Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

Basic Information

- Model No.: SP65QV

- Packaging: wooden case or as client\'s request

- Place of Origin: Hebei, China (Mainland)

- Brand: GS

Company Information Shijiazhuang Gravel Slurry Pump Industry Co.,ltd locates in Shijiazhuang, Hebei Province, China, it is an integrative production, research, design and sales company, specialized in manufacturing slurry pump products. The company acting as one of the national heavy machinery industry unit, now has been developed into a professional manufacturer of slurry pump, mud pump, slush pump, foam pump, sand-slurry pump.Submersible vertical slurry pumping machine for river mud and sand dredging

Product Description: 1)This series submersible slurry pump are cantilevered vertical slurry pump, working in pools. 2)The Vertical Centrifugal Slurry pump is mainly used for delivery the slurry which is strong corrosion and high concentration strong corrosive with fine particles. 3) light weight, small volume, easy installation for the Vertical Centrifugal Slurry pump 4) The Wet parts of this series Vertical Centrifugal Slurry pump p are made of wear-resistant metal. 5)The submersible parts are with outer lining. It is suitable for delivering the slurry which is strong corrosion and high concentration strong corrosive with fine particles. 6) The character “L” means lengthening guide bearing. It is used for the deep water situation with good performance and wide range of usage. The guide bearing part should equipped with flushing water system. Submersible vertical slurry pumping machine for river mud and sand dredging feature: -Fully elastomer lined or hard metal fitted

Product Description: 1)This series submersible slurry pump are cantilevered vertical slurry pump, working in pools. 2)The Vertical Centrifugal Slurry pump is mainly used for delivery the slurry which is strong corrosion and high concentration strong corrosive with fine particles. 3) light weight, small volume, easy installation for the Vertical Centrifugal Slurry pump 4) The Wet parts of this series Vertical Centrifugal Slurry pump p are made of wear-resistant metal. 5)The submersible parts are with outer lining. It is suitable for delivering the slurry which is strong corrosion and high concentration strong corrosive with fine particles. 6) The character “L” means lengthening guide bearing. It is used for the deep water situation with good performance and wide range of usage. The guide bearing part should equipped with flushing water system. Submersible vertical slurry pumping machine for river mud and sand dredging feature: -Fully elastomer lined or hard metal fitted

-Double suction semi-open impeller

-No submerged bearing or packing

-Optional recessed impeller and suction agitator available

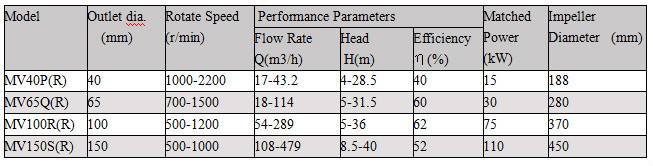

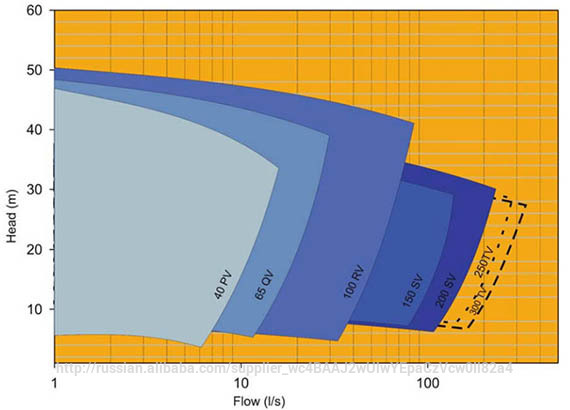

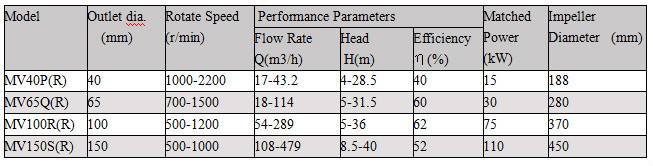

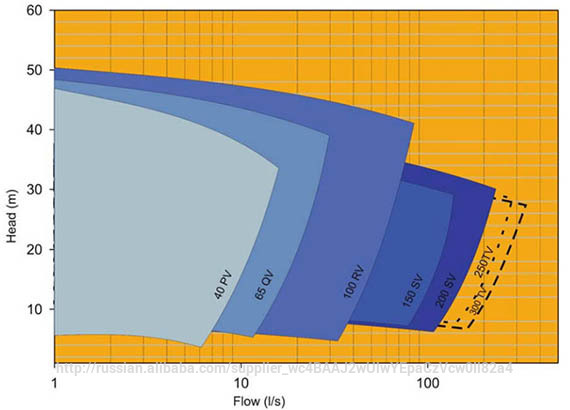

-MV models feature full rubber covering for corrosion resistance -Can be run in insufficient suction duties Submersible vertical slurry pumping machine for river mud and sand dredging parameter selection: Outlet: 40-300mm

Capacity: to 1548 m³/h

Head: to 40 m

Type: Centrifugal, Vertical, single Casing

Wet Parts Materials: Natural rubber

Replacement: Interchangeable with other pumps dimensionally

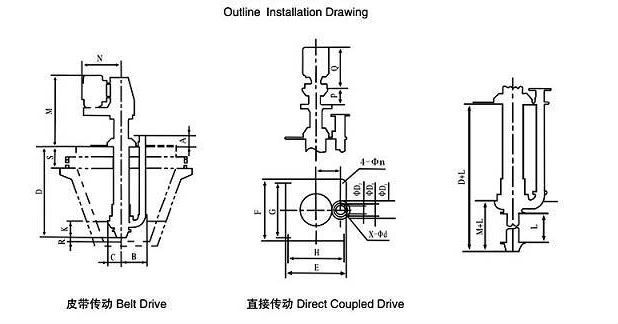

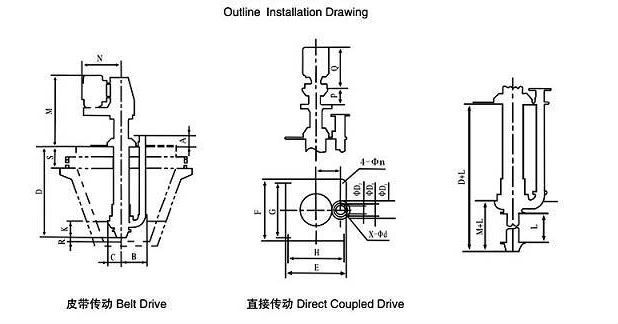

Submersible vertical slurry pumping machine for river mud and sand dredging structure:

Submersible vertical slurry pumping machine for river mud and sand dredging structure:

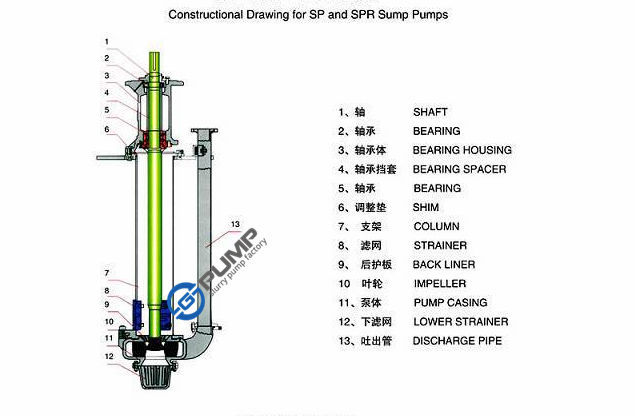

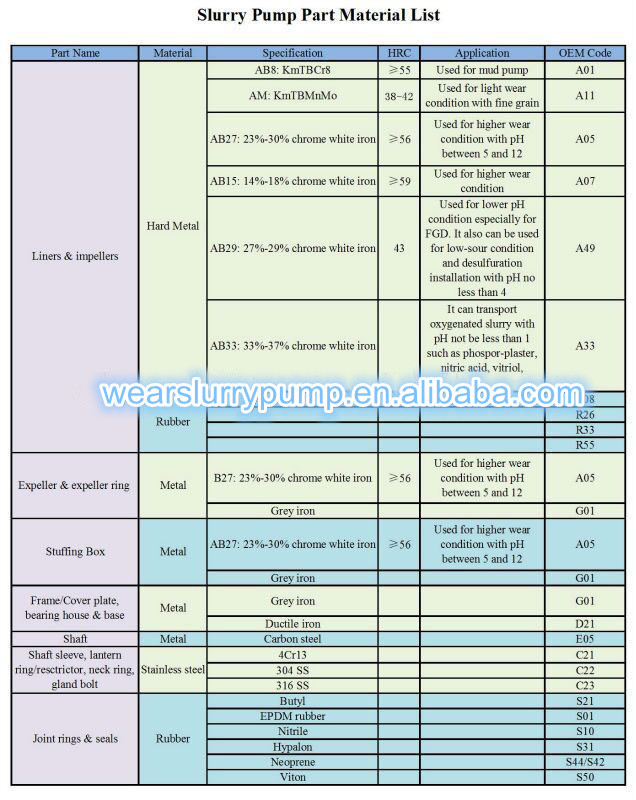

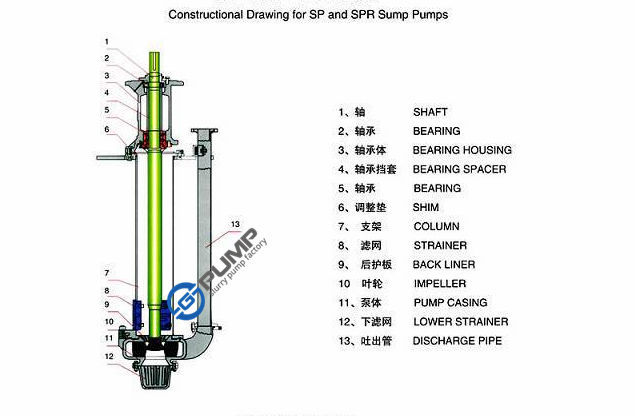

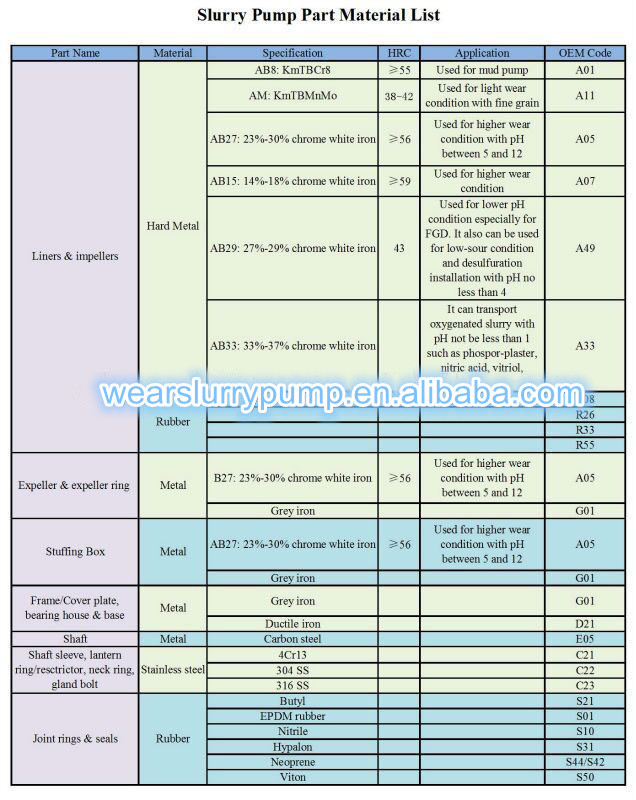

component diagram.. Submersible vertical slurry pumping machine for river mud and sand dredging spare parts: 1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity. 2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance. 3. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life. 4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety. 5. All of the rubber parts have superior erosion resisting performance which can be used for a long life.

component diagram.. Submersible vertical slurry pumping machine for river mud and sand dredging spare parts: 1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity. 2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance. 3. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life. 4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety. 5. All of the rubber parts have superior erosion resisting performance which can be used for a long life.

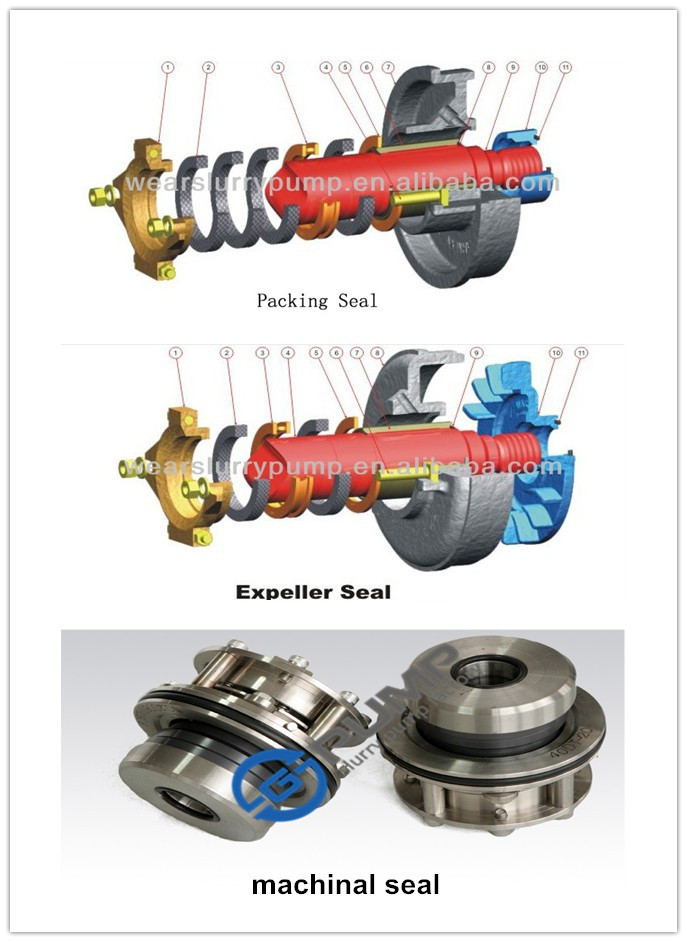

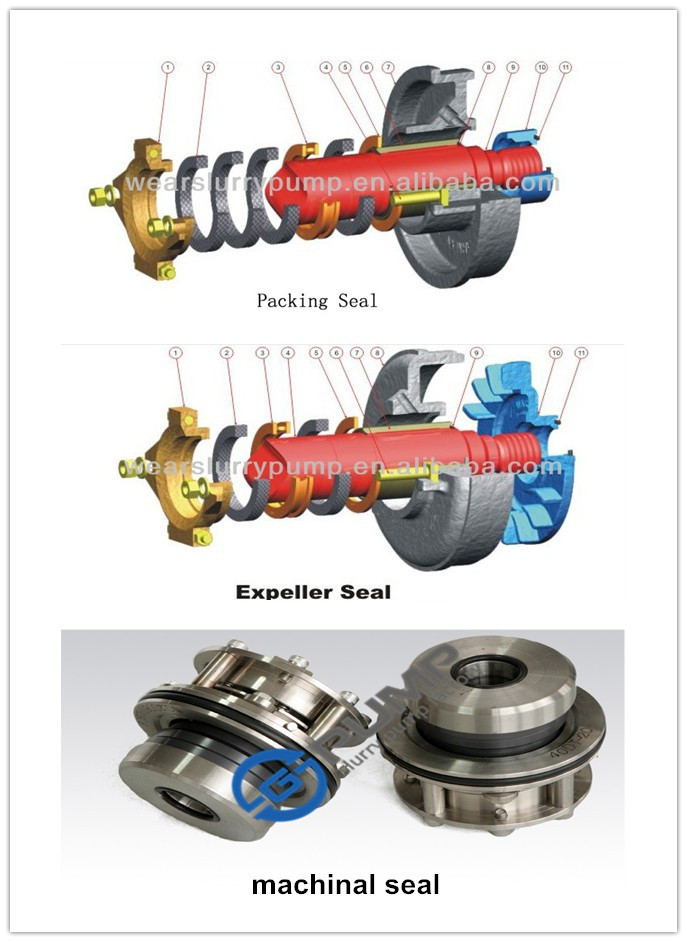

shaft seal: Packing Seal :

shaft seal: Packing Seal :

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal :

MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications. We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction. Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions. related product: We can produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting. Such as following type: 1. MH(RH)series Metal/ Rubber Lined Horizontal Slurry Pump 2. MMseries Medium Duty Slurry Pump 3. ML(LR) series Low Abrasive Slurry Pump

related product: We can produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting. Such as following type: 1. MH(RH)series Metal/ Rubber Lined Horizontal Slurry Pump 2. MMseries Medium Duty Slurry Pump 3. ML(LR) series Low Abrasive Slurry Pump

4. GH series High Head Slurry Pump

5.MG series Sand and Gravel Pump 6. ZJ/ ZJL series Filter Press Feed Pump 7. MV(R) series Vertical Slurry Pump 8.MF(R) series Vertical Froth Pump 9. ZGB series Heavy Slurry Pump 10. OEM series Slurry Pump

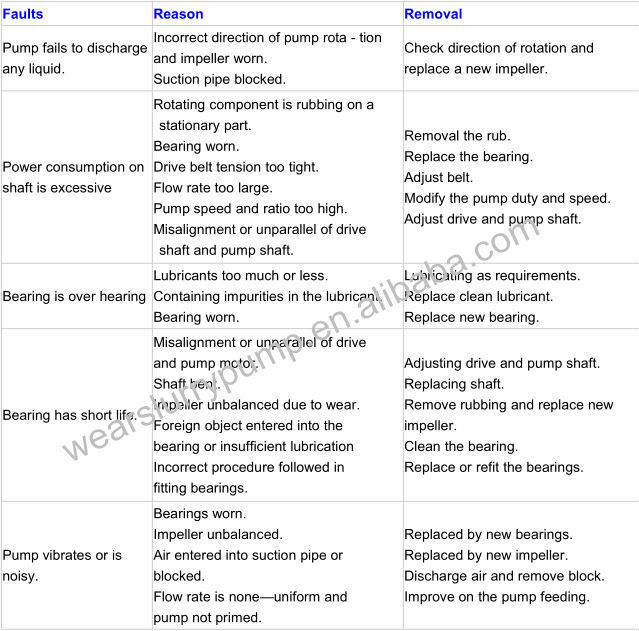

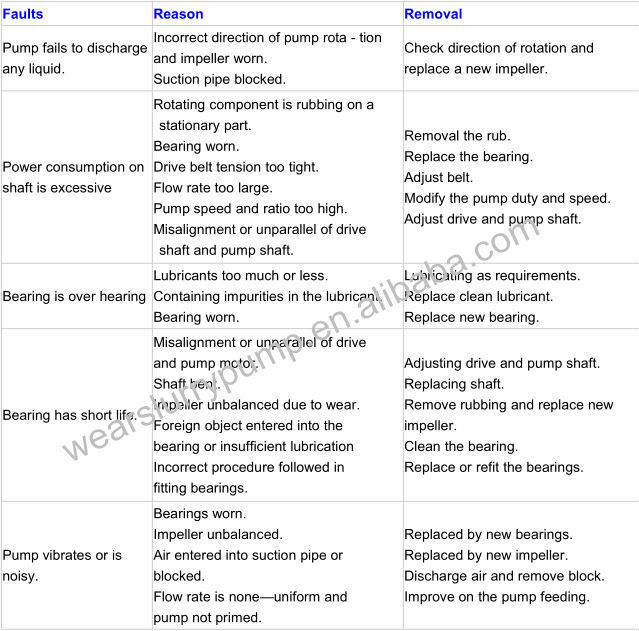

11. All Pump Spare Parts Problem and Solve in slurry pumps application:

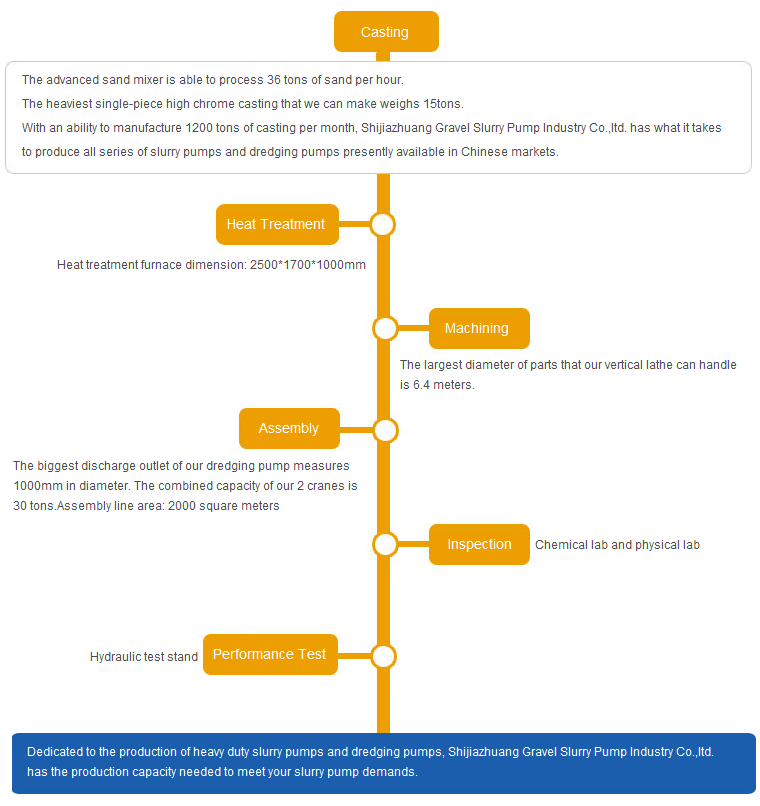

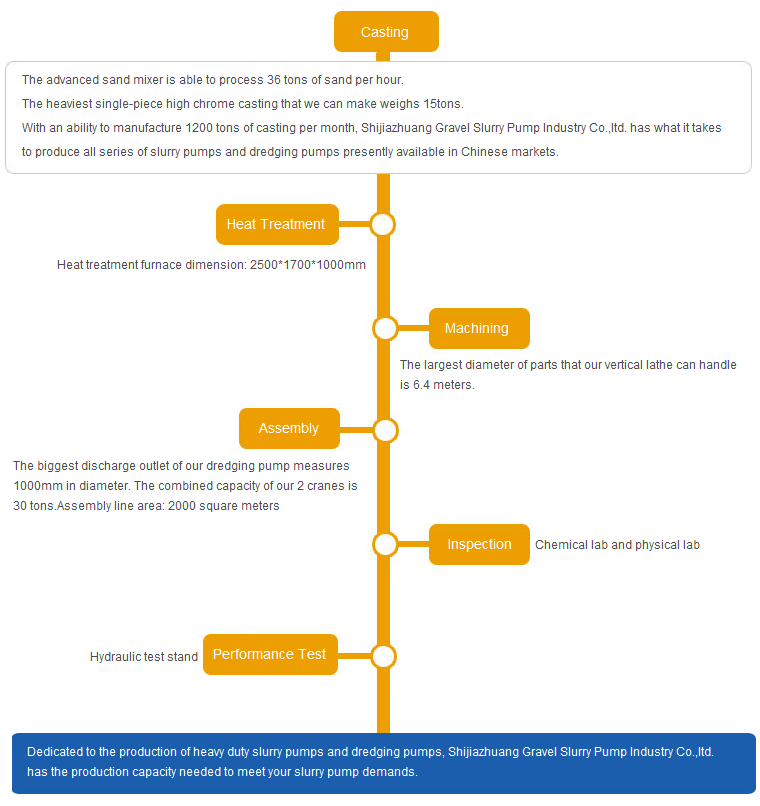

production process:

production process:  Applications of vertical slurry pump: The rugged MV,MVR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in:

Applications of vertical slurry pump: The rugged MV,MVR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in:

• Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Sand and gravel and almost every other tank, pit or hole-in-the-ground slurry handling situation. The MV/MVR design with either hard metal (MV) or elastomer covered (MVR) components makes it ideal for:

• Abrasive and/or corrosive slurries

• Large particle sizes

• High density slurries

• Continuous or “snore” operation

• Heavy duties demanding cantilever shafts packing and shipping:

packing and shipping:  Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. Why choose us: 1. About 30 years Design, produce and service experience. 2.High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate. 3.Good service. We have one of group high quality technicians who can help you solve any question during the process 4.Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon 5.Competitive price: As we are the direct factory. we have our casting workshop, machine workshop and Assembly Shop. 6.Rich export Experience. we had export USA, Germany,cannada , Austrilia and so on developed country and South africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high Reputation at home and abroad. Contact us

Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. Why choose us: 1. About 30 years Design, produce and service experience. 2.High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate. 3.Good service. We have one of group high quality technicians who can help you solve any question during the process 4.Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon 5.Competitive price: As we are the direct factory. we have our casting workshop, machine workshop and Assembly Shop. 6.Rich export Experience. we had export USA, Germany,cannada , Austrilia and so on developed country and South africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high Reputation at home and abroad. Contact us

Product Description: 1)This series submersible slurry pump are cantilevered vertical slurry pump, working in pools. 2)The Vertical Centrifugal Slurry pump is mainly used for delivery the slurry which is strong corrosion and high concentration strong corrosive with fine particles. 3) light weight, small volume, easy installation for the Vertical Centrifugal Slurry pump 4) The Wet parts of this series Vertical Centrifugal Slurry pump p are made of wear-resistant metal. 5)The submersible parts are with outer lining. It is suitable for delivering the slurry which is strong corrosion and high concentration strong corrosive with fine particles. 6) The character “L” means lengthening guide bearing. It is used for the deep water situation with good performance and wide range of usage. The guide bearing part should equipped with flushing water system. Submersible vertical slurry pumping machine for river mud and sand dredging feature: -Fully elastomer lined or hard metal fitted

Product Description: 1)This series submersible slurry pump are cantilevered vertical slurry pump, working in pools. 2)The Vertical Centrifugal Slurry pump is mainly used for delivery the slurry which is strong corrosion and high concentration strong corrosive with fine particles. 3) light weight, small volume, easy installation for the Vertical Centrifugal Slurry pump 4) The Wet parts of this series Vertical Centrifugal Slurry pump p are made of wear-resistant metal. 5)The submersible parts are with outer lining. It is suitable for delivering the slurry which is strong corrosion and high concentration strong corrosive with fine particles. 6) The character “L” means lengthening guide bearing. It is used for the deep water situation with good performance and wide range of usage. The guide bearing part should equipped with flushing water system. Submersible vertical slurry pumping machine for river mud and sand dredging feature: -Fully elastomer lined or hard metal fitted-Double suction semi-open impeller

-No submerged bearing or packing

-Optional recessed impeller and suction agitator available

-MV models feature full rubber covering for corrosion resistance -Can be run in insufficient suction duties Submersible vertical slurry pumping machine for river mud and sand dredging parameter selection: Outlet: 40-300mm

Capacity: to 1548 m³/h

Head: to 40 m

Type: Centrifugal, Vertical, single Casing

Wet Parts Materials: Natural rubber

Replacement: Interchangeable with other pumps dimensionally

Submersible vertical slurry pumping machine for river mud and sand dredging structure:

Submersible vertical slurry pumping machine for river mud and sand dredging structure:

component diagram.. Submersible vertical slurry pumping machine for river mud and sand dredging spare parts: 1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity. 2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance. 3. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life. 4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety. 5. All of the rubber parts have superior erosion resisting performance which can be used for a long life.

component diagram.. Submersible vertical slurry pumping machine for river mud and sand dredging spare parts: 1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity. 2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance. 3. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life. 4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety. 5. All of the rubber parts have superior erosion resisting performance which can be used for a long life.

shaft seal: Packing Seal :

shaft seal: Packing Seal :As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal :

MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications. We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction. Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions.

related product: We can produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting. Such as following type: 1. MH(RH)series Metal/ Rubber Lined Horizontal Slurry Pump 2. MMseries Medium Duty Slurry Pump 3. ML(LR) series Low Abrasive Slurry Pump

related product: We can produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting. Such as following type: 1. MH(RH)series Metal/ Rubber Lined Horizontal Slurry Pump 2. MMseries Medium Duty Slurry Pump 3. ML(LR) series Low Abrasive Slurry Pump4. GH series High Head Slurry Pump

5.MG series Sand and Gravel Pump 6. ZJ/ ZJL series Filter Press Feed Pump 7. MV(R) series Vertical Slurry Pump 8.MF(R) series Vertical Froth Pump 9. ZGB series Heavy Slurry Pump 10. OEM series Slurry Pump

11. All Pump Spare Parts Problem and Solve in slurry pumps application:

production process:

production process:  Applications of vertical slurry pump: The rugged MV,MVR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in:

Applications of vertical slurry pump: The rugged MV,MVR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in: • Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Sand and gravel and almost every other tank, pit or hole-in-the-ground slurry handling situation. The MV/MVR design with either hard metal (MV) or elastomer covered (MVR) components makes it ideal for:

• Abrasive and/or corrosive slurries

• Large particle sizes

• High density slurries

• Continuous or “snore” operation

• Heavy duties demanding cantilever shafts

packing and shipping:

packing and shipping:  Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. Why choose us: 1. About 30 years Design, produce and service experience. 2.High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate. 3.Good service. We have one of group high quality technicians who can help you solve any question during the process 4.Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon 5.Competitive price: As we are the direct factory. we have our casting workshop, machine workshop and Assembly Shop. 6.Rich export Experience. we had export USA, Germany,cannada , Austrilia and so on developed country and South africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high Reputation at home and abroad. Contact us

Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. Why choose us: 1. About 30 years Design, produce and service experience. 2.High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate. 3.Good service. We have one of group high quality technicians who can help you solve any question during the process 4.Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon 5.Competitive price: As we are the direct factory. we have our casting workshop, machine workshop and Assembly Shop. 6.Rich export Experience. we had export USA, Germany,cannada , Austrilia and so on developed country and South africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high Reputation at home and abroad. Contact us

Supplier Information

Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

[ Hebei China ]

- Business Type : Trade Company

- Product/Service : slurry pump , gravel pump , sand pump

- Tel : 15832159591

More > Other products from this company