Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

Basic Information

- Model No.: MG

- Packaging: Standard wooden case

- Delivery Time: 3 Days

- Place of Origin: Hebei, China (Mainland)

- Brand: Shiao

Dewatering mud, sand,gravel slurry pump Product Description MG Gravel Pump Introduction: 1.Dredge and gravel slurry pump series are designed for transporting big particle slurry with horizontal and single-casing structure. 2.The Sand suction drege pump can continually deliver most abrasive slurry. They are suitable for delivering slurry from mining, dredging from river and explosive sludge from metal melting and other fields. 3.The dredge and gravel slurry pump are high head gravel ones. 4.Sand slurry pumps mainly used in: power plant, chemical process, coal, heavy minerals,paper and pulp, mill Lime grinding, bottom boiler fly,ash cyclone feed, slag granulation, suction hopper,dredging, barge loading, sand reclamation etc.  MG Gravel Pump Structural Drawing:

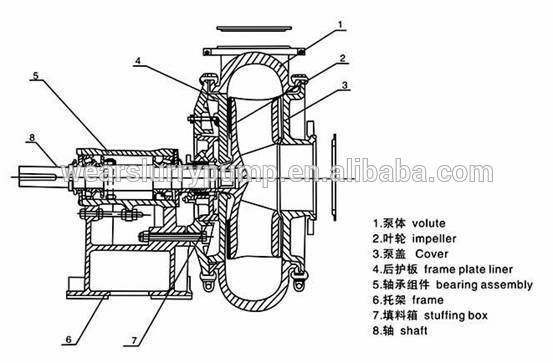

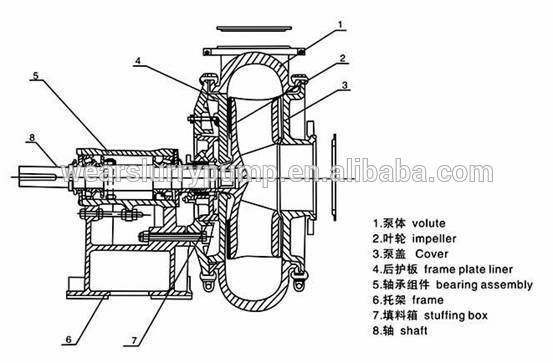

MG Gravel Pump Structural Drawing:

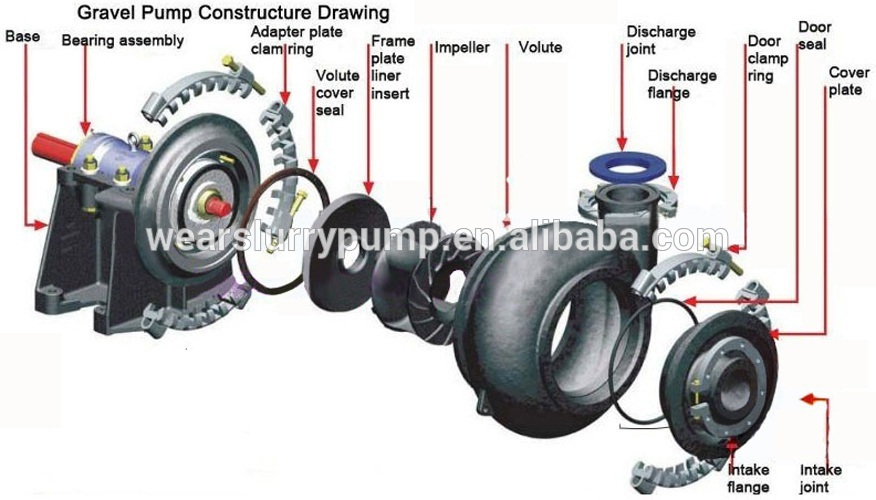

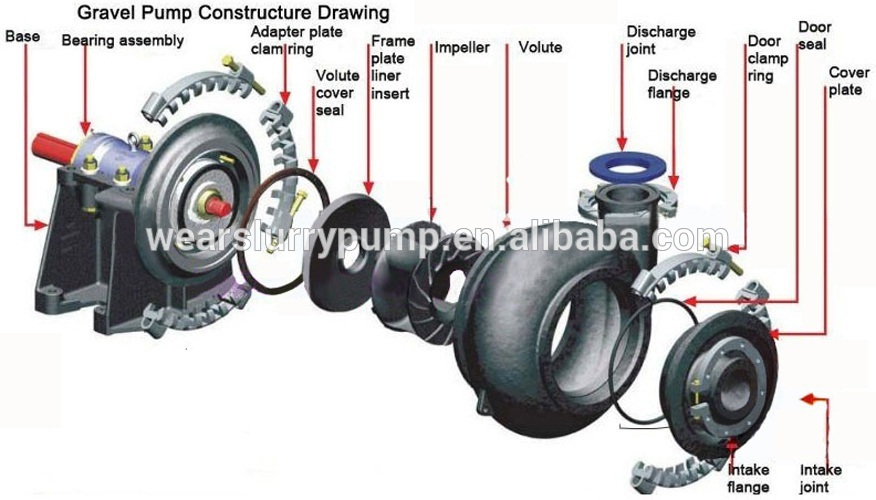

MG Gravel Pump Component Diagram: MG Gravel Pump Performance Chart:

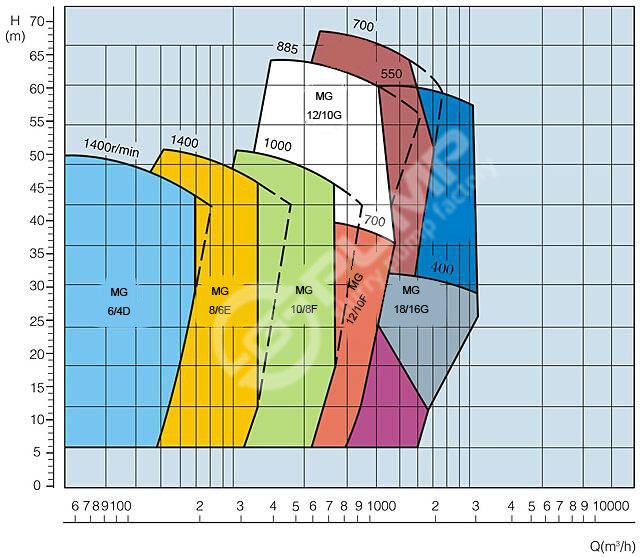

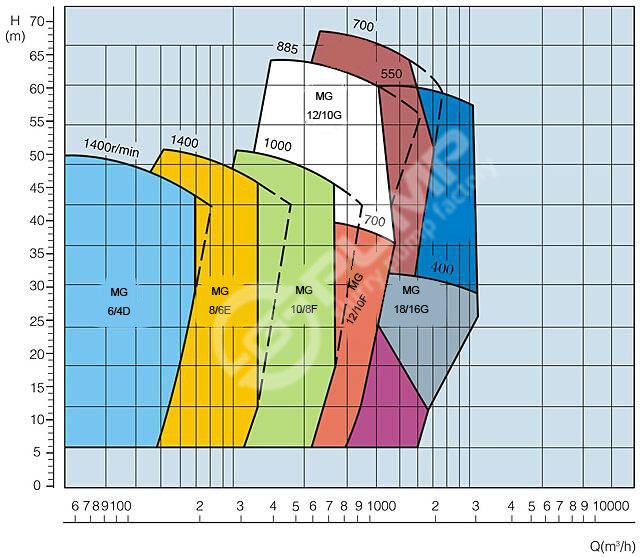

MG Gravel Pump Performance Chart:  MG Gravel Pump Performance Data Sheet:

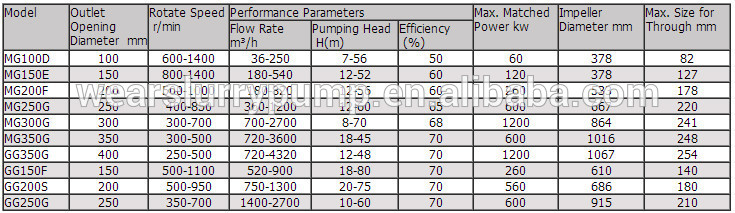

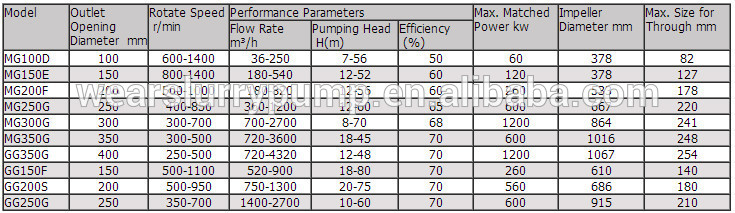

MG Gravel Pump Performance Data Sheet:

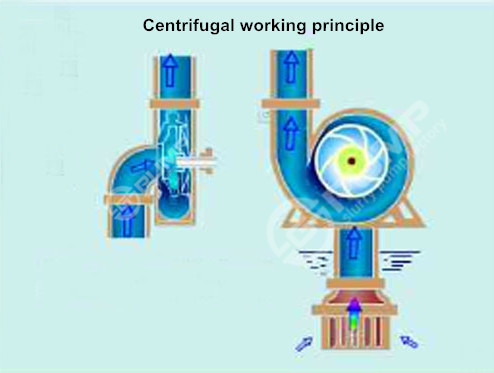

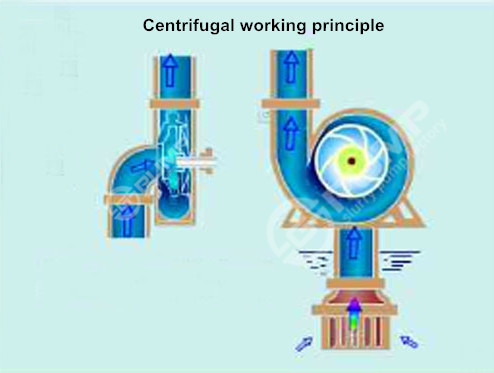

Features 1. Cantilevered, horizontal, centrifugal,single stage slurry pump

Features 1. Cantilevered, horizontal, centrifugal,single stage slurry pump

2. Widely application: the slurry pumps are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

3. Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

4. Easily replaceable liners: Liners are bolted to the casing.

5. Simple maintenance throat-bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple.

6. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

7. High efficiency and high head design are also available.

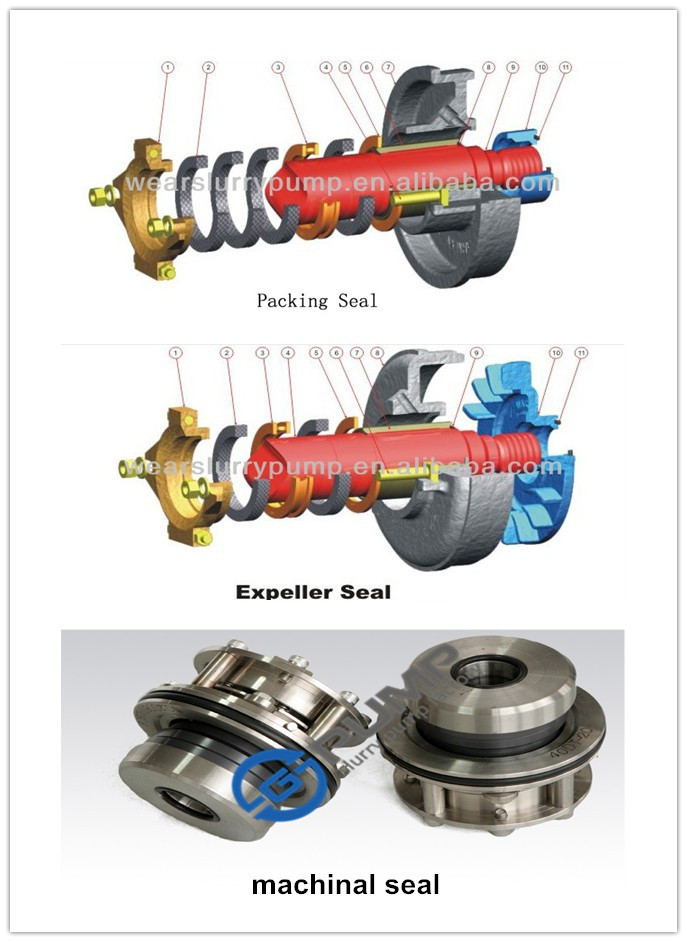

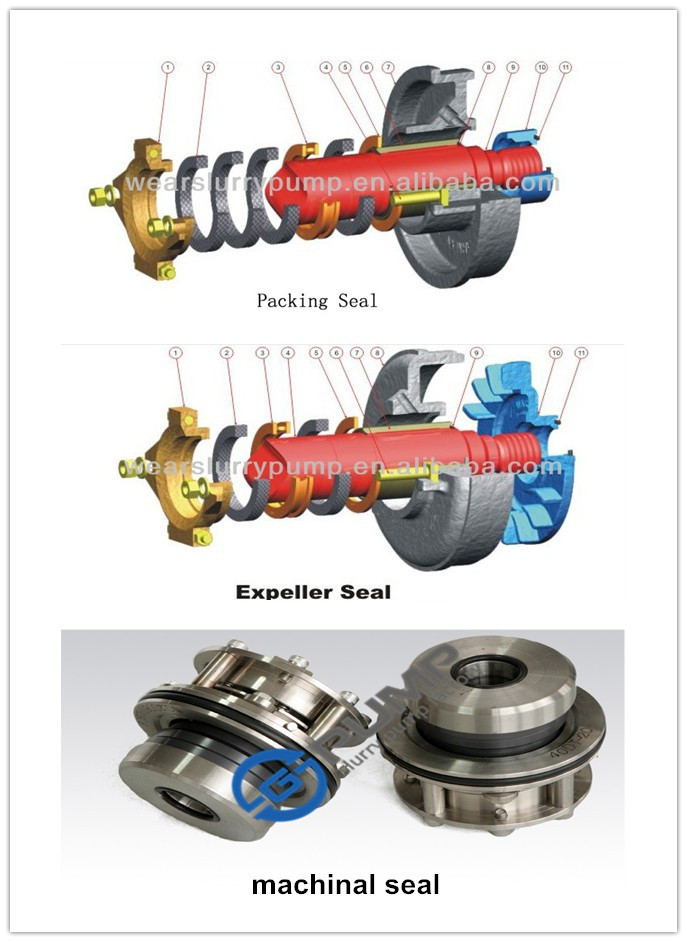

8. Sealing type: packing seal, impeller sealing and mechanical seal. Seal Type There are three standard shaft seal methods: Packing seal, Expeller seal, Mechanical seal. Packing Seal :

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal : MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications.

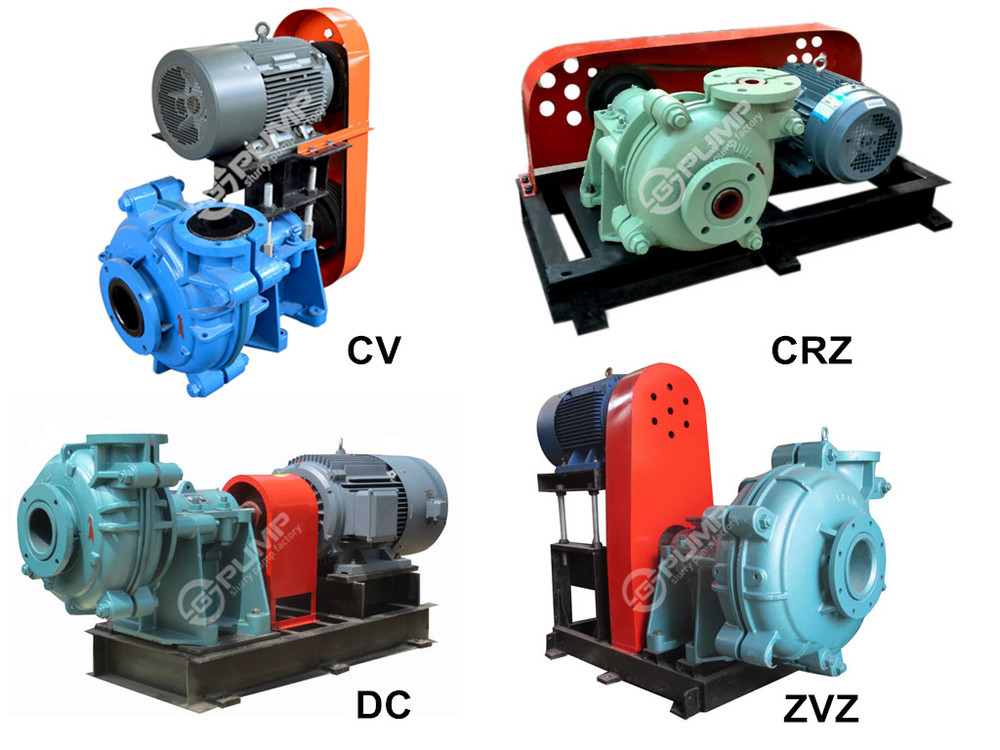

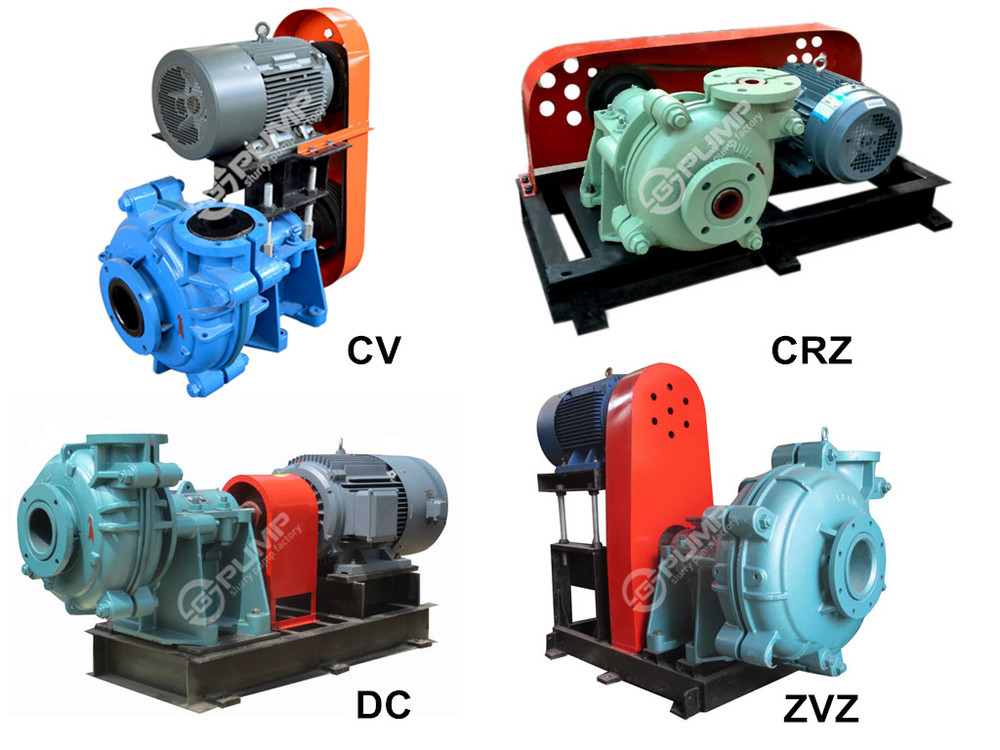

Drive type DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor.

DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor.

CV Type: The pump is driven by a belt connected to the crankshaft of the engine. This way of connection allows for saving space, easy installation, and fast adjustment of pumping speed. The motor is fixed to the motor support frame which is located on the bearing support above the slurry pump.

ZV Type: Another type of belt drive that allows easy adjustment of pumping speed. The motor is directly fixed to the bearing support. This way of installation is suitable for motors with larger horsepower than is possible with CV type of installation. Due to the installation of motor onto the bearing support, this method helps save installation space.

CR Type: This type of belt drive makes it easier to adjust pumping speed. The installation allows both the motor and slurry pump to be fixed to the ground. The motor is installed to the side of the pump. This installation method is suitable for large-power motors. Spare Parts We guarantee highest quality spare parts readily available to service for your process running. OEM or upgraded specification spare parts, coupled with full engineering design capability, will ensure reliability and optimimal performance time. Many of our slurry pump components, including impellers,frame & back liners,seals,bearing housings and bases. All slurry pump spare parts are 100% interchangeable with Warman & Weir pump brands. You will save your cost and time by working with our slurry pump. The material of spare parts are high chrome alloy or rubber and polyurethane.All are anti-wear and corrosion resistant.

High Chrome Alloy Spare Parts Natural Rubber Spare Parts

Natural Rubber Spare Parts  Polyurethane Spare Parts

Polyurethane Spare Parts

Application Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

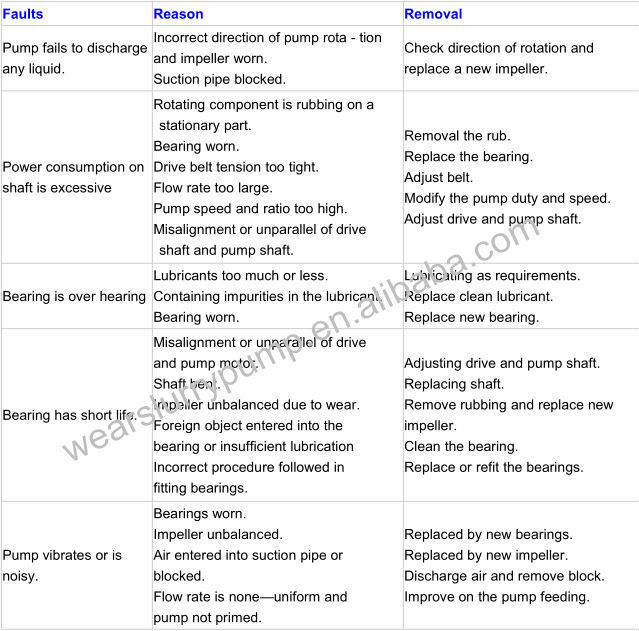

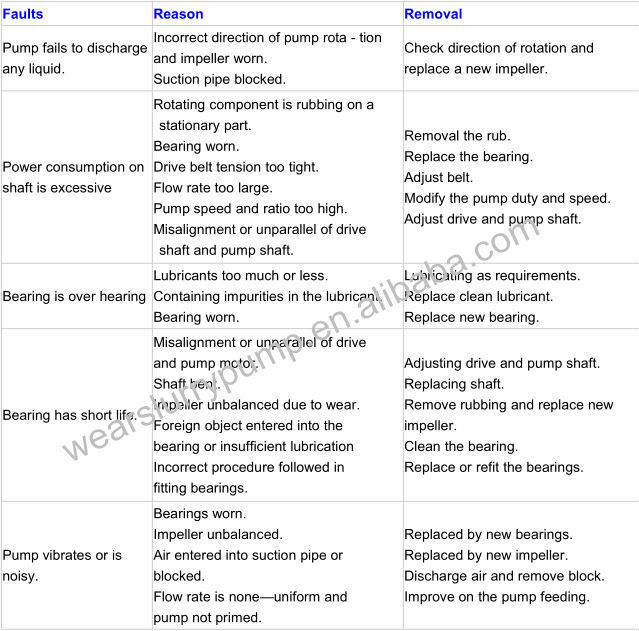

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Contact us Welcome to contact us!

MG Gravel Pump Structural Drawing:

MG Gravel Pump Structural Drawing:

MG Gravel Pump Component Diagram:

MG Gravel Pump Performance Chart:

MG Gravel Pump Performance Chart:  MG Gravel Pump Performance Data Sheet:

MG Gravel Pump Performance Data Sheet: Features 1. Cantilevered, horizontal, centrifugal,single stage slurry pump

Features 1. Cantilevered, horizontal, centrifugal,single stage slurry pump2. Widely application: the slurry pumps are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

3. Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

4. Easily replaceable liners: Liners are bolted to the casing.

5. Simple maintenance throat-bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple.

6. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

7. High efficiency and high head design are also available.

8. Sealing type: packing seal, impeller sealing and mechanical seal. Seal Type There are three standard shaft seal methods: Packing seal, Expeller seal, Mechanical seal. Packing Seal :

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal : MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications.

Drive type

DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor.

DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor. CV Type: The pump is driven by a belt connected to the crankshaft of the engine. This way of connection allows for saving space, easy installation, and fast adjustment of pumping speed. The motor is fixed to the motor support frame which is located on the bearing support above the slurry pump.

ZV Type: Another type of belt drive that allows easy adjustment of pumping speed. The motor is directly fixed to the bearing support. This way of installation is suitable for motors with larger horsepower than is possible with CV type of installation. Due to the installation of motor onto the bearing support, this method helps save installation space.

CR Type: This type of belt drive makes it easier to adjust pumping speed. The installation allows both the motor and slurry pump to be fixed to the ground. The motor is installed to the side of the pump. This installation method is suitable for large-power motors. Spare Parts We guarantee highest quality spare parts readily available to service for your process running. OEM or upgraded specification spare parts, coupled with full engineering design capability, will ensure reliability and optimimal performance time. Many of our slurry pump components, including impellers,frame & back liners,seals,bearing housings and bases. All slurry pump spare parts are 100% interchangeable with Warman & Weir pump brands. You will save your cost and time by working with our slurry pump. The material of spare parts are high chrome alloy or rubber and polyurethane.All are anti-wear and corrosion resistant.

High Chrome Alloy Spare Parts

Natural Rubber Spare Parts

Natural Rubber Spare Parts  Polyurethane Spare Parts

Polyurethane Spare Parts

Application Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Contact us Welcome to contact us!

Supplier Information

Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

[ Hebei China ]

- Business Type : Trade Company

- Product/Service : slurry pump , gravel pump , sand pump

- Tel : 15832159591

More > Other products from this company