8 | 12600 | 11200 | 10800 | 56700 | 53600 | 53600 | 0.5 | ||||

| 16000 | 15300 | 13600 | 11900 | 69300 | 65500 | 65500 | 0.5 | |||||

| 20000 | 18090 | 16100 | 14100 | 83700 | 79100 | 79100 | 0.5 | |||||

| 25000 | 21510 | 19120 | 16730 | 99000 | 93500 | 93500 | 0.4 | |||||

| 31500 | 25650 | 22800 | 20000 | 118800 | 112200 | 112200 | 0.4 | |||||

Verified Information

Verified Information

Production Flow

Production Flow

We look forward to cooperating with you , if any inquiries , please contact us freely !

We look forward to cooperating with you , if any inquiries , please contact us freely !  Thank you!

Thank you!

Supplier Information

Jiangshan Yuanguang Lighting Co., Ltd.

[ Zhejiang China ]

- Business Type : Manufacturer , Trade Company

- Product/Service : Amorphous alloy transformer , Power transformer , Dry-type transformer

- Tel : 18758968678,15957014504

More > Other products from this company