Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

Basic Information

- Model No.: MG

- Packaging: Wooden case

- Delivery Time: 10 Days

- Place of Origin: Hebei, China (Mainland)

- Brand: GS

Company Information Shijiazhuang Gravel Slurry Pump Industry Co.,Ltd is a huge manufacturer of slurry pump, Gravel sand pump, Dredging pump,Chemical pump,Multistage pump,Water pump,Submersible sewage pump and pump spares in North of China. Our variety of pumps are widely used in mining, metallurgy, coal washery, power plant, sewage water treatment, dredging, and chemical and petroleum industries. Product Description Specification: Size (discharge): 4" to 18"

Capacity: 36~ 5800 m3/hr

Head: 6m ~ 135 m

Handing solids: 0 ~ 650mm

Concentration: 0%~ 70%

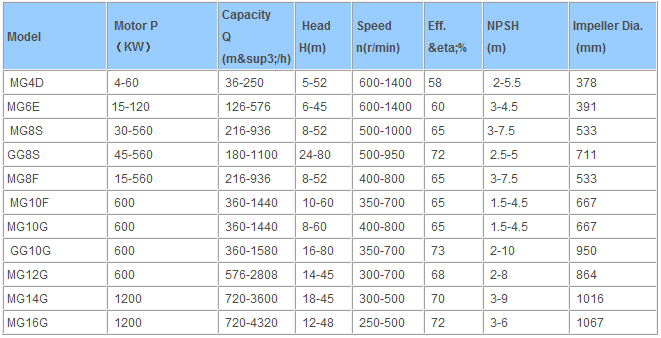

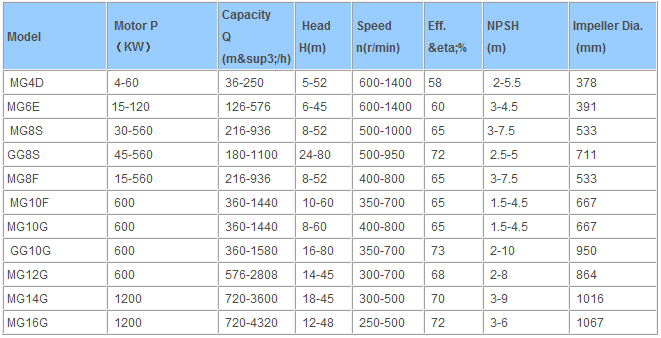

Material: metal:High chrome alloy or Rubber MG Dredge Pump are the most comprehensive range of centrifugal gravel sand pumps for use in mining, chemical and general industry applications. The horizontal sand gravel pumps are designed for heavy duty applications such as mining, power sector,dredging river,and tailings as well as specialty applications, which are used for continuous pumping of high abrasive, high density sand and gravels. Detailed specification: 1. Advanced hydraulic dredging sand pump model, CAD 3D design, high efficiency and obvious energy-saving. 2. Large dredging sand depth, high density of dredging mud, good pump NPSH and strong suction lift ability. 3. Strong through-put. The dredging pump can persistently discharge gravel, high plastic soil lump,etc. 4. The gravel sand pump can be directly matched with either motor or diesel engine. 5. Wide application.The gravel sand pump can be used in various kinds of soil quality. Generally,the dredge sand pump is matched with an impeller with 3 or 5 pieces of vane. At the same time,the impellers can be provided with various diameters and vane types to suit kinds of working conditions. 6. Little hydraulic loss, high efficiency and low oil-consumption. 7. Little volume, light weight. 8. Steady operating, little vibration, low noise. 9. Simple & reliable constrution, easily disassembly & assembly,convenient maintaince. 10. Reliable sealing without leakage. 11. Long operating life of parts MG Dredge Pump Parameter Selection Table: MG Dredge Pump Componet Diagram:

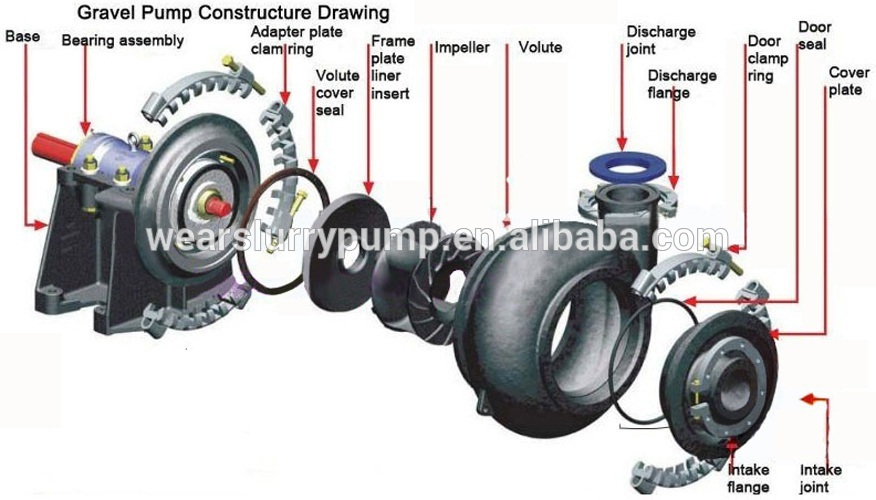

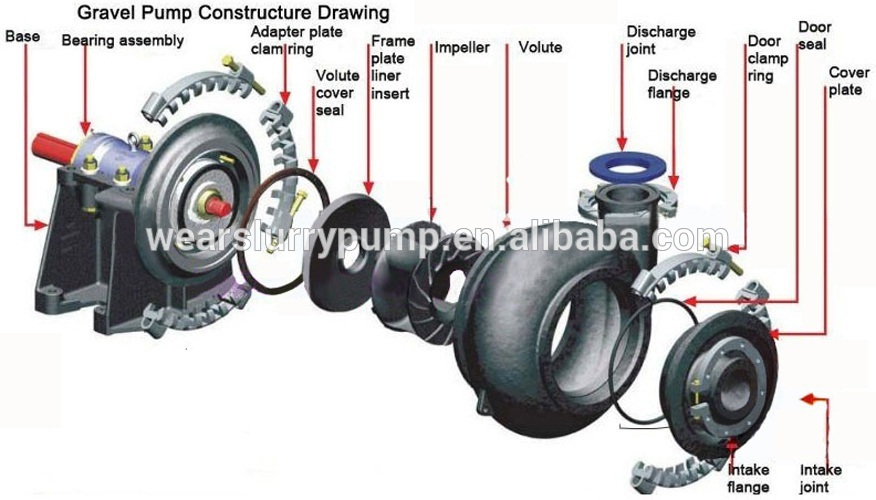

MG Dredge Pump Componet Diagram:

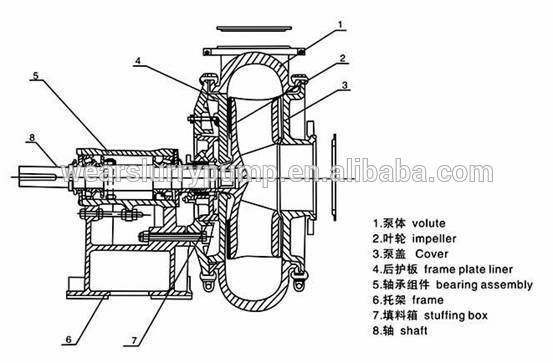

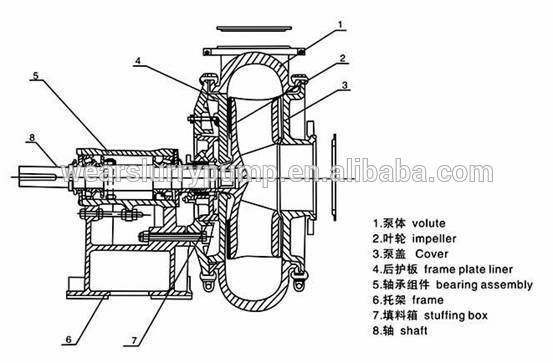

MG Dredge Pump Structural Drawing:

MG Dredge Pump Shaft Seal: Packing Seal :

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal :

MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications. MG Dredge Pump Drive Type:

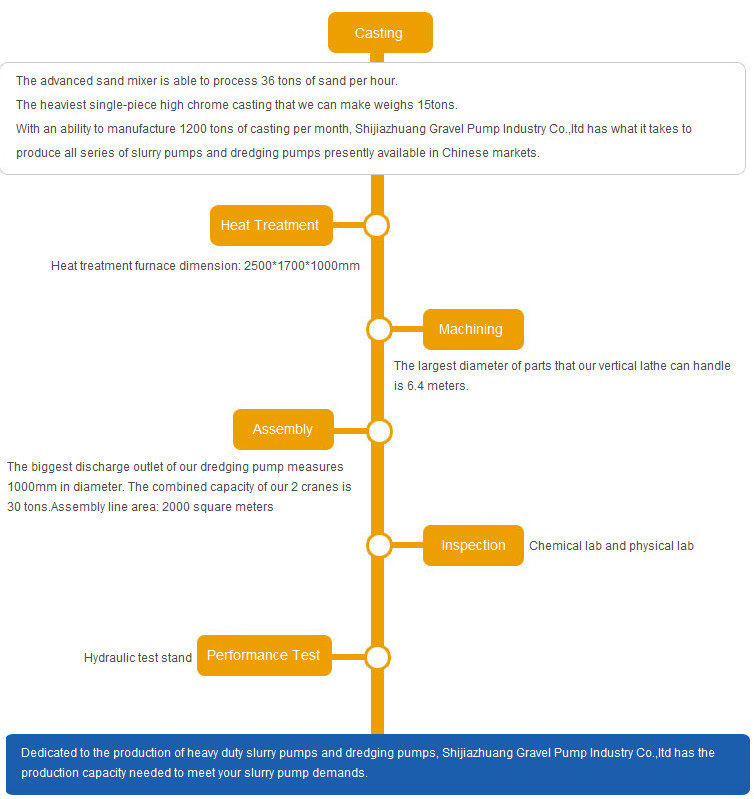

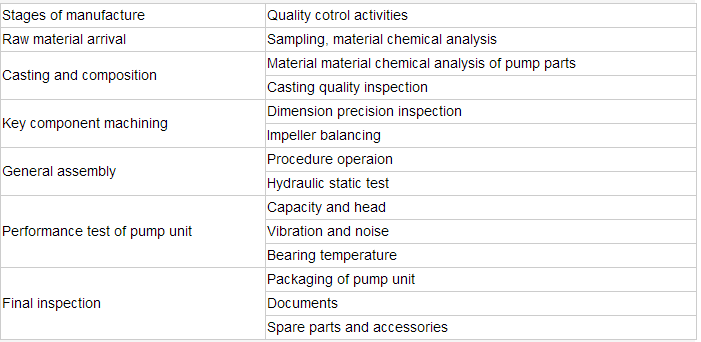

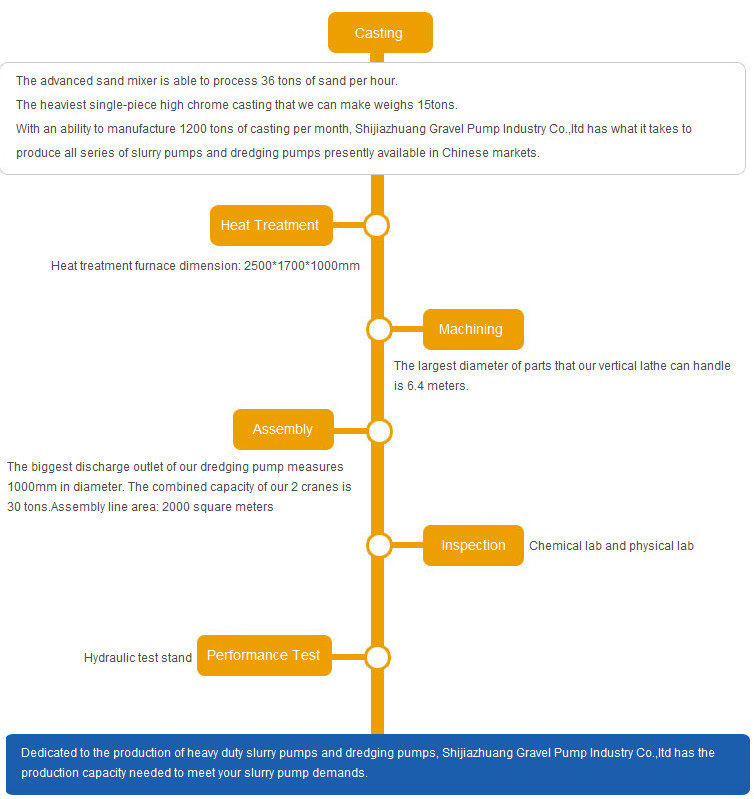

MG Dredge Pump Production process:

Packing & Shipping Testing

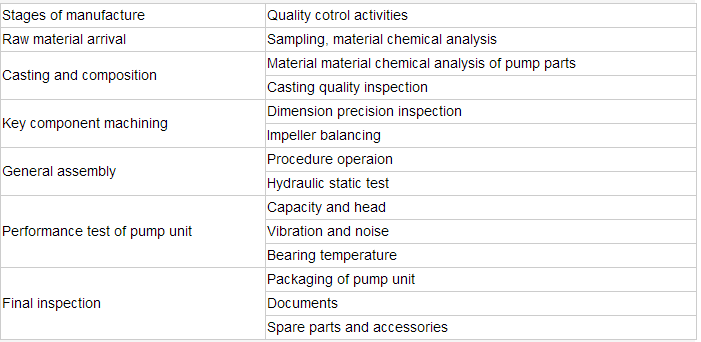

Packing & Shipping Testing  Quality control:

Quality control:  SERVICES AFTER-SALE: As the slurry pump wet ends parts such as the impeller,volute liner,FPL insert,Throat bush are consumption parts and we could provide you always the qualified slurry pump parts within very short time. SERVICES PACKING&TRANSPORT Considering the order pump size and we could provide case or pallet as per your need to make sure it safe enough during the long distance road and ocean shipping.have its own export company and so we could help you find the best ocean shipping solution and service for you from the goods out of factory to your destination. SERVICES INSTALLATION We have more than 20 years experienced pump installation workers and are very aware of any onside application.We could provide abroad pump installation service and expect pump manufacturing and sales,abroad pump installation is getting more and more popular by our regular clients abroad. SERVICES TECHNICAL SUPPORT Performance Chart,Components Diagram,Installation Drawing, our newest E-Catalogue,please feel free to send us a email and we will send you within 24 hours. On-site Application MG Dredge Pump On-site Application:

SERVICES AFTER-SALE: As the slurry pump wet ends parts such as the impeller,volute liner,FPL insert,Throat bush are consumption parts and we could provide you always the qualified slurry pump parts within very short time. SERVICES PACKING&TRANSPORT Considering the order pump size and we could provide case or pallet as per your need to make sure it safe enough during the long distance road and ocean shipping.have its own export company and so we could help you find the best ocean shipping solution and service for you from the goods out of factory to your destination. SERVICES INSTALLATION We have more than 20 years experienced pump installation workers and are very aware of any onside application.We could provide abroad pump installation service and expect pump manufacturing and sales,abroad pump installation is getting more and more popular by our regular clients abroad. SERVICES TECHNICAL SUPPORT Performance Chart,Components Diagram,Installation Drawing, our newest E-Catalogue,please feel free to send us a email and we will send you within 24 hours. On-site Application MG Dredge Pump On-site Application:  Mine:Black, non-ferrous ore slurry material pump and all kinds of concentrate and tailings conveying Metallurgy:Transport various slurry for aluminium or steel manufacture Coal: Coal mining, washing and various coarse and fine coal slurry transportation Electricity:Remove power plant ash,wash ash,various ash dregs or ash slurry transportation Construction materials:Various mud sand slurry(such as Cement slurry) transportation Chemical: Phosphatic fertilizer or potassic fertilizer factory various abrasive slurry trasportation Water conservancy:Lake,river dredge, sediment,grit, High plastic clay Suction line to transportation Pump Spares MG Dredge Pump Spare Parts:

Mine:Black, non-ferrous ore slurry material pump and all kinds of concentrate and tailings conveying Metallurgy:Transport various slurry for aluminium or steel manufacture Coal: Coal mining, washing and various coarse and fine coal slurry transportation Electricity:Remove power plant ash,wash ash,various ash dregs or ash slurry transportation Construction materials:Various mud sand slurry(such as Cement slurry) transportation Chemical: Phosphatic fertilizer or potassic fertilizer factory various abrasive slurry trasportation Water conservancy:Lake,river dredge, sediment,grit, High plastic clay Suction line to transportation Pump Spares MG Dredge Pump Spare Parts:  Our Own Factory

Our Own Factory

Contact Person Bruce Zhang

Contact Person Bruce Zhang

Sales Engineer

Shijiazhuang Gravel Slurry Pump Industry Co.,Ltd

Email: Sales5(at)gsslurrypump.com Skype: Sino.pumps Tel: +86-17603208259 Fax: +86-0311-83050889

Capacity: 36~ 5800 m3/hr

Head: 6m ~ 135 m

Handing solids: 0 ~ 650mm

Concentration: 0%~ 70%

Material: metal:High chrome alloy or Rubber MG Dredge Pump are the most comprehensive range of centrifugal gravel sand pumps for use in mining, chemical and general industry applications. The horizontal sand gravel pumps are designed for heavy duty applications such as mining, power sector,dredging river,and tailings as well as specialty applications, which are used for continuous pumping of high abrasive, high density sand and gravels. Detailed specification: 1. Advanced hydraulic dredging sand pump model, CAD 3D design, high efficiency and obvious energy-saving. 2. Large dredging sand depth, high density of dredging mud, good pump NPSH and strong suction lift ability. 3. Strong through-put. The dredging pump can persistently discharge gravel, high plastic soil lump,etc. 4. The gravel sand pump can be directly matched with either motor or diesel engine. 5. Wide application.The gravel sand pump can be used in various kinds of soil quality. Generally,the dredge sand pump is matched with an impeller with 3 or 5 pieces of vane. At the same time,the impellers can be provided with various diameters and vane types to suit kinds of working conditions. 6. Little hydraulic loss, high efficiency and low oil-consumption. 7. Little volume, light weight. 8. Steady operating, little vibration, low noise. 9. Simple & reliable constrution, easily disassembly & assembly,convenient maintaince. 10. Reliable sealing without leakage. 11. Long operating life of parts MG Dredge Pump Parameter Selection Table:

MG Dredge Pump Componet Diagram:

MG Dredge Pump Componet Diagram:

MG Dredge Pump Structural Drawing:

MG Dredge Pump Shaft Seal: Packing Seal :

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal :

MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications. MG Dredge Pump Drive Type:

MG Dredge Pump Production process:

Packing & Shipping Testing

Packing & Shipping Testing  Quality control:

Quality control:  SERVICES AFTER-SALE: As the slurry pump wet ends parts such as the impeller,volute liner,FPL insert,Throat bush are consumption parts and we could provide you always the qualified slurry pump parts within very short time. SERVICES PACKING&TRANSPORT Considering the order pump size and we could provide case or pallet as per your need to make sure it safe enough during the long distance road and ocean shipping.have its own export company and so we could help you find the best ocean shipping solution and service for you from the goods out of factory to your destination. SERVICES INSTALLATION We have more than 20 years experienced pump installation workers and are very aware of any onside application.We could provide abroad pump installation service and expect pump manufacturing and sales,abroad pump installation is getting more and more popular by our regular clients abroad. SERVICES TECHNICAL SUPPORT Performance Chart,Components Diagram,Installation Drawing, our newest E-Catalogue,please feel free to send us a email and we will send you within 24 hours. On-site Application MG Dredge Pump On-site Application:

SERVICES AFTER-SALE: As the slurry pump wet ends parts such as the impeller,volute liner,FPL insert,Throat bush are consumption parts and we could provide you always the qualified slurry pump parts within very short time. SERVICES PACKING&TRANSPORT Considering the order pump size and we could provide case or pallet as per your need to make sure it safe enough during the long distance road and ocean shipping.have its own export company and so we could help you find the best ocean shipping solution and service for you from the goods out of factory to your destination. SERVICES INSTALLATION We have more than 20 years experienced pump installation workers and are very aware of any onside application.We could provide abroad pump installation service and expect pump manufacturing and sales,abroad pump installation is getting more and more popular by our regular clients abroad. SERVICES TECHNICAL SUPPORT Performance Chart,Components Diagram,Installation Drawing, our newest E-Catalogue,please feel free to send us a email and we will send you within 24 hours. On-site Application MG Dredge Pump On-site Application:  Mine:Black, non-ferrous ore slurry material pump and all kinds of concentrate and tailings conveying Metallurgy:Transport various slurry for aluminium or steel manufacture Coal: Coal mining, washing and various coarse and fine coal slurry transportation Electricity:Remove power plant ash,wash ash,various ash dregs or ash slurry transportation Construction materials:Various mud sand slurry(such as Cement slurry) transportation Chemical: Phosphatic fertilizer or potassic fertilizer factory various abrasive slurry trasportation Water conservancy:Lake,river dredge, sediment,grit, High plastic clay Suction line to transportation Pump Spares MG Dredge Pump Spare Parts:

Mine:Black, non-ferrous ore slurry material pump and all kinds of concentrate and tailings conveying Metallurgy:Transport various slurry for aluminium or steel manufacture Coal: Coal mining, washing and various coarse and fine coal slurry transportation Electricity:Remove power plant ash,wash ash,various ash dregs or ash slurry transportation Construction materials:Various mud sand slurry(such as Cement slurry) transportation Chemical: Phosphatic fertilizer or potassic fertilizer factory various abrasive slurry trasportation Water conservancy:Lake,river dredge, sediment,grit, High plastic clay Suction line to transportation Pump Spares MG Dredge Pump Spare Parts:  Our Own Factory

Our Own Factory

Contact Person Bruce Zhang

Contact Person Bruce ZhangSales Engineer

Shijiazhuang Gravel Slurry Pump Industry Co.,Ltd

Email: Sales5(at)gsslurrypump.com Skype: Sino.pumps Tel: +86-17603208259 Fax: +86-0311-83050889

Supplier Information

Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

[ Hebei China ]

- Business Type : Trade Company

- Product/Service : slurry pump , gravel pump , sand pump

- Tel : 15832159591

More > Other products from this company