Shunde Hiseng Glass Machinery Co., Ltd.

- Model No.: SZM

- Packaging: 1.plastics film packed then put on the wooden supporter. 2.suitable package for sea transportation.

- Delivery Time: 60 Days

- Place of Origin: Guangdong, China (Mainland)

- Brand: HSG

Show name: The 27th , 2016 China Glass Exhibition Date: April 11-14, 2016 Hall No.: HALL W4 BOOTH NO.: 046 Place: Shanghai New International Expo Centre (SNIEC) Add: No.2345 Longyang Road, Pudong New Area, Shanghai 201204, China HSD

Show name: The 27th , 2016 China Glass Exhibition Date: April 11-14, 2016 Hall No.: HALL W4 BOOTH NO.: 046 Place: Shanghai New International Expo Centre (SNIEC) Add: No.2345 Longyang Road, Pudong New Area, Shanghai 201204, China HSD HSD series Glass machine double edging line (Glass machine edger line) specialized in grinding parallel double edge of flat glass. Glass is delivered horizontally, crude grinding, refine grinding and polishing are finished in due order. It adopts advanced machine tool moving technology, with PLC control, parallel processing result in high precision and easy operation. a. Technical Specification:

Model | Min.proce ssing size (mm) | Max. proce ssing size (mm) | Thickness of glass (mm) | Speed (m/min) | Total Power (KW) | Weight (kgs) | Measurement (LxWxH) |

HSD 12 | 250X250 | 3000 | 4-25 | 0.5-5 | 26 | 4500 |

|

HSD 16 | 250X250 | 3000 | 4-25 | 0.5-5 | 33 | 5500 | 4.5x4x1.8 |

HSD 18 | 250X250 | 3000 | 4-25 | 0.5-5 | 37 | 6000 | 4.5x4.3x1.8 |

HSD 20 | 300X300 | 3000 | 4-25 | 0.5-5 | 42 | 6500 | 4.5X4.6X1.8 |

HSD 22 | 300X300 | 3000 | 4-25 | 0.5-5 | 45 | 7000 | 4.9X4.5X1.8 |

Model | HSD 12 | HSD 16 | HSD 18 | HSD 20 | HSD 22 |

Wheel No.1 | Diamond wheel with teeth #100/Ø150xØ12x12x8 | Diamond wheel with teeth #100 Ø150xØ12x12x8 | Diamond wheel with teeth #100 Ø150xØ12x12x8 | Diamond wheel with teeth #80 Ø150xØ12x12x8 | Diamond wheel with teeth #80 Ø150xØ12x12x8 |

Wheel No.2 | Resin Wheel #240 Ø150x Ø12x10x10 | Resin Wheel #240 Ø150x Ø12x10x10 | Diamond wheel #240 Ø150xØ12x8x8 | Diamond wheel #150 Ø150xØ12x8x8 | Diamond wheel #150 Ø150xØ12x8x8 |

Wheel No.3 | Diamond wheel #240 Ø130xØ12x8x8 | Diamond wheel #240 Ø130xØ12x8x8 | Diamond wheel #240 Ø130xØ12x8x8 | Diamond wheel #240 Ø150xØ12x8x8 | Diamond wheel #240 Ø150xØ12x8x8 |

Wheel No.4 | Diamond wheel #240 Ø130xØ12x8x8 | Polishing wheel Ø130 Ø60x35 | Polishing wheel Ø130 Ø60x35 | Diamond wheel #240 Ø130xØ12x8x8 | Diamond wheel #240 Ø130xØ12x8x8 |

Wheel No.5 | Polishing Wheel Ø150x Ø60x35 | Diamond wheel #240 Ø130xØ12x8x8 | Diamond wheel #240 Ø130xØ12x8x8 | Polishing wheel Ø130 Ø60x35 | Polishing wheel Ø130 Ø60x35 |

Wheel No.6 | C3 wheel Ø150x Ø70x40 | Polishing wheel Ø130 Ø60x35 | Polishing wheel Ø130 Ø60x35 | Diamond wheel #240 Ø130xØ12x8x8 | Diamond wheel #240 Ø130xØ12x8x8 |

Wheel No.7 |

| Polishing wheel Ø150 Ø70x40 | Resin Wheel #280 Ø150x Ø12x10x10 | Polishing wheel Ø130 Ø60x35 | Polishing wheel Ø130 Ø60x35 |

Wheel No.8 |

| C3 wheel Ø150 Ø70x40 | Polishing wheel Ø150 Ø70x40 | Resin Wheel #280 Ø150x Ø12x8x8 | Resin Wheel #240 Ø150x Ø12x8x8 |

Wheel No.9 |

|

| C3 wheel Ø150 Ø70x40 | Polishing wheel Ø150 Ø70x40 | Polishing wheel Ø150 Ø70x40 |

Wheel No.10 |

|

|

| C3 wheel Ø150 Ø70x40 | Polishing wheel Ø150 Ø70x40 |

Wheel No.11 |

|

|

|

| C3 wheel Ø150 Ø70x40 |

d. HSG Glass machine Special advantage Double edger: 1) Normally, double edger most big problem is water problem, water will be every where on the surface of glass, later, will bring it out to loading and unloading area, also, it can easy to make scratch on surface of glass, also, make dirty of glass surface. Our double edger, when processing, on the surface of glass, there is no any water, this way, make your washing later on very simple, and more efficient.

d. HSG Glass machine Special advantage Double edger: 1) Normally, double edger most big problem is water problem, water will be every where on the surface of glass, later, will bring it out to loading and unloading area, also, it can easy to make scratch on surface of glass, also, make dirty of glass surface. Our double edger, when processing, on the surface of glass, there is no any water, this way, make your washing later on very simple, and more efficient.  2)There is very easy for glass moving not in order when processing, because, left and right side belts turning speed, and upper and bottom belt turning speed is different. So, It will effect working performance, specially polishing result. Our double edger, upper and bottom belt, left and right side belt, is driving by stronger three shaft gearing system, this system, make all belts turns in same speed, in same time. So, glass move inside very smooth. Also, it is very easy for customer to change timming belts. 3)Polishing problem. Most of double edger, polishing result is not so good. Our double edger using special design of slide board, we using cross-bearing slide board, when motor is moving, it will be more smooth, so, polishing result is very shinning and sharp.

2)There is very easy for glass moving not in order when processing, because, left and right side belts turning speed, and upper and bottom belt turning speed is different. So, It will effect working performance, specially polishing result. Our double edger, upper and bottom belt, left and right side belt, is driving by stronger three shaft gearing system, this system, make all belts turns in same speed, in same time. So, glass move inside very smooth. Also, it is very easy for customer to change timming belts. 3)Polishing problem. Most of double edger, polishing result is not so good. Our double edger using special design of slide board, we using cross-bearing slide board, when motor is moving, it will be more smooth, so, polishing result is very shinning and sharp.  4)Now, the trend for glass processing is more thicker and more big size glass sheet. We had special strong basement We had longer fixed and moving bridge to support glass We had special stronger timming belt to delivery glass, bottom timming belt width is 65mm for 3m machine, 100mm for 5 mmachine.

4)Now, the trend for glass processing is more thicker and more big size glass sheet. We had special strong basement We had longer fixed and moving bridge to support glass We had special stronger timming belt to delivery glass, bottom timming belt width is 65mm for 3m machine, 100mm for 5 mmachine.  5)Automatic center supporting system No need to carry by hand when glass change, no need to adjust.

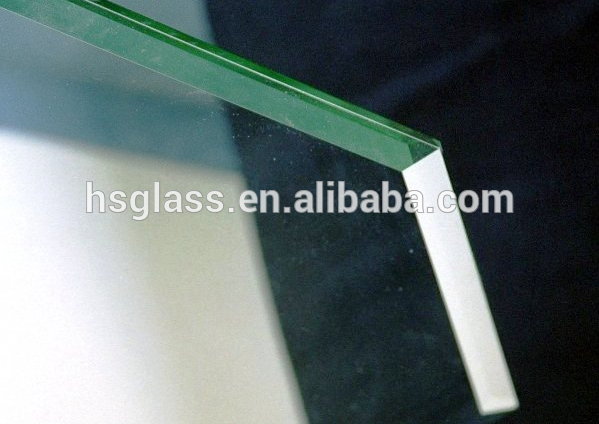

5)Automatic center supporting system No need to carry by hand when glass change, no need to adjust.  6)High sepcificaiton: ABB motor, Siemens PLC Schnider electrical parts d. Finished sample by HSG Glass machine

6)High sepcificaiton: ABB motor, Siemens PLC Schnider electrical parts d. Finished sample by HSG Glass machine  Certifications All Glass machines from Hiseng get CE approval. l Glass Drilling machine: U2010 01 ****** 002 l Glass Edging machine: U2010 01 ****** 005 l Glass Sandblasting machine:US2010 01 ****** 004 l Glass Washing Machine:U2010 01 ****** 001 l Shape Glass Grinding machine: U2010 01 ****** 003 l Glass Straight Line Double Edging machine: 243-CI-***** l Glass straight Line Round Double Edging machine:242-CI-***** l Glass Transferring Table: 241-CI-*****

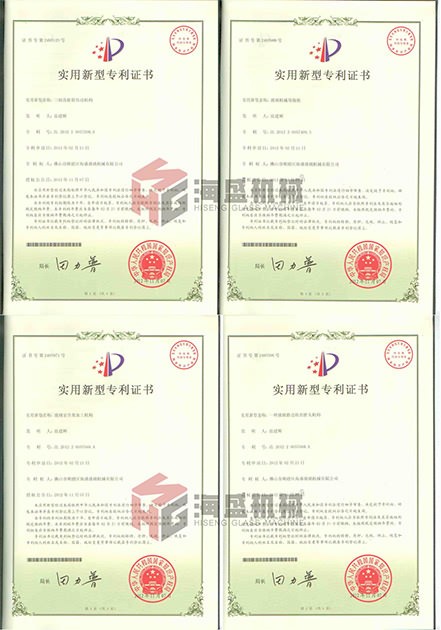

Certifications All Glass machines from Hiseng get CE approval. l Glass Drilling machine: U2010 01 ****** 002 l Glass Edging machine: U2010 01 ****** 005 l Glass Sandblasting machine:US2010 01 ****** 004 l Glass Washing Machine:U2010 01 ****** 001 l Shape Glass Grinding machine: U2010 01 ****** 003 l Glass Straight Line Double Edging machine: 243-CI-***** l Glass straight Line Round Double Edging machine:242-CI-***** l Glass Transferring Table: 241-CI-*****  Hiseng Glass Machinery Co., Owns some Patents. Thanks a lot for the R&D team working hard. Processing device for Glass Safety Corner: Patent # ZL 2012 2 005****.4 New Carriage in Glass machinery : Patent # ZL 2012 2 005****.3 Three shafts Gear Box Driving device: Patent # ZL 2012 2 005****.5 Spindle Device in Glass Machinery: Patent # ZL 2012 2 005****.X

Hiseng Glass Machinery Co., Owns some Patents. Thanks a lot for the R&D team working hard. Processing device for Glass Safety Corner: Patent # ZL 2012 2 005****.4 New Carriage in Glass machinery : Patent # ZL 2012 2 005****.3 Three shafts Gear Box Driving device: Patent # ZL 2012 2 005****.5 Spindle Device in Glass Machinery: Patent # ZL 2012 2 005****.X

e. HSG Glass machine Packing: 1.plastics film packed then put on the wooden supporter.

2.suitable package for sea transportation. f. HSG Glass machines Container loading picture as below:

g. Company information: Believing in doing best, become stronger and power, we were successfully in wide range of machinery in last 6 years: such as architecture glass line, solar glass processing line, glass double edger, round double edger line. Beveller, vertical edger, washer, driller and sand blasting. Our products pass CE certificate, the products were widely sold to USA, Mexico, Brazil, Argentina, Russia, India, Middle East area, Australia, Italy, Spain, Chile, Bolivia, D. Republic, Aruba, Venezuela, Paraguay, Uruguay and so on. Depends on technology innovation, with strict ISO production management, profession QC control system, we ensured our products will become more complete, details, more safe, more accurate and faster in processing speed. To make your work more easy is our target. We were always striving in providing smart and humanized products and service to you. We are focusing in providing flexible customized production line and service to our customer.

g. Company information: Believing in doing best, become stronger and power, we were successfully in wide range of machinery in last 6 years: such as architecture glass line, solar glass processing line, glass double edger, round double edger line. Beveller, vertical edger, washer, driller and sand blasting. Our products pass CE certificate, the products were widely sold to USA, Mexico, Brazil, Argentina, Russia, India, Middle East area, Australia, Italy, Spain, Chile, Bolivia, D. Republic, Aruba, Venezuela, Paraguay, Uruguay and so on. Depends on technology innovation, with strict ISO production management, profession QC control system, we ensured our products will become more complete, details, more safe, more accurate and faster in processing speed. To make your work more easy is our target. We were always striving in providing smart and humanized products and service to you. We are focusing in providing flexible customized production line and service to our customer.  HSG took fairs for Glass machines

HSG took fairs for Glass machines

- Business Type : Manufacturer

- Product/Service : Glass edging machine , Glass beveling machine , Glass washing machine

- Tel : 13922166837