Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

Basic Information

- Model No.: MG

- Packaging: Wooden case, or as the buyer\'s request

- Place of Origin: Hebei, China (Mainland)

- Brand: ShiAo

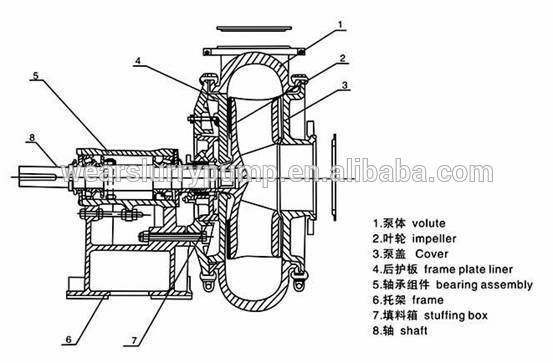

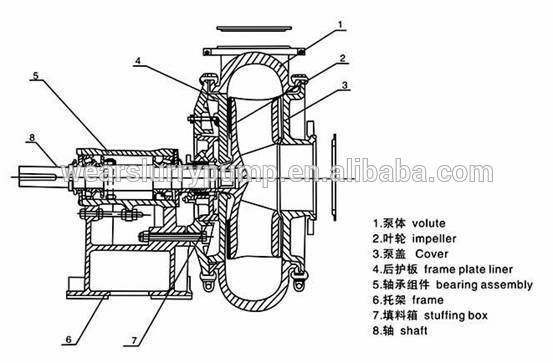

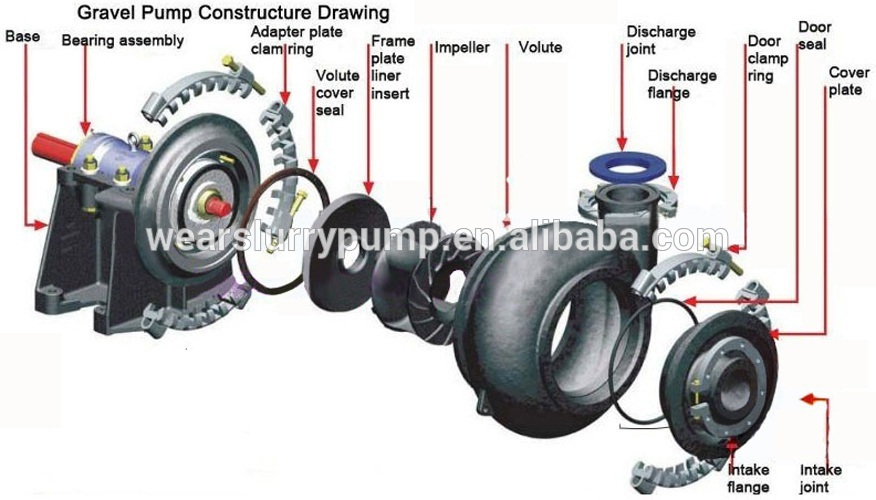

Product Description MG Gravel Pump Structural Drawing:

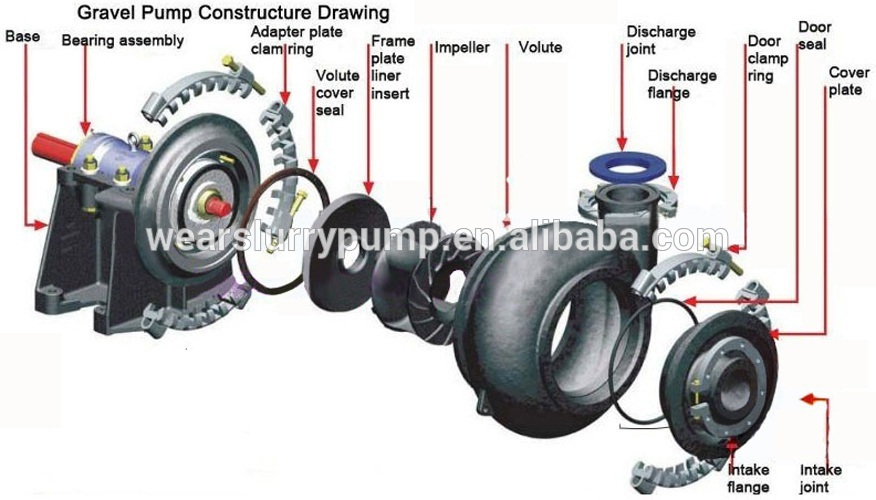

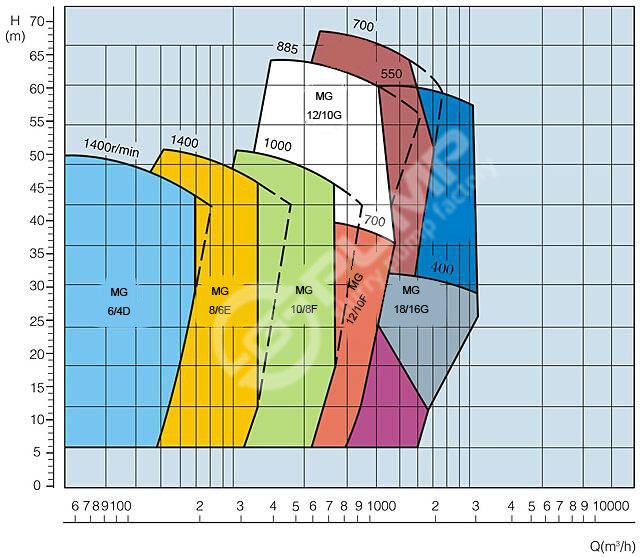

MG Gravel Pump Component Diagram: MG Gravel Pump Performance Chart:

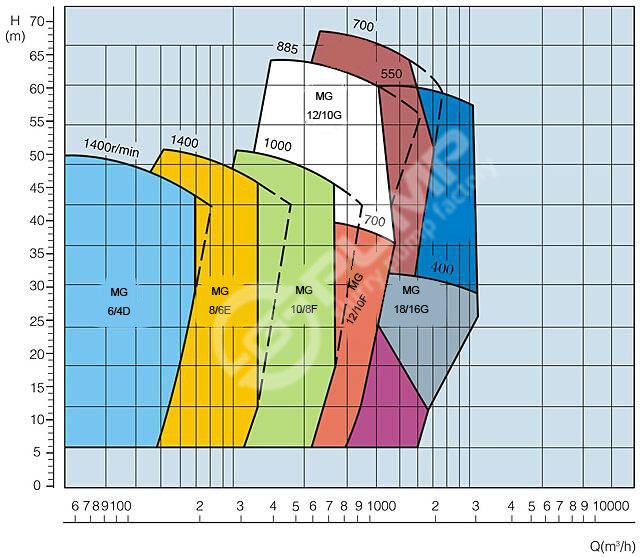

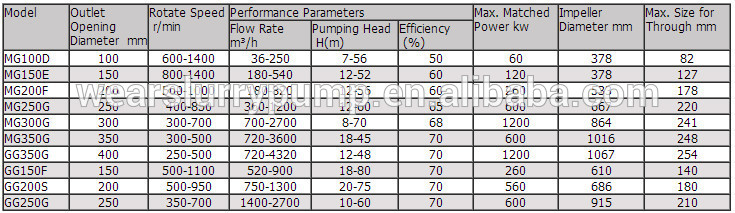

MG Gravel Pump Performance Chart:  MG Gravel Pump Performance Data Sheet:

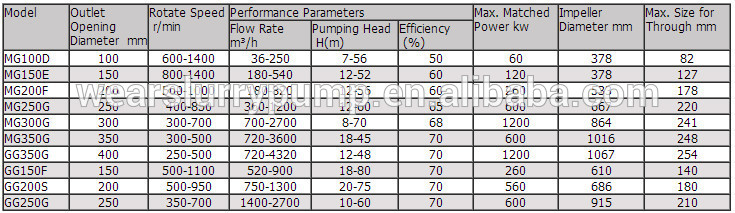

MG Gravel Pump Performance Data Sheet:

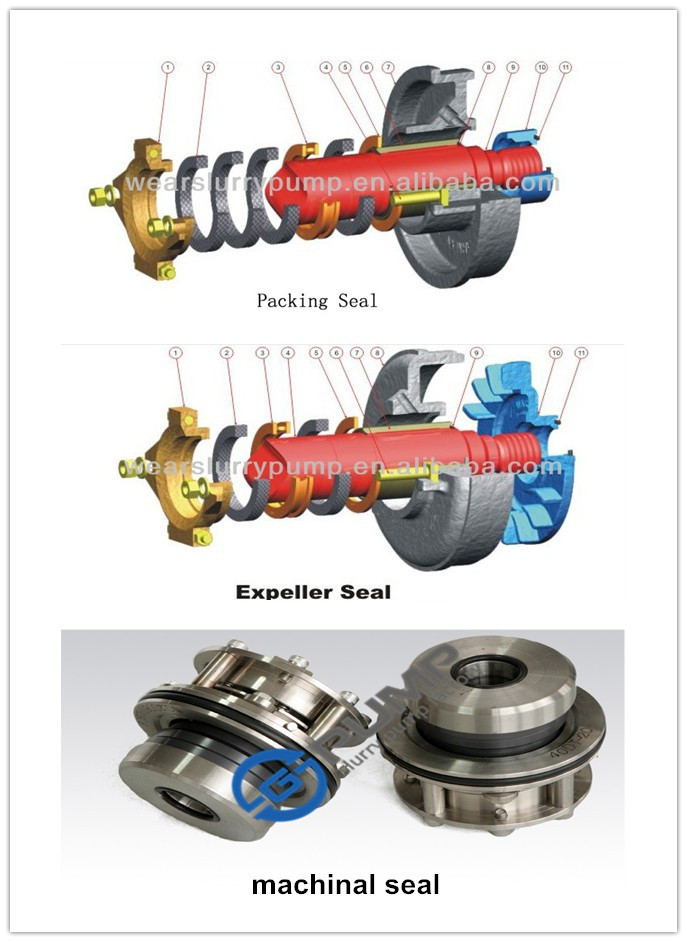

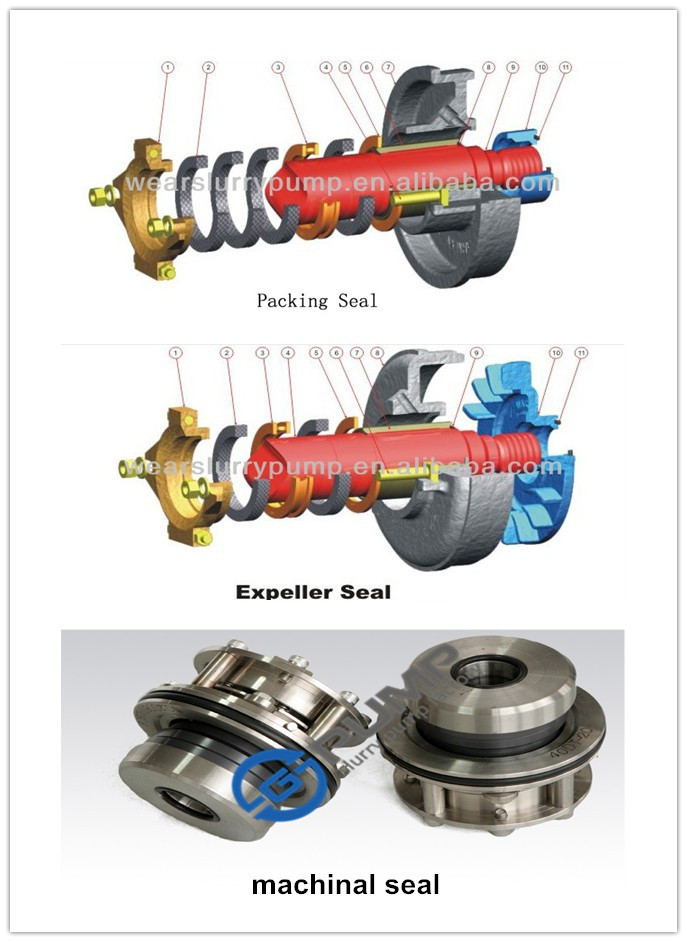

Seal Type There are three standard shaft seal methods: Packing seal, Expeller seal, Mechanical seal. Packing Seal :

Seal Type There are three standard shaft seal methods: Packing seal, Expeller seal, Mechanical seal. Packing Seal :

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal : MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications.

Spare Parts We guarantee highest quality spare parts readily available to service for your process running. OEM or upgraded specification spare parts, coupled with full engineering design capability, will ensure reliability and optimimal performance time. Many of our slurry pump components, including impellers,frame & back liners,seals,bearing housings and bases. All slurry pump spare parts are 100% interchangeable with Warman & Weir pump brands. You will save your cost and time by working with our slurry pump. The material of spare parts are high chrome alloy or rubber and polyurethane.All are anti-wear and corrosion resistant.

High Chrome Alloy Spare Parts Natural Rubber Spare Parts

Natural Rubber Spare Parts  Polyurethane Spare Parts

Polyurethane Spare Parts

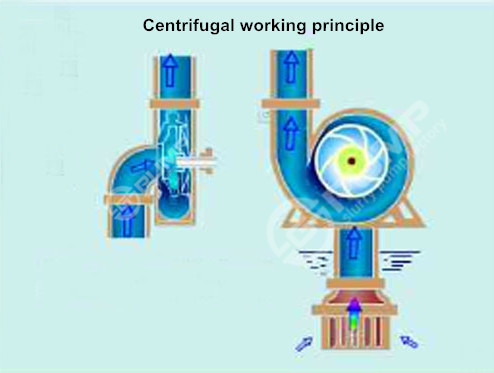

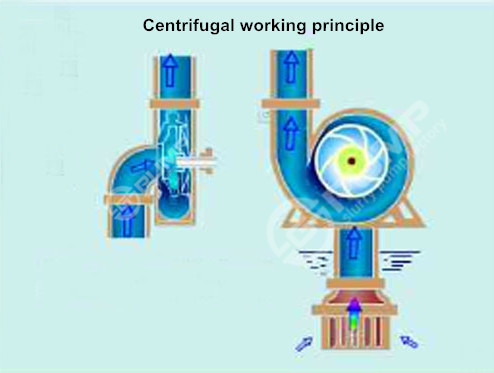

Application Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

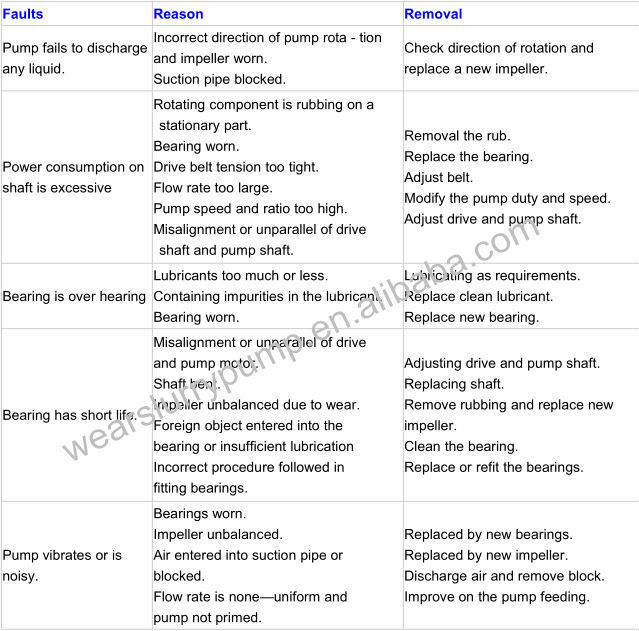

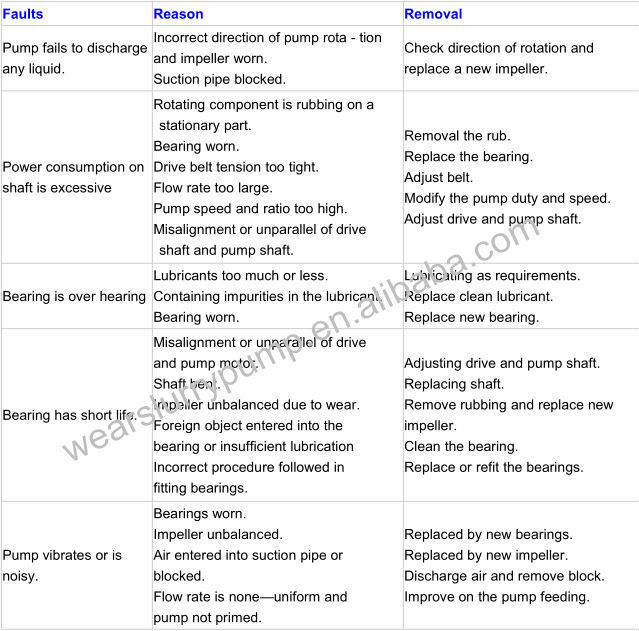

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

About us Shijiazhuang Gravel Slurry Pump Industry Co.,Ltd is a huge manufacturer of slurry pump, Gravel sand pump, Dredging pump, Chemical pump, Multistage pump, Split case pump, Water pump, Submersible sewage pump and pump spares which are widely used in mining, metallurgy, coal washery, power plant, sewage water treatment, dredging, and chemical and petroleum industry.

Contact us Welcome to contact us! Fax:+86-311-83050889 Tel: +86-311-85026467 Mobile: +86-18332008404 Skype: slurrypumpsupplier

Contact us Welcome to contact us! Fax:+86-311-83050889 Tel: +86-311-85026467 Mobile: +86-18332008404 Skype: slurrypumpsupplier

Email: sales2atgsslurrypump.com

MG Gravel Pump Component Diagram:

MG Gravel Pump Performance Chart:

MG Gravel Pump Performance Chart:  MG Gravel Pump Performance Data Sheet:

MG Gravel Pump Performance Data Sheet: Seal Type There are three standard shaft seal methods: Packing seal, Expeller seal, Mechanical seal. Packing Seal :

Seal Type There are three standard shaft seal methods: Packing seal, Expeller seal, Mechanical seal. Packing Seal :As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal : MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications.

Spare Parts We guarantee highest quality spare parts readily available to service for your process running. OEM or upgraded specification spare parts, coupled with full engineering design capability, will ensure reliability and optimimal performance time. Many of our slurry pump components, including impellers,frame & back liners,seals,bearing housings and bases. All slurry pump spare parts are 100% interchangeable with Warman & Weir pump brands. You will save your cost and time by working with our slurry pump. The material of spare parts are high chrome alloy or rubber and polyurethane.All are anti-wear and corrosion resistant.

High Chrome Alloy Spare Parts

Natural Rubber Spare Parts

Natural Rubber Spare Parts  Polyurethane Spare Parts

Polyurethane Spare Parts

Application Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

About us Shijiazhuang Gravel Slurry Pump Industry Co.,Ltd is a huge manufacturer of slurry pump, Gravel sand pump, Dredging pump, Chemical pump, Multistage pump, Split case pump, Water pump, Submersible sewage pump and pump spares which are widely used in mining, metallurgy, coal washery, power plant, sewage water treatment, dredging, and chemical and petroleum industry.

Contact us Welcome to contact us! Fax:+86-311-83050889 Tel: +86-311-85026467 Mobile: +86-18332008404 Skype: slurrypumpsupplier

Contact us Welcome to contact us! Fax:+86-311-83050889 Tel: +86-311-85026467 Mobile: +86-18332008404 Skype: slurrypumpsupplier Email: sales2atgsslurrypump.com

Supplier Information

Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

[ Hebei China ]

- Business Type : Trade Company

- Product/Service : slurry pump , gravel pump , sand pump

- Tel : 15832159591

More > Other products from this company