Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

Basic Information

- Model No.: MH25B

- Packaging: International standard export Plywood Case per slurry pump

- Delivery Time: 3 Days

- Place of Origin: Hebei, China (Mainland)

- Brand: GS

Company Information Shijiazhuang Gravel Slurry Pump Industry Co.,ltd locates in Shijiazhuang, Hebei Province, China, it is an integrative production, research, design and sales company, specialized in manufacturing slurry pump products. The company acting as one of the national heavy machinery industry unit, now has been developed into a professional manufacturer of slurry pump, mud pump, slush pump, foam pump, sand-slurry pump.  RH product: 1. Horizontal, cantilevered, centrifugal, single stage slurry pump2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 3. Wear resistant and anti abrasion wet parts: High chrome alloy and rubber etc. They are completely interchangeable with each other 4. Easily replaceable liners: Liners are bolted to the casing. 5. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 6 Discharge direction can be positioned at intervals of 45 degrees 7. Simple maintenance throat bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple. 8. Sealing type: pcking seal,impeller sealing and mechanical seal. 9. Widely application: They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

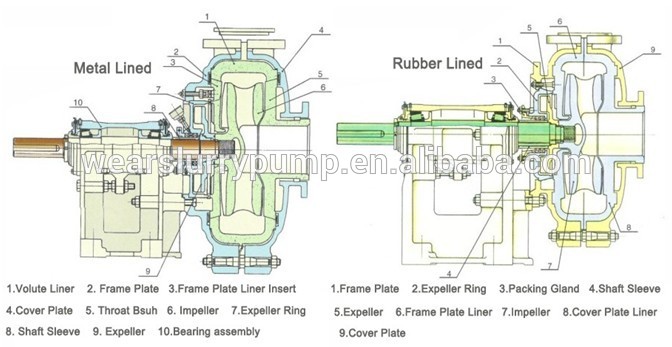

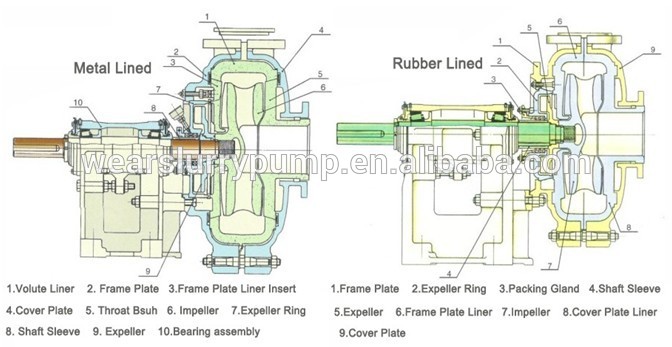

RH product: 1. Horizontal, cantilevered, centrifugal, single stage slurry pump2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 3. Wear resistant and anti abrasion wet parts: High chrome alloy and rubber etc. They are completely interchangeable with each other 4. Easily replaceable liners: Liners are bolted to the casing. 5. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 6 Discharge direction can be positioned at intervals of 45 degrees 7. Simple maintenance throat bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple. 8. Sealing type: pcking seal,impeller sealing and mechanical seal. 9. Widely application: They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

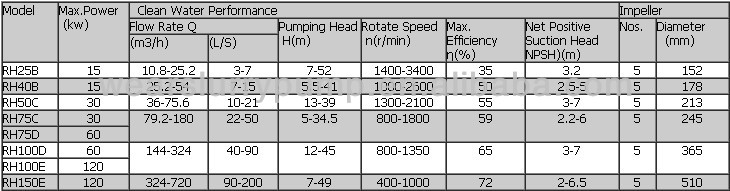

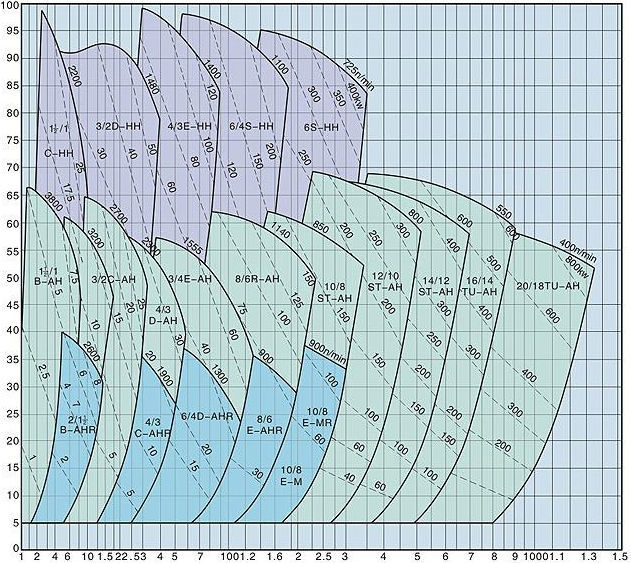

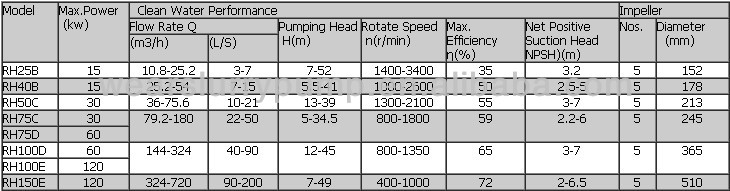

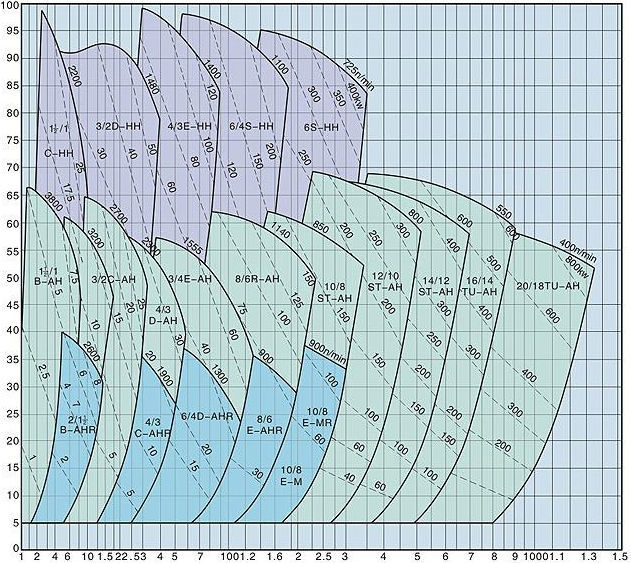

parameter selection RH Centrifugal Mining rubber Slurry Pump for Sand and Sludge Suction parameter selection table

parameter selection RH Centrifugal Mining rubber Slurry Pump for Sand and Sludge Suction parameter selection table

Meanings of the model: RH150X R----Anti-corrosive rubber material H---- Heavy type slurry pump 150----Pump Press out opening is 150mm

Meanings of the model: RH150X R----Anti-corrosive rubber material H---- Heavy type slurry pump 150----Pump Press out opening is 150mm

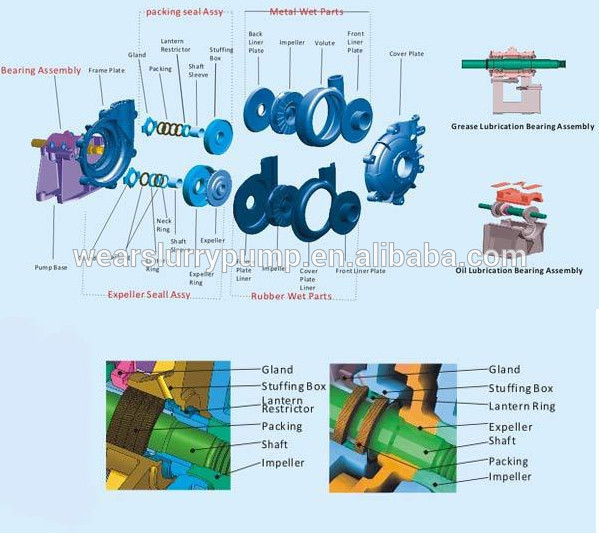

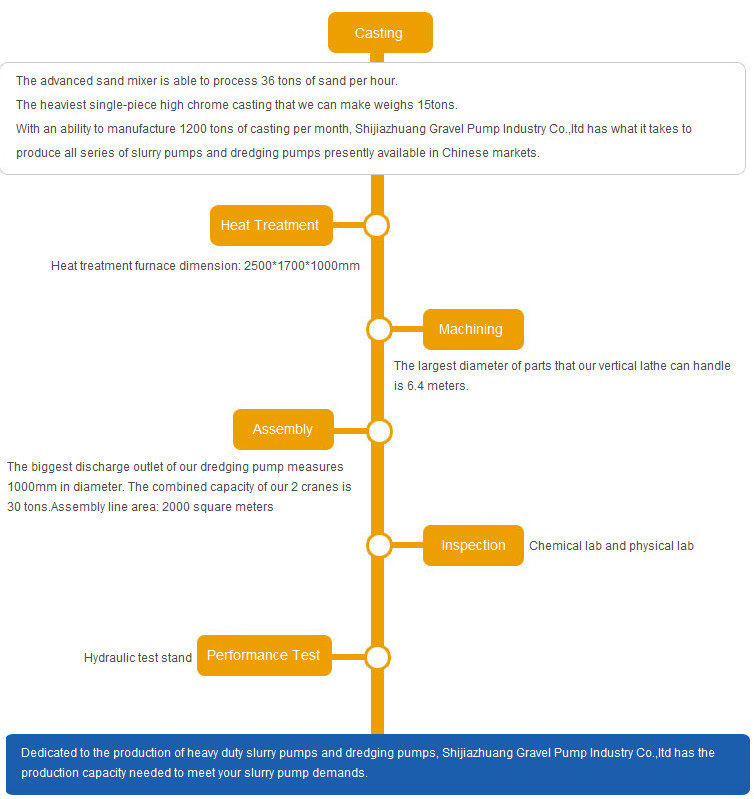

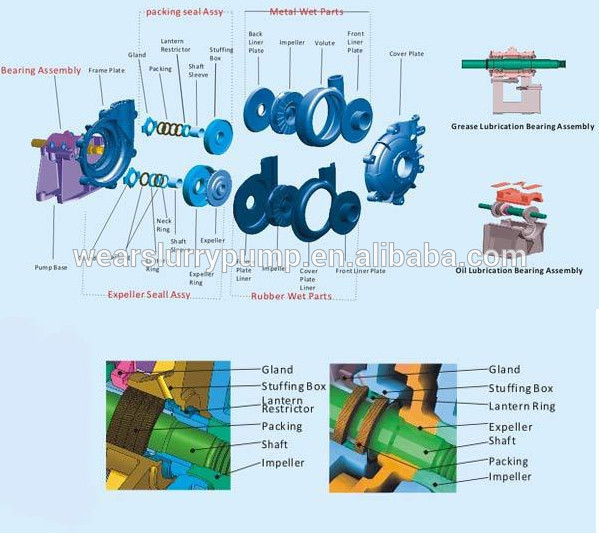

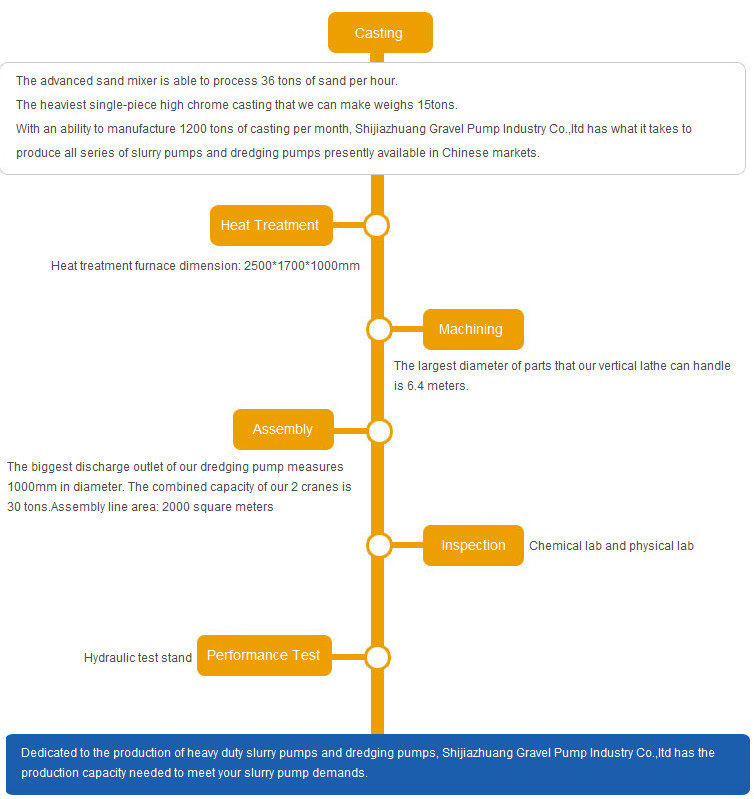

X----Bracket style component diagram. rubber slurry pump spare parts 1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity. 2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance. 3. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life. 4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety. 5. All of the rubber parts have superior erosion resisting performance which can be used for a long life. production process

production process

onsite application Pump high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and Liquid temperature up to 90℃.

onsite application Pump high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and Liquid temperature up to 90℃.

Packaging & Shipping As mostly we deliver by sea, so we package our pump and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard, its thickness is 10mm at least. Also we have professional workers to do this cases.We are very near to Tianjin seaport, so it is comfortable to deliver anytime, also the short delivery save the cost.

Packaging & Shipping As mostly we deliver by sea, so we package our pump and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard, its thickness is 10mm at least. Also we have professional workers to do this cases.We are very near to Tianjin seaport, so it is comfortable to deliver anytime, also the short delivery save the cost.

Our Service: OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. Quality control:

Our Service: OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. Quality control:

Our service: OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years. 2.What is your slurry pump manufacturing process? Casting------heat treatment----mechanical processing----assembly 3.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering Contact us Shijiazhuang Gravel Slurry Pump Industry Co.,ltd TEL: +86-311-85026467

Our service: OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years. 2.What is your slurry pump manufacturing process? Casting------heat treatment----mechanical processing----assembly 3.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering Contact us Shijiazhuang Gravel Slurry Pump Industry Co.,ltd TEL: +86-311-85026467

FAX: +86-311-83050889 Phone:13694098282 Skype:slurrypumptrade Email: sales3(at)gsslurrypump(dot)com Web: (dot)com

RH product: 1. Horizontal, cantilevered, centrifugal, single stage slurry pump2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 3. Wear resistant and anti abrasion wet parts: High chrome alloy and rubber etc. They are completely interchangeable with each other 4. Easily replaceable liners: Liners are bolted to the casing. 5. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 6 Discharge direction can be positioned at intervals of 45 degrees 7. Simple maintenance throat bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple. 8. Sealing type: pcking seal,impeller sealing and mechanical seal. 9. Widely application: They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

RH product: 1. Horizontal, cantilevered, centrifugal, single stage slurry pump2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 3. Wear resistant and anti abrasion wet parts: High chrome alloy and rubber etc. They are completely interchangeable with each other 4. Easily replaceable liners: Liners are bolted to the casing. 5. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 6 Discharge direction can be positioned at intervals of 45 degrees 7. Simple maintenance throat bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple. 8. Sealing type: pcking seal,impeller sealing and mechanical seal. 9. Widely application: They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

parameter selection RH Centrifugal Mining rubber Slurry Pump for Sand and Sludge Suction parameter selection table

parameter selection RH Centrifugal Mining rubber Slurry Pump for Sand and Sludge Suction parameter selection table

Meanings of the model: RH150X R----Anti-corrosive rubber material H---- Heavy type slurry pump 150----Pump Press out opening is 150mm

Meanings of the model: RH150X R----Anti-corrosive rubber material H---- Heavy type slurry pump 150----Pump Press out opening is 150mmX----Bracket style component diagram. rubber slurry pump spare parts 1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity. 2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance. 3. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life. 4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety. 5. All of the rubber parts have superior erosion resisting performance which can be used for a long life.

production process

production process

onsite application Pump high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and Liquid temperature up to 90℃.

onsite application Pump high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and Liquid temperature up to 90℃.

Packaging & Shipping As mostly we deliver by sea, so we package our pump and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard, its thickness is 10mm at least. Also we have professional workers to do this cases.We are very near to Tianjin seaport, so it is comfortable to deliver anytime, also the short delivery save the cost.

Packaging & Shipping As mostly we deliver by sea, so we package our pump and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard, its thickness is 10mm at least. Also we have professional workers to do this cases.We are very near to Tianjin seaport, so it is comfortable to deliver anytime, also the short delivery save the cost.

Our Service: OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. Quality control:

Our Service: OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. Quality control: Stages of manufacture | Quality cotrol activities |

| Raw material arrival | Sampling, material chemical analysis |

| Casting and composition | Material material chemical analysis of pump parts |

| Casting quality inspection | |

| Key component machining | Dimension precision inspection |

| Impeller balancing | |

| General assembly | Procedure operaion |

| Hydraulic static test | |

Performance test of pump unit | Capacity and head |

| Vibration and noise | |

| Bearing temperature | |

| Final inspection | Packaging of pump unit |

| Documents | |

| Spare parts and accessories |

Our service: OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years. 2.What is your slurry pump manufacturing process? Casting------heat treatment----mechanical processing----assembly 3.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering Contact us Shijiazhuang Gravel Slurry Pump Industry Co.,ltd TEL: +86-311-85026467

Our service: OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years. 2.What is your slurry pump manufacturing process? Casting------heat treatment----mechanical processing----assembly 3.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering Contact us Shijiazhuang Gravel Slurry Pump Industry Co.,ltd TEL: +86-311-85026467FAX: +86-311-83050889 Phone:13694098282 Skype:slurrypumptrade Email: sales3(at)gsslurrypump(dot)com Web: (dot)com

Supplier Information

Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

[ Hebei China ]

- Business Type : Trade Company

- Product/Service : slurry pump , gravel pump , sand pump

- Tel : 15832159591

More > Other products from this company