Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

Basic Information

- Model No.: MV

- Packaging: Wooden case or as the buyes request

- Place of Origin: Hebei, China (Mainland)

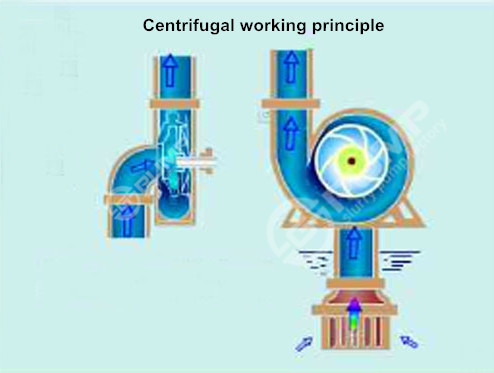

- Brand: ShiAo

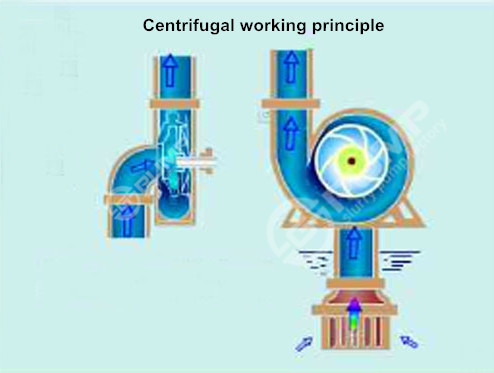

Centrifugal electric with agitaror submersible concrete slurry pump Product Description Description Vertical submersible concrete slurry pumps are vertical and centrifugal slurry pumps, which work submerged to transport the abrasive and high—density slurry with large articles. The pumps have no need for any shaft seal and sealing water. They can also run under the conditions of inadequate suction duty.  Features 1.Long wear life 2.High efficiency 3.Excellent suction performance 4.Ease maintenance 5. high efficiency, stable perform 6.Competitive price 7.Short lead time 8.100% interchangeable The stucture drawing Vertical submersible water slurry pump with extended—length shaft (L series) is suitable to operate in deep level in liquid. Guide bearing is added on this pump to make its operation more stable and flushing water should be fixed at the position of guide bearing.

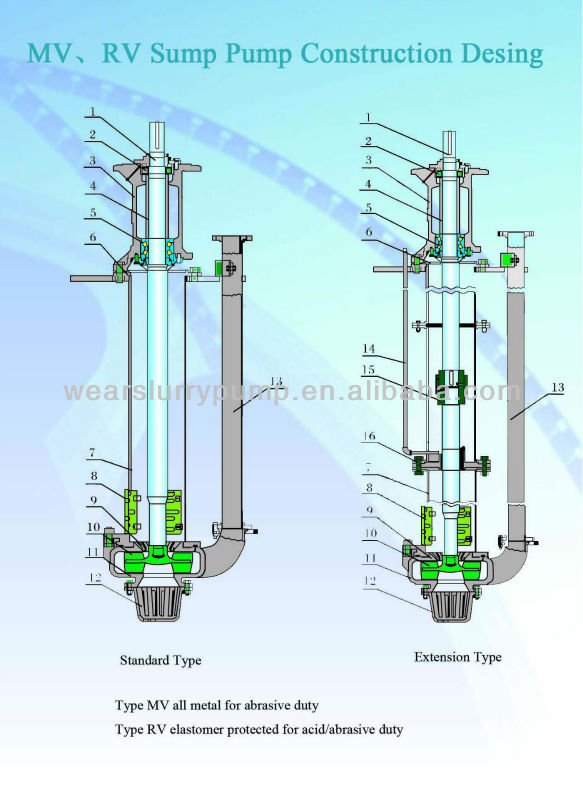

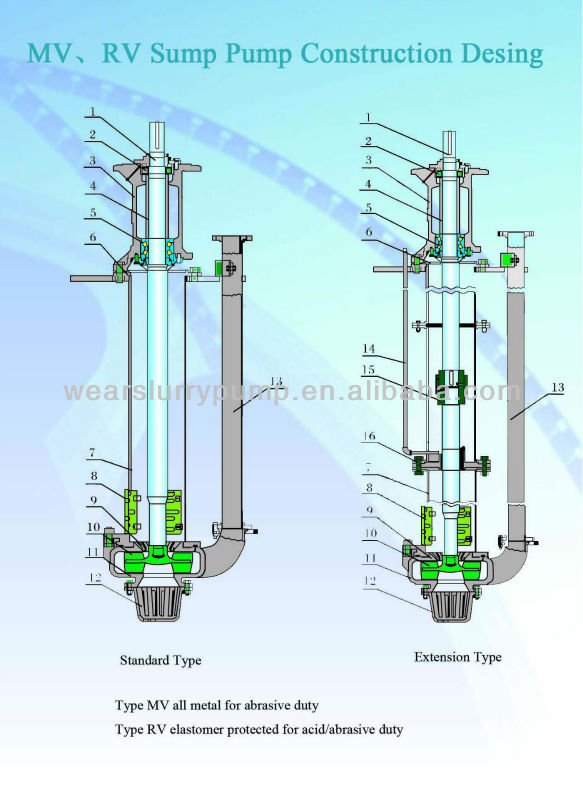

Features 1.Long wear life 2.High efficiency 3.Excellent suction performance 4.Ease maintenance 5. high efficiency, stable perform 6.Competitive price 7.Short lead time 8.100% interchangeable The stucture drawing Vertical submersible water slurry pump with extended—length shaft (L series) is suitable to operate in deep level in liquid. Guide bearing is added on this pump to make its operation more stable and flushing water should be fixed at the position of guide bearing.

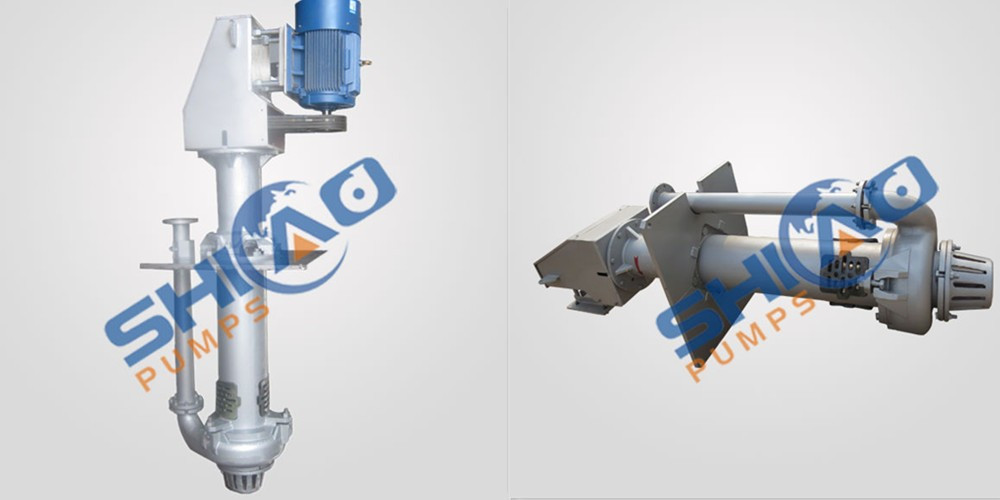

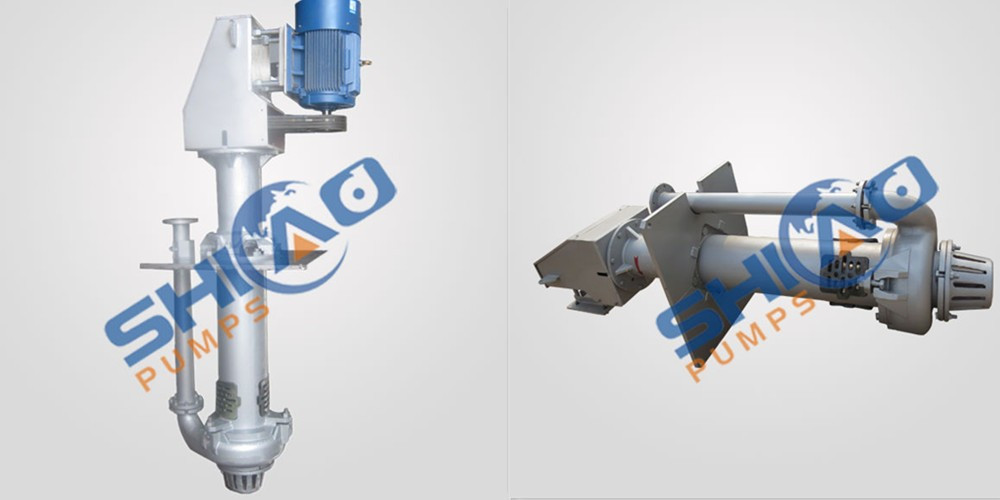

Way of installation The motor has two ways of installing Twe ways as follows drawing:

Way of installation The motor has two ways of installing Twe ways as follows drawing:  Spare parts Bearing assembly - a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. Liners - easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal ring back all liner joints. Casing - Casing halves of cast or ductile iron with exernal reinforcing ribs provide high operating pressure capabilities and extra measure of safety. Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomrer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. Throatbush - wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. Pump Base - a very robust onepiece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance

Spare parts Bearing assembly - a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. Liners - easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal ring back all liner joints. Casing - Casing halves of cast or ductile iron with exernal reinforcing ribs provide high operating pressure capabilities and extra measure of safety. Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomrer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. Throatbush - wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. Pump Base - a very robust onepiece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance

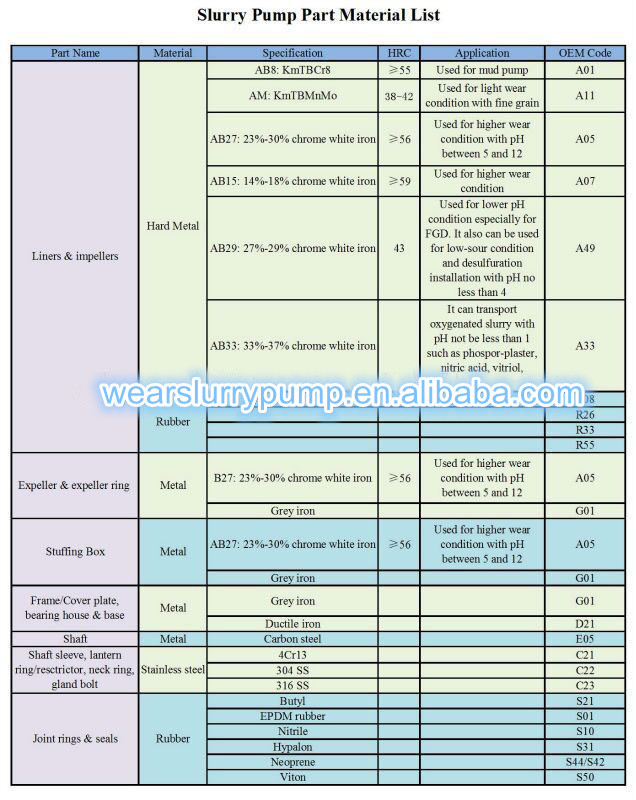

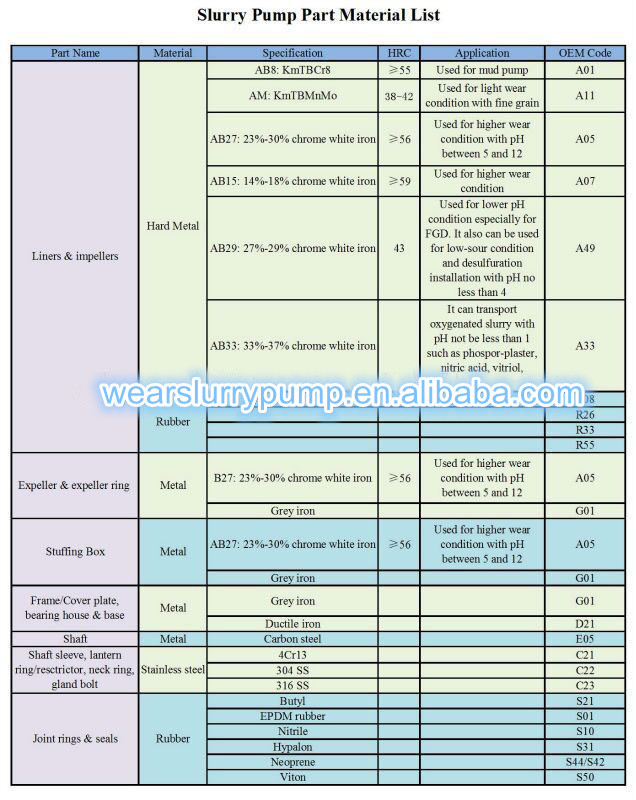

Slurry pump's pare parts description

Slurry pump's pare parts description  Application Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

Application Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

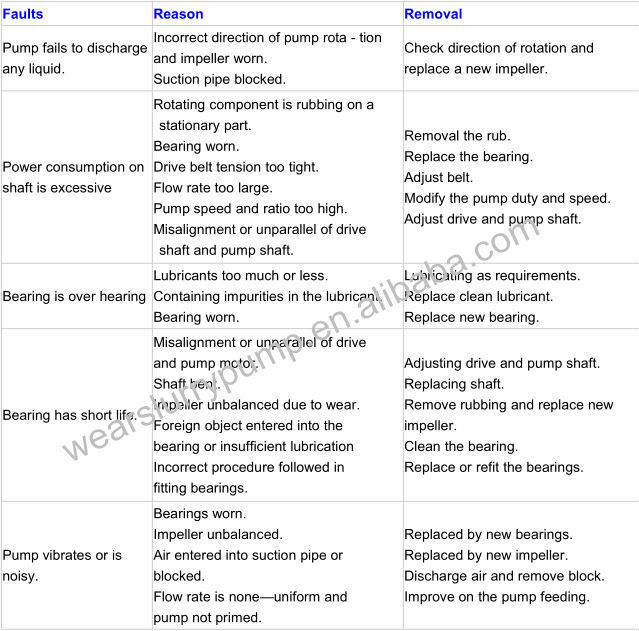

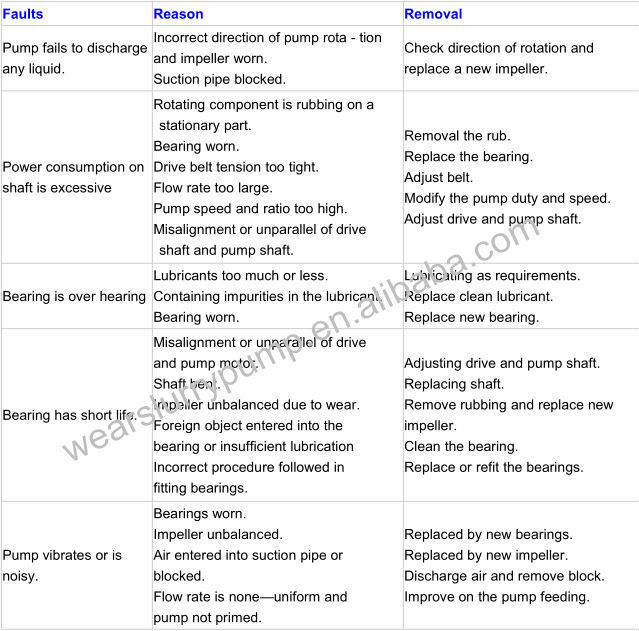

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Processing&Workshop Slurry pump's processing Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.

Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.  Packing&Shipping We package our slurry pumps and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard. Also we have professional workers to do these cases. We are very near to Tianjin port, so it is comfortable to deliver anytime, also can save the cost.

Packing&Shipping We package our slurry pumps and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard. Also we have professional workers to do these cases. We are very near to Tianjin port, so it is comfortable to deliver anytime, also can save the cost.  Contact us Welcome to contact us!

Contact us Welcome to contact us!

Features 1.Long wear life 2.High efficiency 3.Excellent suction performance 4.Ease maintenance 5. high efficiency, stable perform 6.Competitive price 7.Short lead time 8.100% interchangeable The stucture drawing Vertical submersible water slurry pump with extended—length shaft (L series) is suitable to operate in deep level in liquid. Guide bearing is added on this pump to make its operation more stable and flushing water should be fixed at the position of guide bearing.

Features 1.Long wear life 2.High efficiency 3.Excellent suction performance 4.Ease maintenance 5. high efficiency, stable perform 6.Competitive price 7.Short lead time 8.100% interchangeable The stucture drawing Vertical submersible water slurry pump with extended—length shaft (L series) is suitable to operate in deep level in liquid. Guide bearing is added on this pump to make its operation more stable and flushing water should be fixed at the position of guide bearing.

Way of installation The motor has two ways of installing Twe ways as follows drawing:

Way of installation The motor has two ways of installing Twe ways as follows drawing:  Spare parts Bearing assembly - a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. Liners - easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal ring back all liner joints. Casing - Casing halves of cast or ductile iron with exernal reinforcing ribs provide high operating pressure capabilities and extra measure of safety. Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomrer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. Throatbush - wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. Pump Base - a very robust onepiece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance

Spare parts Bearing assembly - a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. Liners - easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal ring back all liner joints. Casing - Casing halves of cast or ductile iron with exernal reinforcing ribs provide high operating pressure capabilities and extra measure of safety. Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomrer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. Throatbush - wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. Pump Base - a very robust onepiece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance

Slurry pump's pare parts description

Slurry pump's pare parts description  Application Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

Application Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Problem&Remove Some problems may arise in the process of slurry pump's application.According to the production and the client appliction experience for many years,we give the following solutions:

Processing&Workshop Slurry pump's processing

Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.

Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.  Packing&Shipping We package our slurry pumps and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard. Also we have professional workers to do these cases. We are very near to Tianjin port, so it is comfortable to deliver anytime, also can save the cost.

Packing&Shipping We package our slurry pumps and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard. Also we have professional workers to do these cases. We are very near to Tianjin port, so it is comfortable to deliver anytime, also can save the cost.  Contact us Welcome to contact us!

Contact us Welcome to contact us!

Supplier Information

Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

[ Hebei China ]

- Business Type : Trade Company

- Product/Service : slurry pump , gravel pump , sand pump

- Tel : 15832159591

More > Other products from this company