Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

Basic Information

- Model No.: MG

- Packaging: Standard wooden case

- Delivery Time: 3 Days

- Place of Origin: Hebei, China (Mainland)

- Brand: Shiao

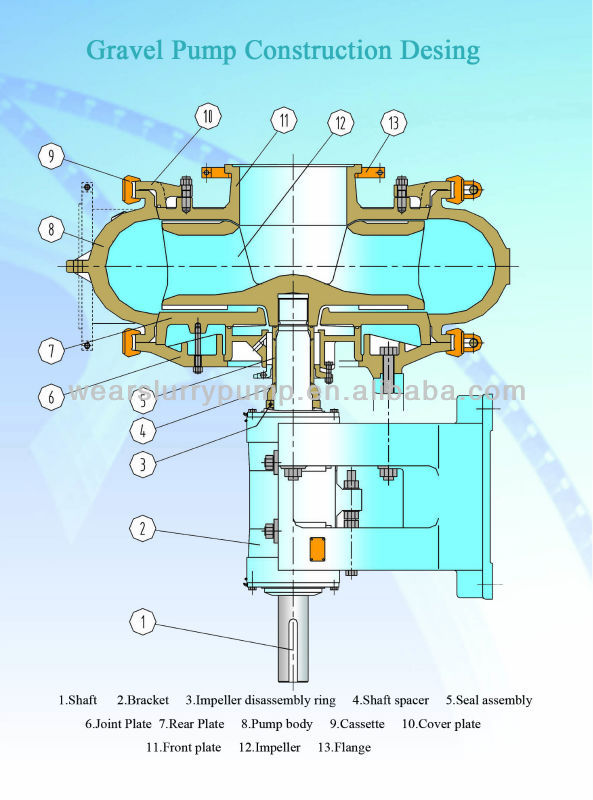

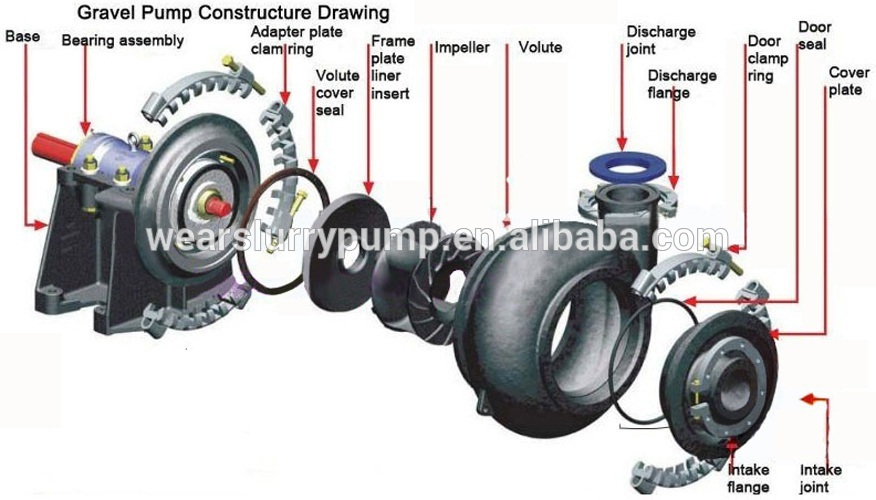

Electric Power fish farm filter mud slurry pump Product Description MG filter mud slurry pump machine introduction: 1. Mineral processing slurry pumping machine are designed for continuously handling the most difficult higher abrasive slurry which contain too big solids to be pumped by a common pump. 2.Dredging, suck gravel in the dredger, course of rivers. 3.Delivering slurries in mining, explosive sludge in metal smelting. 4.The discharge direction of pump can be oriented in any direction of 360°. 5.They are widely used for delivering slurry with strong abrasion and high concentration for metallurgy, mines, coal and power plant, etc  MG filter mud slurry pump machine structure drawing:

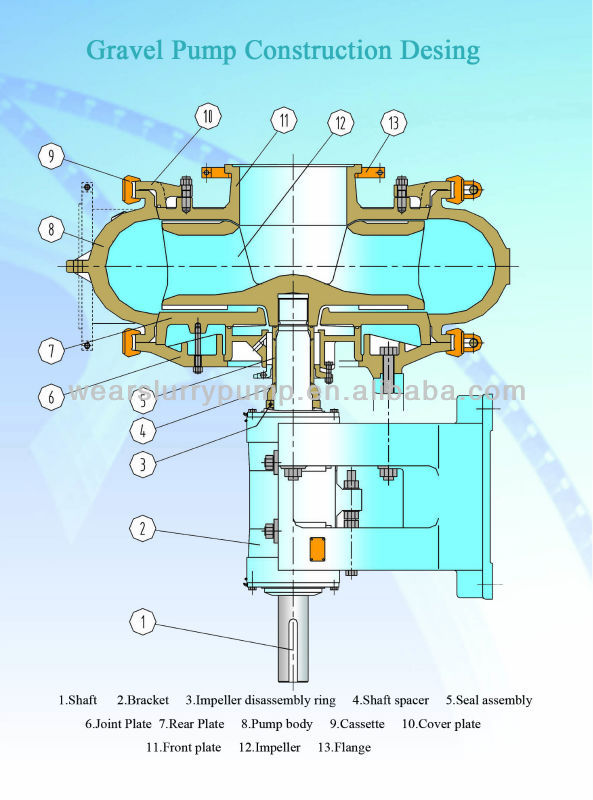

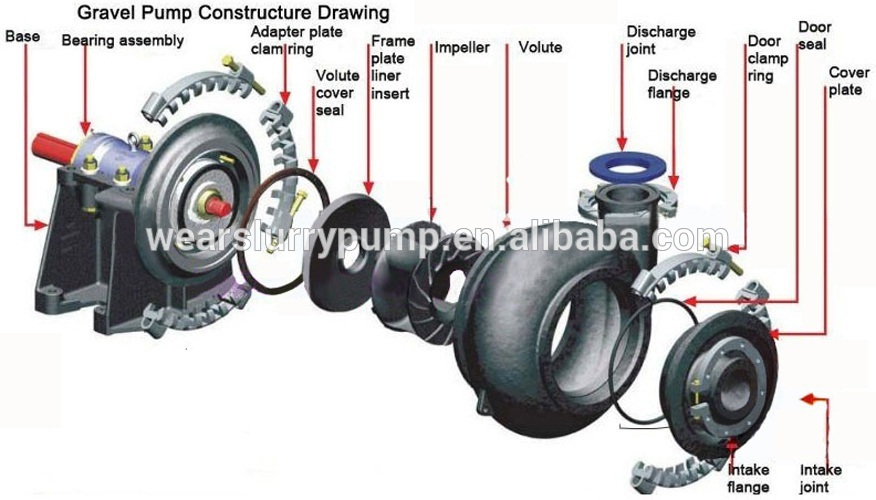

MG filter mud slurry pump machine structure drawing:

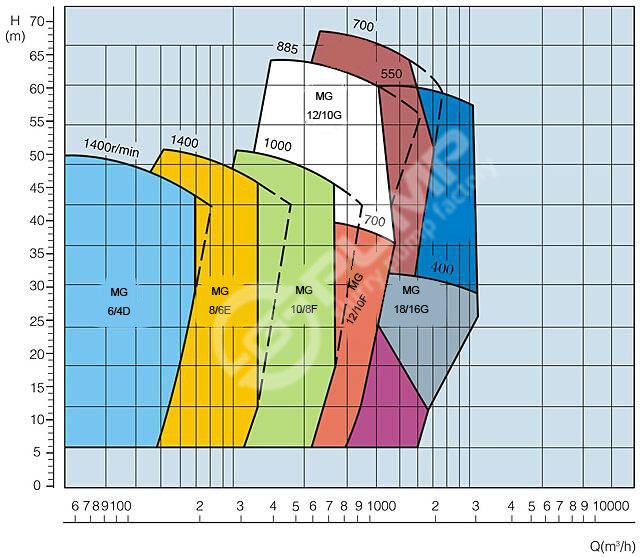

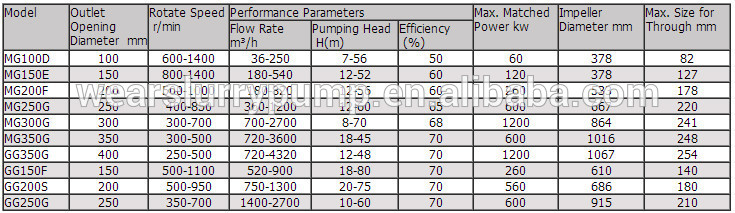

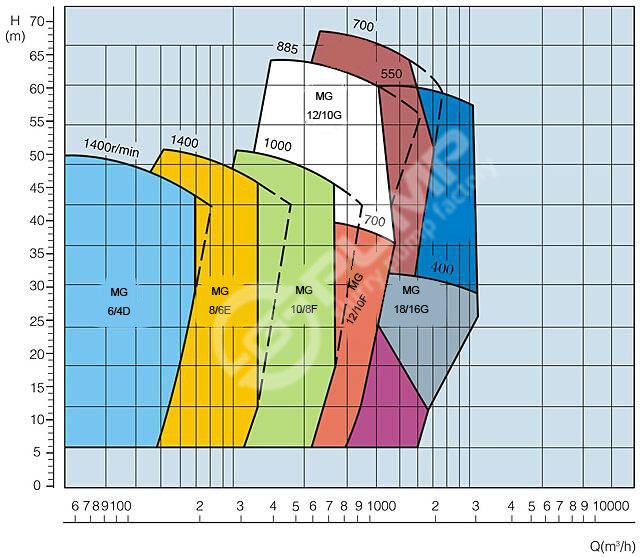

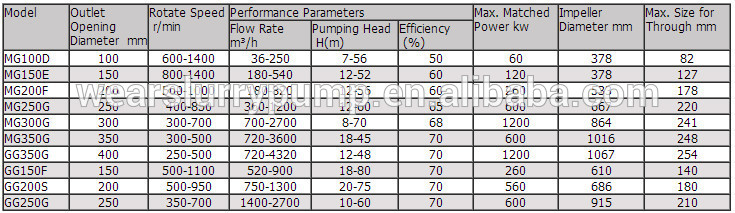

dredging mud processing slurry pumping machine 's casing and spare parts are all made of high chrome, anti-wear, anti-abrasive material,so the dredge pump can have very longer life . Mineral processing slurry pumping machine 's discharge direction can be oriented in any direction of 360°. MG filter mud slurry pump machine Performance parameter:

dredging mud processing slurry pumping machine 's casing and spare parts are all made of high chrome, anti-wear, anti-abrasive material,so the dredge pump can have very longer life . Mineral processing slurry pumping machine 's discharge direction can be oriented in any direction of 360°. MG filter mud slurry pump machine Performance parameter:

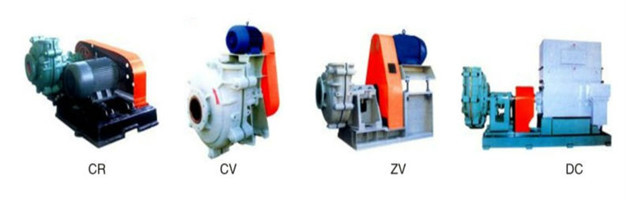

Drive type

Drive type  Features 1. Cantilevered, horizontal, centrifugal,single stage slurry pump

Features 1. Cantilevered, horizontal, centrifugal,single stage slurry pump

2. Widely application: the slurry pumps are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

3. Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

4. Easily replaceable liners: Liners are bolted to the casing.

5. Simple maintenance throat-bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple.

6. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

7. High efficiency and high head design are also available.

8. Sealing type: packing seal, impeller sealing and mechanical seal. Spare Parts We guarantee highest quality spare parts readily available to service for your process running. OEM or upgraded specification spare parts, coupled with full engineering design capability, will ensure reliability and optimimal performance time. Many of our slurry pump components, including impellers,frame & back liners,seals,bearing housings and bases. All slurry pump spare parts are 100% interchangeable with Warman & Weir pump brands. You will save your cost and time by working with our slurry pump. The material of spare parts are high chrome alloy or rubber and polyurethane.All are anti-wear and corrosion resistant.

High Chrome Alloy Spare Parts Natural Rubber Spare Parts

Natural Rubber Spare Parts  Polyurethane Spare Parts

Polyurethane Spare Parts

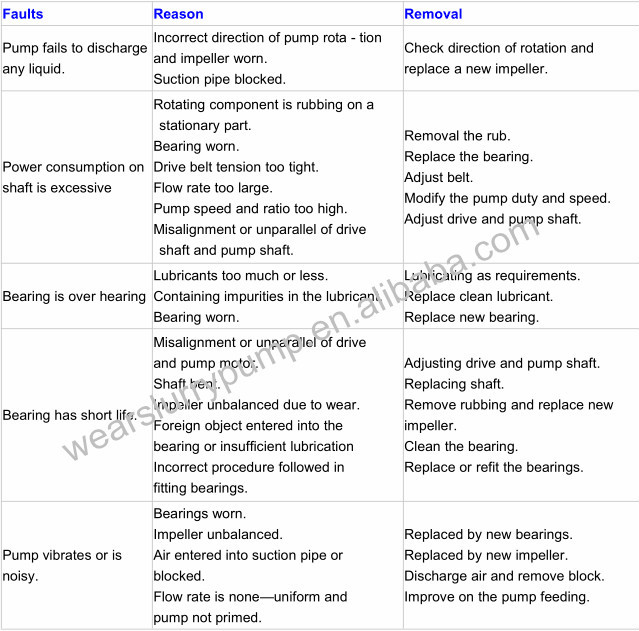

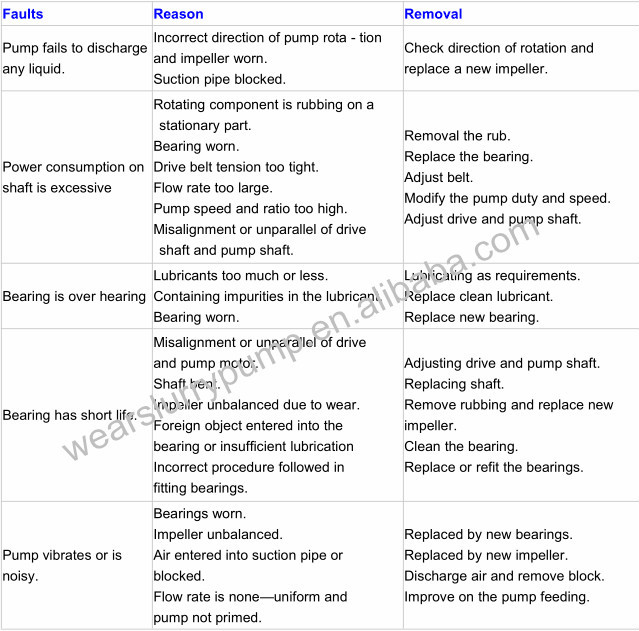

Application Horizontal centrifugal mining mud slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on. Problem&Removel Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Problem&Removel Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Processing&Workshop Test

Processing&Workshop Test  Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.

Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.  Contact us Welcome to contact us! Fax:+86-311-83050889 Tel: +86-311-85026467 Mobile: +86-18332008404 Skype: slurrypumpsupplier

Contact us Welcome to contact us! Fax:+86-311-83050889 Tel: +86-311-85026467 Mobile: +86-18332008404 Skype: slurrypumpsupplier

Email: sales2atgsslurrypump.com

MG filter mud slurry pump machine structure drawing:

MG filter mud slurry pump machine structure drawing:

dredging mud processing slurry pumping machine 's casing and spare parts are all made of high chrome, anti-wear, anti-abrasive material,so the dredge pump can have very longer life . Mineral processing slurry pumping machine 's discharge direction can be oriented in any direction of 360°. MG filter mud slurry pump machine Performance parameter:

dredging mud processing slurry pumping machine 's casing and spare parts are all made of high chrome, anti-wear, anti-abrasive material,so the dredge pump can have very longer life . Mineral processing slurry pumping machine 's discharge direction can be oriented in any direction of 360°. MG filter mud slurry pump machine Performance parameter:

Drive type

Drive type  Features 1. Cantilevered, horizontal, centrifugal,single stage slurry pump

Features 1. Cantilevered, horizontal, centrifugal,single stage slurry pump2. Widely application: the slurry pumps are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

3. Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

4. Easily replaceable liners: Liners are bolted to the casing.

5. Simple maintenance throat-bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple.

6. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

7. High efficiency and high head design are also available.

8. Sealing type: packing seal, impeller sealing and mechanical seal. Spare Parts We guarantee highest quality spare parts readily available to service for your process running. OEM or upgraded specification spare parts, coupled with full engineering design capability, will ensure reliability and optimimal performance time. Many of our slurry pump components, including impellers,frame & back liners,seals,bearing housings and bases. All slurry pump spare parts are 100% interchangeable with Warman & Weir pump brands. You will save your cost and time by working with our slurry pump. The material of spare parts are high chrome alloy or rubber and polyurethane.All are anti-wear and corrosion resistant.

High Chrome Alloy Spare Parts

Natural Rubber Spare Parts

Natural Rubber Spare Parts  Polyurethane Spare Parts

Polyurethane Spare Parts

Application Horizontal centrifugal mining mud slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

Problem&Removel Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Problem&Removel Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions: Processing&Workshop Test

Processing&Workshop Test  Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.

Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.  Contact us Welcome to contact us! Fax:+86-311-83050889 Tel: +86-311-85026467 Mobile: +86-18332008404 Skype: slurrypumpsupplier

Contact us Welcome to contact us! Fax:+86-311-83050889 Tel: +86-311-85026467 Mobile: +86-18332008404 Skype: slurrypumpsupplier Email: sales2atgsslurrypump.com

Supplier Information

Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

[ Hebei China ]

- Business Type : Trade Company

- Product/Service : slurry pump , gravel pump , sand pump

- Tel : 15832159591

More > Other products from this company