Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

Basic Information

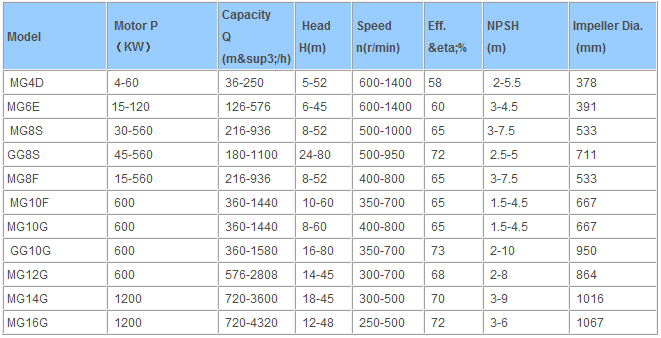

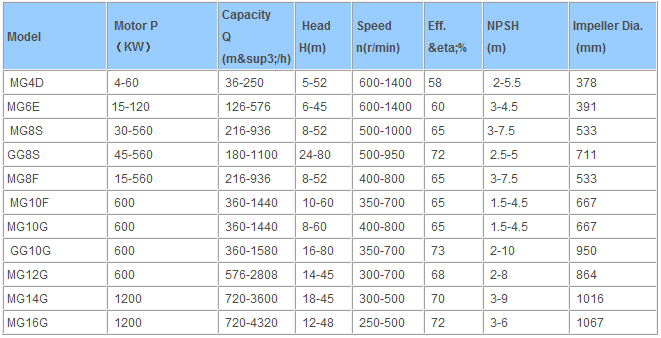

- Model No.: MG100D Gravel pump

- Packaging: Plywood case for normal pumps and machines, plate for heavy pumps and machines.

- Delivery Time: 5 Days

- Place of Origin: Hebei, China (Mainland)

- Brand: GS

Company Information Shijiazhuang Gravel Slurry Pump Industry Co.,ltd locates in Shijiazhuang, Hebei Province, China, it is an integrative production, research, design and sales company, specialized in manufacturing slurry pump products. The company acting as one of the national heavy machinery industry unit, now has been developed into a professional manufacturer of slurry pump, mud pump, slush pump, foam pump, sand-slurry pump. High chrome anti-abrasive Mine sand and gravel slurry pump

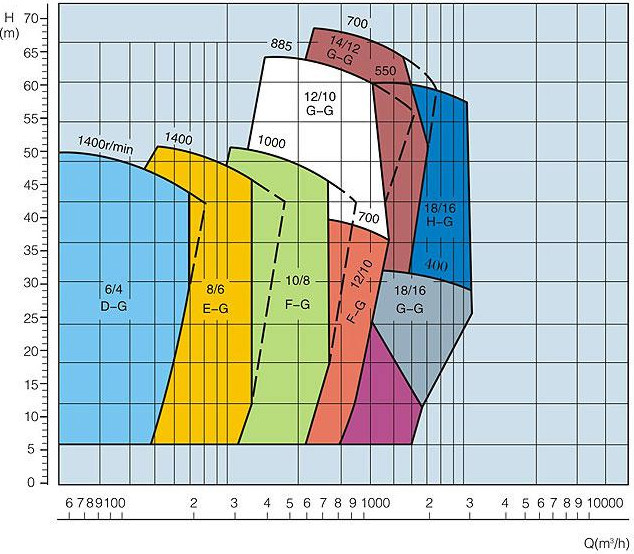

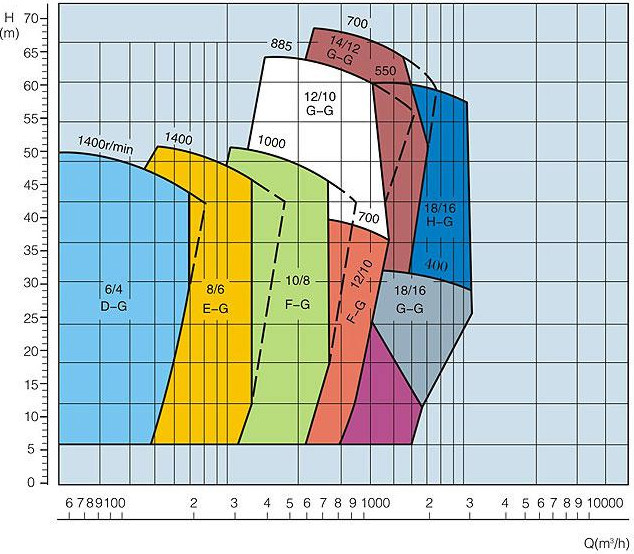

dredging pump introduction: 1.efficiency up to 92%(as measured in practice) resulting in lower fuel consumption at unchanged production 2.reduced and more even wear, resulting in longer lifetime of wear parts 3.highly versatile application due to steep flow head ratio curve 4.better performance as a result of the low net positive suction 5.improved resistance to cavitation 6.limited influence of wear on pump performance. dredging pump feature: Outlet: 4-16 inch

dredging pump introduction: 1.efficiency up to 92%(as measured in practice) resulting in lower fuel consumption at unchanged production 2.reduced and more even wear, resulting in longer lifetime of wear parts 3.highly versatile application due to steep flow head ratio curve 4.better performance as a result of the low net positive suction 5.improved resistance to cavitation 6.limited influence of wear on pump performance. dredging pump feature: Outlet: 4-16 inch

Capacity: to 4320 m³/h

Head: to 80 m

Type: Centrifugal, Horizontal, Single Casing

Wet Parts Materials:High chromium abrasion resistance alloys

Replacement: Interchangeable with other pumps dimensional dredging pump modal explanation:MG6E M:high chrome alloy G:gravel pump 6:Discharge diameter (inch) E:Frame type with maximum power

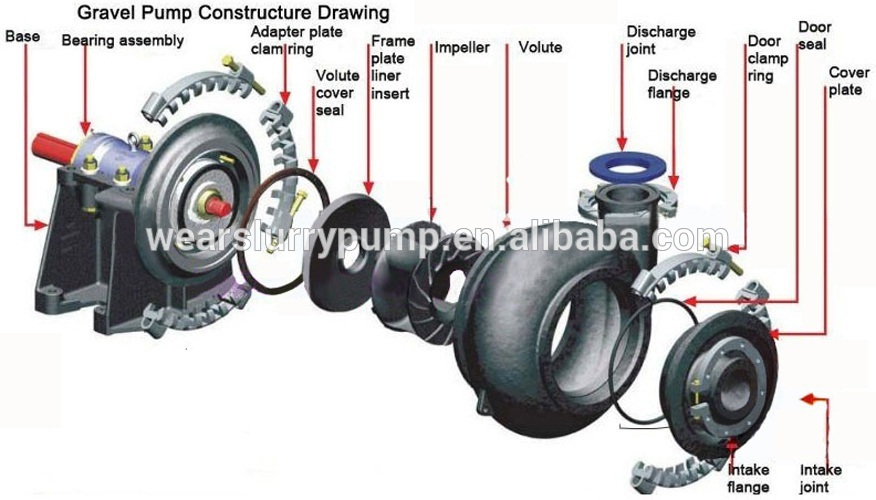

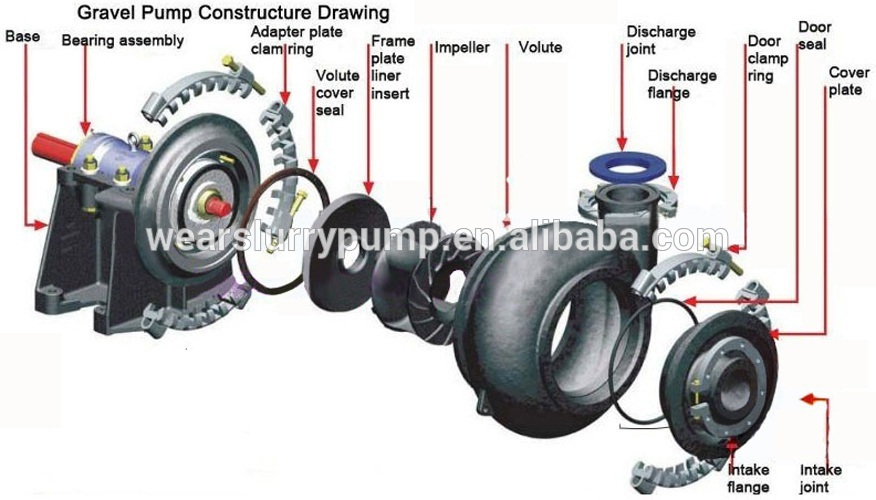

dredging pump structure:

dredging pump structure:  dredging component diagram:

dredging component diagram:  shaft seal: Packing Seal :

shaft seal: Packing Seal :

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal :

MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications. We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction. Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions. Drive type: DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor.

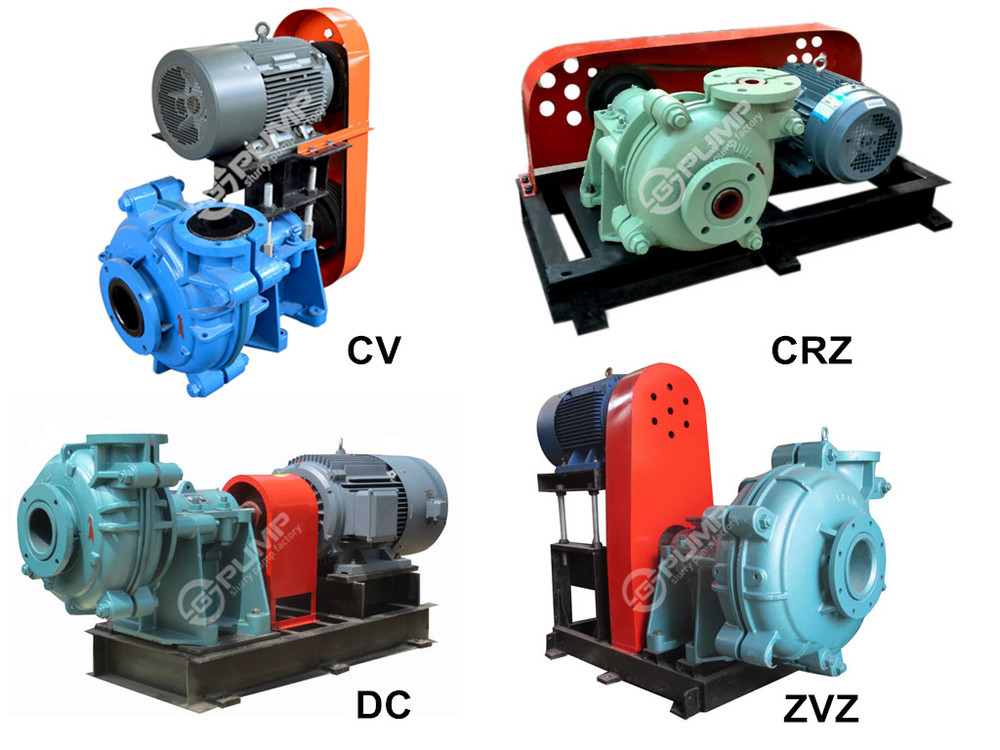

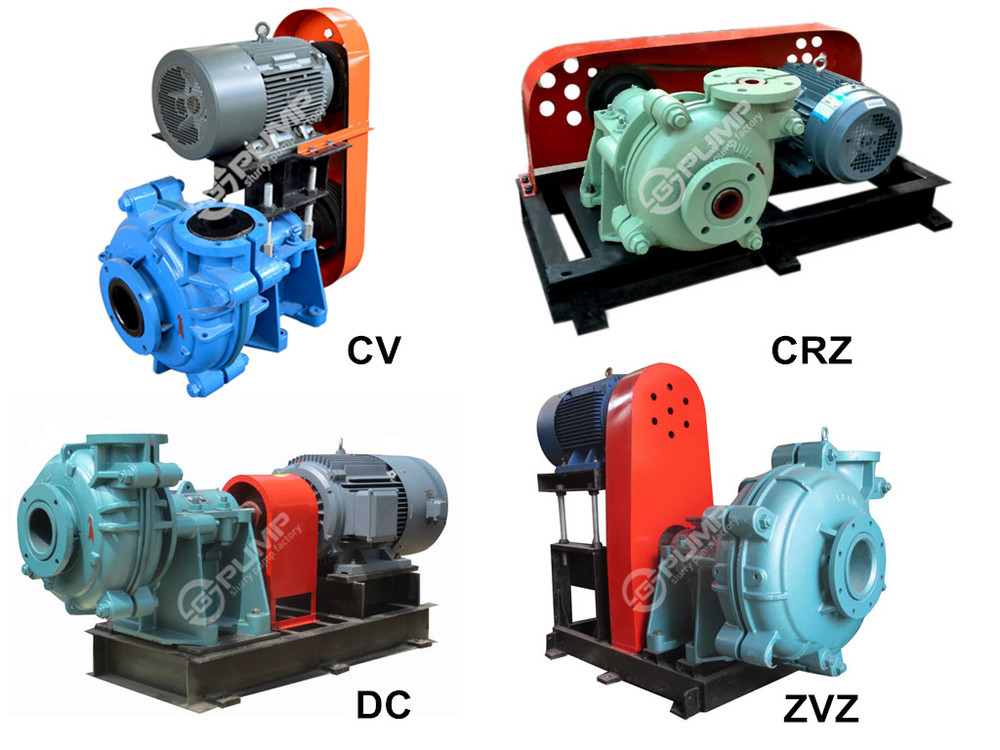

Drive type: DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor.

CV Type: The pump is driven by a belt connected to the crankshaft of the engine. This way of connection allows for saving space, easy installation, and fast adjustment of pumping speed. The motor is fixed to the motor support frame which is located on the bearing support above the slurry pump.

ZV Type: Another type of belt drive that allows easy adjustment of pumping speed. The motor is directly fixed to the bearing support. This way of installation is suitable for motors with larger horsepower than is possible with CV type of installation. Due to the installation of motor onto the bearing support, this method helps save installation space.

CR Type: This type of belt drive makes it easier to adjust pumping speed. The installation allows both the motor and slurry pump to be fixed to the ground. The motor is installed to the side of the pump. This installation method is suitable for large-power motors. related product: We can produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting. Such as following type: 1. MH(RH)series Metal/ Rubber Lined Horizontal Slurry Pump 2. MMseries Medium Duty Slurry Pump 3. ML(LR) series Low Abrasive Slurry Pump 4. GH series High Head Slurry Pump 5.MG series Sand and Gravel Pump 6. ZJ/ ZJL series Filter Press Feed Pump 7. MV(R) series Vertical Slurry Pump 8.MF(R) series Vertical Froth Pump 9. ZGB series Heavy Slurry Pump 10. OEM series Slurry Pump 11. All Pump Spare Parts

related product: We can produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting. Such as following type: 1. MH(RH)series Metal/ Rubber Lined Horizontal Slurry Pump 2. MMseries Medium Duty Slurry Pump 3. ML(LR) series Low Abrasive Slurry Pump 4. GH series High Head Slurry Pump 5.MG series Sand and Gravel Pump 6. ZJ/ ZJL series Filter Press Feed Pump 7. MV(R) series Vertical Slurry Pump 8.MF(R) series Vertical Froth Pump 9. ZGB series Heavy Slurry Pump 10. OEM series Slurry Pump 11. All Pump Spare Parts  shijiazhuang gravel slurry pump company workshop

shijiazhuang gravel slurry pump company workshop  dredging pump processing:

dredging pump processing:  Pump Prossible faults and removal:

Pump Prossible faults and removal:

Onsite application Mine:Black, non-ferrous ore slurry material pump and all kinds of concentrate and tailings conveying Metallurgy:Transport various slurry for aluminium or steel manufacture Coal: Coal mining, washing and various coarse and fine coal slurry transportation Electricity:Remove power plant ash,wash ash,various ash dregs or ash slurry transportation Construction materials:Various mud sand slurry(such as Cement slurry) transportation Chemical: Phosphatic fertilizer or potassic fertilizer factory various abrasive slurry trasportation Water conservancy:Lake,river dredge, sediment,grit, High plastic clay Suction line to transportation  Quality control:

Quality control:

Packing & Shipping

Packing & Shipping  our service: 1. We can produce the pump and spare parts following clients drawing or sample. 2. We help customers select the type, size and operating speed of pumps that will perform at the lowest cost of ownership. 3. Interchangeable metal design allow best material choice for any application. 4. Perfect After-sales service and large stock for standard spare parts. We provide lifetime after sale service to solve any question during client’s uses. 5. We offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Our products got the CE and ISO9001 certificate. 6. We always pay more attention to the quality of the slurry pump. Standard quality control system and team are responsible to insure the product quality in every process with different instruments. 7. One year guarantee for whole machine except of the wet end parts.

our service: 1. We can produce the pump and spare parts following clients drawing or sample. 2. We help customers select the type, size and operating speed of pumps that will perform at the lowest cost of ownership. 3. Interchangeable metal design allow best material choice for any application. 4. Perfect After-sales service and large stock for standard spare parts. We provide lifetime after sale service to solve any question during client’s uses. 5. We offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Our products got the CE and ISO9001 certificate. 6. We always pay more attention to the quality of the slurry pump. Standard quality control system and team are responsible to insure the product quality in every process with different instruments. 7. One year guarantee for whole machine except of the wet end parts.  Why choose us: 1. About 30 years Design, produce and service experience. 2.High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate 3.Good service. We have one of group high quality technicians who can help you solve any question during the process 4.Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon 5.Competitive price: As we are the direct factory. we have our casting workshop, machine workshop and Assembly Shop. 6.Rich export Experience. we had export USA, Germany,cannada , Austrilia and so on developed country and South africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high Reputation at home and abroad.

Why choose us: 1. About 30 years Design, produce and service experience. 2.High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate 3.Good service. We have one of group high quality technicians who can help you solve any question during the process 4.Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon 5.Competitive price: As we are the direct factory. we have our casting workshop, machine workshop and Assembly Shop. 6.Rich export Experience. we had export USA, Germany,cannada , Austrilia and so on developed country and South africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high Reputation at home and abroad.

dredging pump introduction: 1.efficiency up to 92%(as measured in practice) resulting in lower fuel consumption at unchanged production 2.reduced and more even wear, resulting in longer lifetime of wear parts 3.highly versatile application due to steep flow head ratio curve 4.better performance as a result of the low net positive suction 5.improved resistance to cavitation 6.limited influence of wear on pump performance. dredging pump feature: Outlet: 4-16 inch

dredging pump introduction: 1.efficiency up to 92%(as measured in practice) resulting in lower fuel consumption at unchanged production 2.reduced and more even wear, resulting in longer lifetime of wear parts 3.highly versatile application due to steep flow head ratio curve 4.better performance as a result of the low net positive suction 5.improved resistance to cavitation 6.limited influence of wear on pump performance. dredging pump feature: Outlet: 4-16 inchCapacity: to 4320 m³/h

Head: to 80 m

Type: Centrifugal, Horizontal, Single Casing

Wet Parts Materials:High chromium abrasion resistance alloys

Replacement: Interchangeable with other pumps dimensional dredging pump modal explanation:MG6E M:high chrome alloy G:gravel pump 6:Discharge diameter (inch) E:Frame type with maximum power

dredging pump structure:

dredging pump structure:  dredging component diagram:

dredging component diagram:  shaft seal: Packing Seal :

shaft seal: Packing Seal :As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal :

MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications. We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction. Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions.

Drive type: DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor.

Drive type: DC Type: The output shaft of a motor is directly connected to the input shaft of a pump via a pump coupler. This type of connection is suitable for applications where the speed of the slurry pump is the same as that of the motor. CV Type: The pump is driven by a belt connected to the crankshaft of the engine. This way of connection allows for saving space, easy installation, and fast adjustment of pumping speed. The motor is fixed to the motor support frame which is located on the bearing support above the slurry pump.

ZV Type: Another type of belt drive that allows easy adjustment of pumping speed. The motor is directly fixed to the bearing support. This way of installation is suitable for motors with larger horsepower than is possible with CV type of installation. Due to the installation of motor onto the bearing support, this method helps save installation space.

CR Type: This type of belt drive makes it easier to adjust pumping speed. The installation allows both the motor and slurry pump to be fixed to the ground. The motor is installed to the side of the pump. This installation method is suitable for large-power motors.

related product: We can produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting. Such as following type: 1. MH(RH)series Metal/ Rubber Lined Horizontal Slurry Pump 2. MMseries Medium Duty Slurry Pump 3. ML(LR) series Low Abrasive Slurry Pump 4. GH series High Head Slurry Pump 5.MG series Sand and Gravel Pump 6. ZJ/ ZJL series Filter Press Feed Pump 7. MV(R) series Vertical Slurry Pump 8.MF(R) series Vertical Froth Pump 9. ZGB series Heavy Slurry Pump 10. OEM series Slurry Pump 11. All Pump Spare Parts

related product: We can produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting. Such as following type: 1. MH(RH)series Metal/ Rubber Lined Horizontal Slurry Pump 2. MMseries Medium Duty Slurry Pump 3. ML(LR) series Low Abrasive Slurry Pump 4. GH series High Head Slurry Pump 5.MG series Sand and Gravel Pump 6. ZJ/ ZJL series Filter Press Feed Pump 7. MV(R) series Vertical Slurry Pump 8.MF(R) series Vertical Froth Pump 9. ZGB series Heavy Slurry Pump 10. OEM series Slurry Pump 11. All Pump Spare Parts  shijiazhuang gravel slurry pump company workshop

shijiazhuang gravel slurry pump company workshop  dredging pump processing:

dredging pump processing:  Pump Prossible faults and removal:

Pump Prossible faults and removal: | Faults | Reason | Removal |

| Pump fails to discharge any liquid. | Incorrect direction of pump rota- tion and impeller worn. Suction pipe blocked | Check direction of rotation and replace a new impeller |

| Power consumption on sh- aft is excessive | Rotating component is rubbing on a stationary part. Bearing worn. Drive belt tension too tight Flow rate too large Pump speed and ratio too high. Misalignment or unparallel of ddrive shaft and pump shaft. | Removal the rub Replace the bearing Adjust belt Modify the pump duty and speed. Adjust drive and pump shaft |

| Bearing is over hearing | Lubricants too much or less. Containing impurities in the lubricant Bearing worn. | Lubricating as requirements. Replace clean lubricant. Replace new bearing. |

| Bearing has short life. | Misalignment or unparallel of drive and pump motor. Shaft bent. Impeller unbalanced due to wear Foreign object entered into the bearing or insufficient lubrication Incorrect procedure followed in fitting bearings. | Adjusting drive and pump shaft. Replacing shaft. Remove rubbing and replace new impeller Clean the bearing. Replace or refit the bearings. |

| Pump vibrates or is noisy. | Bearings worn. Impeller unbalanced. Air entered into suction pipe or blocked. Flow rate is none—uniform and pump not primed. | Replaced by new bearings. Replaced by new impeller. Discharge air and remove block. Improve on the pump feeding. |

Quality control:

Quality control: Stages of manufacture | Quality cotrol activities |

| Raw material arrival | Sampling, material chemical analysis |

| Casting and composition | Material material chemical analysis of pump parts |

| Casting quality inspection | |

| Key component machining | Dimension precision inspection |

| Impeller balancing | |

| General assembly | Procedure operaion |

| Hydraulic static test | |

Performance test of pump unit | Capacity and head |

| Vibration and noise | |

| Bearing temperature | |

| Final inspection | Packaging of pump unit |

| Documents | |

| Spare parts and accessories |

Packing & Shipping

Packing & Shipping  our service: 1. We can produce the pump and spare parts following clients drawing or sample. 2. We help customers select the type, size and operating speed of pumps that will perform at the lowest cost of ownership. 3. Interchangeable metal design allow best material choice for any application. 4. Perfect After-sales service and large stock for standard spare parts. We provide lifetime after sale service to solve any question during client’s uses. 5. We offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Our products got the CE and ISO9001 certificate. 6. We always pay more attention to the quality of the slurry pump. Standard quality control system and team are responsible to insure the product quality in every process with different instruments. 7. One year guarantee for whole machine except of the wet end parts.

our service: 1. We can produce the pump and spare parts following clients drawing or sample. 2. We help customers select the type, size and operating speed of pumps that will perform at the lowest cost of ownership. 3. Interchangeable metal design allow best material choice for any application. 4. Perfect After-sales service and large stock for standard spare parts. We provide lifetime after sale service to solve any question during client’s uses. 5. We offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Our products got the CE and ISO9001 certificate. 6. We always pay more attention to the quality of the slurry pump. Standard quality control system and team are responsible to insure the product quality in every process with different instruments. 7. One year guarantee for whole machine except of the wet end parts.  Why choose us: 1. About 30 years Design, produce and service experience. 2.High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate 3.Good service. We have one of group high quality technicians who can help you solve any question during the process 4.Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon 5.Competitive price: As we are the direct factory. we have our casting workshop, machine workshop and Assembly Shop. 6.Rich export Experience. we had export USA, Germany,cannada , Austrilia and so on developed country and South africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high Reputation at home and abroad.

Why choose us: 1. About 30 years Design, produce and service experience. 2.High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate 3.Good service. We have one of group high quality technicians who can help you solve any question during the process 4.Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon 5.Competitive price: As we are the direct factory. we have our casting workshop, machine workshop and Assembly Shop. 6.Rich export Experience. we had export USA, Germany,cannada , Austrilia and so on developed country and South africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high Reputation at home and abroad.

Supplier Information

Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

[ Hebei China ]

- Business Type : Trade Company

- Product/Service : slurry pump , gravel pump , sand pump

- Tel : 15832159591

More > Other products from this company